Need Help for Motor or Pump Replacement

- Thread starter a0128958

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Friday, Aug. 5th update:

Today I received the new base from aqua-man.com. Yipee! It perfectly supports and fits a 56Y square flange motor. I've learned today that if you're going to replace a 48Y with a 56Y motor on a Sta-Rite Max-E-Glas II pump, purchase of a new base is fundamentally required.

With the new base installed under the volute, I completed overhauling the wet end of the pump. New pump seal, new diffuser, and replacement o-rings. Interesting how a pump seal works - never replaced one before.

Tomorrow it's the electrical side. I understand how to wire up a 2-speed motor, but, I'm not sure how to do the wiring in my Jandy AquaLink Control Center. I have a spare relay in it. I'll look tomorrow at some AquaLink instructional material. Need to figure out how to prevent high and low speed being energized simultaneously.

Best regards,

Bill

Today I received the new base from aqua-man.com. Yipee! It perfectly supports and fits a 56Y square flange motor. I've learned today that if you're going to replace a 48Y with a 56Y motor on a Sta-Rite Max-E-Glas II pump, purchase of a new base is fundamentally required.

With the new base installed under the volute, I completed overhauling the wet end of the pump. New pump seal, new diffuser, and replacement o-rings. Interesting how a pump seal works - never replaced one before.

Tomorrow it's the electrical side. I understand how to wire up a 2-speed motor, but, I'm not sure how to do the wiring in my Jandy AquaLink Control Center. I have a spare relay in it. I'll look tomorrow at some AquaLink instructional material. Need to figure out how to prevent high and low speed being energized simultaneously.

Best regards,

Bill

Sunday night, Aug. 7th update:

Milestone day! It looks like I have successfully replaced a single-speed 48Y frame sized motor on a Sta-Rite Max-E-Glas II pump with the best efficiency 2-speed motor on the market today (which happens to be a 56Y frame size).

I first started up the pump on high speed. Power went from 1890 watts (AO Smith single speed motor) to 2040 (AO Smith B2983 high speed), a 150 W increase. Pool filter pressure went from 27 to 32 psi.

On a temporary basis, until I figure out what I'm going to do with my AquaLink RS6 control center, I connected each of the 2-speed motor's speeds to an AquaLinkg relay. This allowed me to run the B2983 on low speed.

All works fine on low speed. I can start up from a dead stop (pump doesn't lose prime) without any problems. Pump power at low speed is 330 W. Assuming 230 VAC, that's about 1.4 Amps.

Initial examination shows that the 12 kWh I was consuming each day for pumps will drop to 7 kWh. So my daily savings is 5 kWh, assuming an apple-to-apples comparison of turning over the water once each day.

Still working on what I'm going to do in the AquaLink RS6 control panel. Looks like I need a $55 part, a SPDT relay that's addressable by the AquaLink's firmware.

So far my costs into this project are $330 (motor) + pump overhaul parts $35 + 56Y base $35, or about $400. A new SPDTT AuquaLink relay looks to be about $50.

Milestone day! It looks like I have successfully replaced a single-speed 48Y frame sized motor on a Sta-Rite Max-E-Glas II pump with the best efficiency 2-speed motor on the market today (which happens to be a 56Y frame size).

I first started up the pump on high speed. Power went from 1890 watts (AO Smith single speed motor) to 2040 (AO Smith B2983 high speed), a 150 W increase. Pool filter pressure went from 27 to 32 psi.

On a temporary basis, until I figure out what I'm going to do with my AquaLink RS6 control center, I connected each of the 2-speed motor's speeds to an AquaLinkg relay. This allowed me to run the B2983 on low speed.

All works fine on low speed. I can start up from a dead stop (pump doesn't lose prime) without any problems. Pump power at low speed is 330 W. Assuming 230 VAC, that's about 1.4 Amps.

Initial examination shows that the 12 kWh I was consuming each day for pumps will drop to 7 kWh. So my daily savings is 5 kWh, assuming an apple-to-apples comparison of turning over the water once each day.

Still working on what I'm going to do in the AquaLink RS6 control panel. Looks like I need a $55 part, a SPDT relay that's addressable by the AquaLink's firmware.

So far my costs into this project are $330 (motor) + pump overhaul parts $35 + 56Y base $35, or about $400. A new SPDTT AuquaLink relay looks to be about $50.

Wed., Aug. 10th Update:

The new 2-speed pump continues to run at about 330 W. Assuming 230 VAC, that's 1.4 A.

I have the pump set to run for about 20 hours each day - on at 1:30 AM and off at 9:30 PM. I don't have any way of knowing if I'm getting one complete water turnover for my 30 kgal pool for this time period. I'm going to research getting a flow meter instrument. Any suggestions from anyone would be appreciated.

Now that I've ran with exclusively running low speed for a few days, I know now there aren't any situations where I lose prime on the low-speed filter pump motor. My Polaris 280 pool cleaner works fine (runs for 6 hours daily), and switching to Spa mode 30 minutes each day (to circulate the spa water daily) works fine.

My utility cost saving looks to be about $180 per year (@ 10¢/kWh). I've gone from an average of 15 to 10 kWh per day (other pumps run during the day). Once I determine how many hours I need to do one complete turnover, this may shorten up the time the low-speed filter motor is running.

One area I'm not sure about yet is skimmer action of leaves. It's obviously not as strong. But it's not clear yet if it will be inadequate. I don't want to turn off the main drain because I don't want the water to only circulate from the return nozzles to the skimmers. I still have yet to figure out the strategy for main drain suction vs skimmer (3 total) suction version some combination. Right now all four line are wide open.

The other area I'm not sure about is algae growth. So far so good. I don't usually have problems, especially noting that I do a good job keeping the chemistry where it should be, including being generally + or - one-tenth of SI=0. At the moment I have my chlorination set to maintain about 5 ppm. Still, there's much less turbulance in the water, and I don't know how well the water's being turned over.

I ordered the Jandy 2-speed relay (6796) that will prevent me from turning on both high and low motor speeds. It also will allow me to program high speed usage if I want it. Interesting how huge the price variation is for this part. I ordered it from H20Poolroducts.com at $34. Some advertise it for $180. The rest advertise it somewhere in between.

Best regards,

Bill

The new 2-speed pump continues to run at about 330 W. Assuming 230 VAC, that's 1.4 A.

I have the pump set to run for about 20 hours each day - on at 1:30 AM and off at 9:30 PM. I don't have any way of knowing if I'm getting one complete water turnover for my 30 kgal pool for this time period. I'm going to research getting a flow meter instrument. Any suggestions from anyone would be appreciated.

Now that I've ran with exclusively running low speed for a few days, I know now there aren't any situations where I lose prime on the low-speed filter pump motor. My Polaris 280 pool cleaner works fine (runs for 6 hours daily), and switching to Spa mode 30 minutes each day (to circulate the spa water daily) works fine.

My utility cost saving looks to be about $180 per year (@ 10¢/kWh). I've gone from an average of 15 to 10 kWh per day (other pumps run during the day). Once I determine how many hours I need to do one complete turnover, this may shorten up the time the low-speed filter motor is running.

One area I'm not sure about yet is skimmer action of leaves. It's obviously not as strong. But it's not clear yet if it will be inadequate. I don't want to turn off the main drain because I don't want the water to only circulate from the return nozzles to the skimmers. I still have yet to figure out the strategy for main drain suction vs skimmer (3 total) suction version some combination. Right now all four line are wide open.

The other area I'm not sure about is algae growth. So far so good. I don't usually have problems, especially noting that I do a good job keeping the chemistry where it should be, including being generally + or - one-tenth of SI=0. At the moment I have my chlorination set to maintain about 5 ppm. Still, there's much less turbulance in the water, and I don't know how well the water's being turned over.

I ordered the Jandy 2-speed relay (6796) that will prevent me from turning on both high and low motor speeds. It also will allow me to program high speed usage if I want it. Interesting how huge the price variation is for this part. I ordered it from H20Poolroducts.com at $34. Some advertise it for $180. The rest advertise it somewhere in between.

Best regards,

Bill

- May 3, 2007

- 16,954

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

If your previous flow rate was 85 GPM, the low speed would be half of that. What is your filter presssure on high speed and how high is the pad relative to the water level?

mas985 said:If your previous flow rate was 85 GPM, the low speed would be half of that. What is your filter presssure on high speed and how high is the pad relative to the water level?

I just guessed that my (hi speed) flow was 85 GPM, based on my old single-speed (AO Smith USQ1202) being a 2.2 tHp motor in a Sta-Rite Max-E-Glas II P4EA6G pump. I don't know how to estimate flow rate more exactly.

Your comment is helpful - I didn't know flow volume is linearly a function of RPM.

To answer your specific question, my filter pressure is 27 psi in hi speed now (with the new AO Smith B2983 2-speed pump); it's 12 psi when in lo speed. (My pressure gage is small and old and thus these numbers could be off by a couple or so psi either way.)

My new 2-speed motor runs at 3450 / 1725 RPM. If my estimated 85 GPM on high speed is correct, then now I must be running at 42 GPM. Assuming 42, and noting I have a 30 KGal pool, then that means I need 706 minutes to turn over the water 1 complete cycle, or 12 hours of running the pump at low speed.

Since I'm instead running at 21 hrs/day, that means I'm actually excessively turning over the water (1.8X each day). So it looks like I can cut back the running of the new pump to achieve just a 1 turn over per day objective. 21 minus 12 hours = 9 hrs/day savings, @ 335 W = 3.0 kWh further savings per day = another $110/yr savings. Now my savings is up to $182 + 110 = $292/yr (@ 10¢/kWh).

I looked at putting in a flow meter to get an accurate idea of my water flow. Unfortunately the one's that could interface into my energy monitoring system (see my signature) are expensive and thus not something I'm going to do at this time.

If someone can help me estimate what my high speed flow rate is, based on the equipment in my signature, and based on these measurements, I'd be very appreciative.

Filter pressure: 27 psi (hi), 12 (lo)

Current: 10.0 Amps (hi), 1.5 (lo)

Motor nameplate numbers:

RPM: 3450 (hi), 1725 (lo)

Current: 10.0 Amps (hi), 1.6 (lo)

HP: 1.5 (hi), 0.19 (lo)

SF: 1.47 (hi and lo)

Thank you.

Best regards,

Bill

- May 3, 2007

- 16,954

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

My guess would be around 63 GPM on high and 32 GPM on low speed. I might be able to get a little closer if you can tell me the distance between the pool and the equipment plus how high the equipment pad is relative to the pool water.

mas985 said:My guess would be around 63 GPM on high and 32 GPM on low speed. I might be able to get a little closer if you can tell me the distance between the pool and the equipment plus how high the equipment pad is relative to the pool water.

This is much appreciated!

Distance from pad to center of pool is approx 50 feet. Pad is approx 1 foot higher than surface of pool water (pool has a deep end with diving board). All pipe sizing is in my signature.

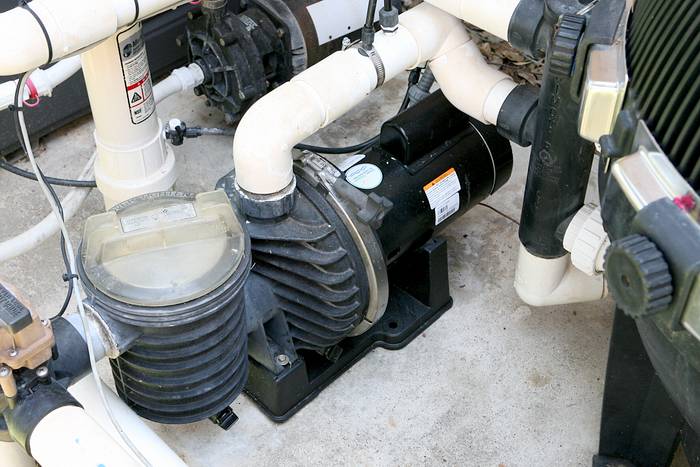

Here's an image of the pool equip (before making pump motor change):

(The Sta-Rite Max-E-Glas II pump that I replaced the single-speed Y48 motor with the 2-speed Y56 motor is in the middle (filter pump). The left most pump (just to the right of the pool heater) is the pool cleaner pump, and the right most pump is for the waterfall.)

Many thanks!

Best regards,

Bill

- May 3, 2007

- 16,954

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Using a more accurate head curve and your additional information, I now think the operating point is 69 GPM @ 72' of head and low speed is 34 GPM @ 18' of head.

The return side seem to have quite a bit of head loss. Assuming of course your gauge is reading correctly.

The return side seem to have quite a bit of head loss. Assuming of course your gauge is reading correctly.

mas985 said:Using a more accurate head curve and your additional information, I now think the operating point is 69 GPM @ 72' of head and low speed is 34 GPM @ 18' of head.

The return side seem to have quite a bit of head loss. Assuming of course your gauge is reading correctly.

Wow! Much appreciated! very helpful!

So let's see now - I can further save some money. At low speed, I now know I'm moving 34 GPM. For a 30 KGal pool, that means I need to run the filter pump on low speed at least 882 minutes each day to get a full turnover of water daily. That's 15 hours. At my current amount of time, 21 hours, that's 6 hours less, or stated in annual utility savings, that's an additional $73 annually (at 10 cents/kWh).

I'll reset the controller tonight for 15 hours per day for low speed filtration and see how it goes. Since I have solar PV generation, I'll center up the 15 hours around 2 PM to take max advantage of the electricity generation.

WRT to higher than expected filter pressure on the return side:

In my case I've got a backwash valve, a big 400 KBTU/hr heater, a 2" one-way valve, a 3-way Jandy Never-Lube valve, an in-and-out Jandy Never-Lube valve, and at least 50' of pipe all soaking up friction loss, so I'm not surprised my filter pressure is higher than expected. Thanks for increasing my awareness that it's somewhat high.

My filter pump pressure gage is old, and difficult to read, so this is a good opportunity to replace it with something a little more accurate.

Best regards,

Bill

OK, for those of you wanting some pictures, here are a couple.

First, here's what a Sta-Rite Max-E-Glas II pump looks like with the manufacturer supplied 48Y square flange single-speed motor. In this case it's a model P4EA6G pump with an AO Smith USQ1202 motor (total 2.2 HP). This pump was manufactured in 1992.

Note the base fully supports the motor and its seal plate to be perfectly aligned with the wet end of the pump such that there's no torque on the 4 bolts holding the seal plate to the pump's wet end. The base has a piece of rubber that the motor body rests on. The diameter of the opening in the base matches the motor's 48Y body diameter.

My mission was to accomplish two things: (1) replace the motor with a 2 speed unit, and (2) select the most energy efficient 2 speed unit I could find without limiting myself to just 48Y size motors.

The most energy efficient 2 speed motor I could find, regardless of physical size was the AO Smith E-Plus High Efficiency series. I selected model B2983 because its hi speed total HP matches my single speed's total HP exactly. It's the same motor as is advertised as the EcoMotor, and as is used in the EcoPump, and possibly the same as in the Pentair WhisperFlo. I paid $300 for it, from A1 Pool Parts, as recommended by many here.

Unfortunately the new 2 speed motor's size, 56Y, didn't match what I had (48Y). Thanks to many here, I worked through the details and figured out I needed to replace the base with another Sta-Rite base that only comes with 3 HP Sta-Rite pumps. Turns out at 3 HP, Sta-Rite changed to a 56Y size single speed motor.

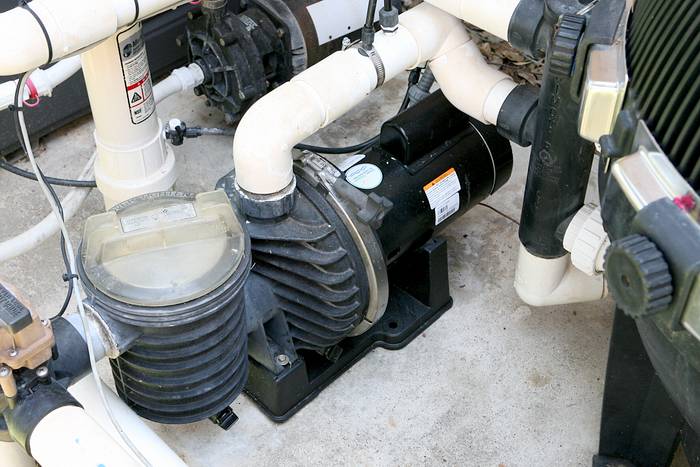

Here's the same pump now with the 56Y size 2-speed motor and the new Sta-Rite 3 HP base. Note that the new base looks almost identical to the earlier base. What you can't really see is that the diameter of the opening in the base is a little larger to snugly support the 56Y size motor. With the rubber support piece in place, the 56Y motor and its seal plate lines up perfectly to the pump's wet end, allowing for no downward torque on the 4 mounting bolts.

Hope this helps all those in the future who wonder if it's possible to replace 48Y with 56Y size motors for Sta-Rite pumps.

Best regards,

Bill

First, here's what a Sta-Rite Max-E-Glas II pump looks like with the manufacturer supplied 48Y square flange single-speed motor. In this case it's a model P4EA6G pump with an AO Smith USQ1202 motor (total 2.2 HP). This pump was manufactured in 1992.

Note the base fully supports the motor and its seal plate to be perfectly aligned with the wet end of the pump such that there's no torque on the 4 bolts holding the seal plate to the pump's wet end. The base has a piece of rubber that the motor body rests on. The diameter of the opening in the base matches the motor's 48Y body diameter.

My mission was to accomplish two things: (1) replace the motor with a 2 speed unit, and (2) select the most energy efficient 2 speed unit I could find without limiting myself to just 48Y size motors.

The most energy efficient 2 speed motor I could find, regardless of physical size was the AO Smith E-Plus High Efficiency series. I selected model B2983 because its hi speed total HP matches my single speed's total HP exactly. It's the same motor as is advertised as the EcoMotor, and as is used in the EcoPump, and possibly the same as in the Pentair WhisperFlo. I paid $300 for it, from A1 Pool Parts, as recommended by many here.

Unfortunately the new 2 speed motor's size, 56Y, didn't match what I had (48Y). Thanks to many here, I worked through the details and figured out I needed to replace the base with another Sta-Rite base that only comes with 3 HP Sta-Rite pumps. Turns out at 3 HP, Sta-Rite changed to a 56Y size single speed motor.

Here's the same pump now with the 56Y size 2-speed motor and the new Sta-Rite 3 HP base. Note that the new base looks almost identical to the earlier base. What you can't really see is that the diameter of the opening in the base is a little larger to snugly support the 56Y size motor. With the rubber support piece in place, the 56Y motor and its seal plate lines up perfectly to the pump's wet end, allowing for no downward torque on the 4 mounting bolts.

Hope this helps all those in the future who wonder if it's possible to replace 48Y with 56Y size motors for Sta-Rite pumps.

Best regards,

Bill

Mon., Aug. 15th Update:

The AquaLink 2-speed motor relay kit (Jandy 6796) arrived last week and yesterday I installed it into my AquaLink (All Button) RS6. Now I better understand why control of my newly installed 2-speed motor using this relay kit is a good idea.

I'm pleasantly surprised to learn that my AquaLink controller has some built-in programming for 2-speed pumps that can be turned on with a DIP switch setting.

Now my controller gives me a button specifically for Lo speed. I programmed it for a total of 15 hours each day. I removed all programming for Hi speed. I learned this morning that the controller starts up the motor in Hi speed, even though nothing is programmed for Hi speed, and then after 3 minutes shifts to Lo speed. Excellent! I no longer need to be concerned about starting up in Lo speed with resulting possible prime problems - the controller automatically inserts 3 minutes of Hi speed before ever going to Lo speed.

I also have my spa programmed to run 10 minutes daily to mix up the water each day. I wondered if the controller would be smart enough to insist on Hi speed even though I don't have any programming for Hi speed. Sure enough, even when running the motor on Lo speed, when the spa programmed time starts, the controller shifts the motor to Hi speed for the duration of the spa run period. In other words, the spa won't run with the motor in Lo speed. Excellent!

I've also shifted Freeze protection from the Hi to the Lo speed button. This Winter I'll find out if the controller runs the motor on Hi or Lo when the outside temp is below the Freeze setting. I'm hoping it's Lo as the flow is still sufficient from all cold days except for perhaps an exceptionally cold day.

One unexpected consequence of using the 2-speed relay kit is that it uses up another Aux function in my controller. So now I'm 'full up' for my RS6. And thus my eventual plan to replace my Waterfall motor with a 2-speed unit will have to include the expense of converting from an RS6 to an RS8 controller.

Best regards,

Bill

The AquaLink 2-speed motor relay kit (Jandy 6796) arrived last week and yesterday I installed it into my AquaLink (All Button) RS6. Now I better understand why control of my newly installed 2-speed motor using this relay kit is a good idea.

I'm pleasantly surprised to learn that my AquaLink controller has some built-in programming for 2-speed pumps that can be turned on with a DIP switch setting.

Now my controller gives me a button specifically for Lo speed. I programmed it for a total of 15 hours each day. I removed all programming for Hi speed. I learned this morning that the controller starts up the motor in Hi speed, even though nothing is programmed for Hi speed, and then after 3 minutes shifts to Lo speed. Excellent! I no longer need to be concerned about starting up in Lo speed with resulting possible prime problems - the controller automatically inserts 3 minutes of Hi speed before ever going to Lo speed.

I also have my spa programmed to run 10 minutes daily to mix up the water each day. I wondered if the controller would be smart enough to insist on Hi speed even though I don't have any programming for Hi speed. Sure enough, even when running the motor on Lo speed, when the spa programmed time starts, the controller shifts the motor to Hi speed for the duration of the spa run period. In other words, the spa won't run with the motor in Lo speed. Excellent!

I've also shifted Freeze protection from the Hi to the Lo speed button. This Winter I'll find out if the controller runs the motor on Hi or Lo when the outside temp is below the Freeze setting. I'm hoping it's Lo as the flow is still sufficient from all cold days except for perhaps an exceptionally cold day.

One unexpected consequence of using the 2-speed relay kit is that it uses up another Aux function in my controller. So now I'm 'full up' for my RS6. And thus my eventual plan to replace my Waterfall motor with a 2-speed unit will have to include the expense of converting from an RS6 to an RS8 controller.

Best regards,

Bill

- Jun 15, 2011

- 19

a0128958 said:Sunday night, Aug. 7th update:

I first started up the pump on high speed. Power went from 1890 watts (AO Smith single speed motor) to 2040 (AO Smith B2983 high speed), a 150 W increase. Pool filter pressure went from 27 to 32 psi.

Are you sure about this measurement? It would be disappointing that wet-end and all being equal, a new high efficiency motor needs 8% more electricity to do the same job as the old motor.

blackPlaster said:Are you sure about this measurement? It would be disappointing that wet-end and all being equal, a new high efficiency motor needs 8% more electricity to do the same job as the old motor.

Yes, I'm pretty sure on the numbers, as I have a pretty solid energy savings monitoring system ( http://www.welserver.com/WEL0043 ).

Some things to consider that could explain the performance increase: I overhauled the pump at the time I changed the motor. All new O-rings (diffuser, seal plate, impeller screw), new water slinger, and new shaft seal. Probably of most significance, though, was that I replaced the diffuser itself. It had a number of holes that had been worn through the plastic - it was 15 years old.

Power consumption is the highest right after a backwash when there's maximum flow. As the filter clogs up, power consumption falls as the flow slows down.

My guess is that the same phenomenom is being observed here after overhauling the pump. The pump's efficiency was significantly improved due to the maintenance performed on it, and thus the flow increased, and thus the power increased.

My new AO Smith 2-speed motor is advertised as an energy efficient Permanent Split Capacitor (PSC) hi-speed and an energy efficient Capacitor Start/Capacitor Run (CSCR) lo-speed, offering increased energy savings of up to 20% over regular 2-speed motors and up to 58% over regular 1 speed motors. My 2.2 THP model B2983 motor is advertised at 10.0 Amps Hi speed - my actual power measurement is 2040 Watts which is 8.9 Amps if you assume 230 Volts. At an advertised 1.6 Amps Lo speed, my actual power measurement is 335 Watts, which is 1.5 Amps.

Bottom line is that with a pretty good energy monitoring system, I'm seeing performance as advertised. I believe you'd see the same performance from the EcoPump or EcoMotor as I believe its the same motor, along with the WhisperFlo. And I'm not sure there's a more efficient 2 speed motor on the market at the moment - I think you have to go to permanent magnet technology variable speed motors to further gain on efficiency.

Best regards,

Bill

- May 3, 2007

- 16,954

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

The filter PSI should not have changed at all unless the impeller was clogged. And if that was the case, after clearing the clog, the wattage would have gone up.

jimvr4

0

This thread is very useful and dissappointing at the same time. I also need to move from a single speed pump built in 1998 which accounts for about 1/3 of my daily electrical usage. Unfortunately I also have a fully loaded Aqualink RS6. So it appears I have to upgrade to an RS8 in order to support a new two speed pump.

I don't have an independent pump for my RayVac cleaner - pressure is diverted from the main line prior to filtering and applied to a secondary filter before driving the RayVac. I would have to change the percentage of flow in the diverter to compensate for a lower flow. Any comments to this?

I don't have an independent pump for my RayVac cleaner - pressure is diverted from the main line prior to filtering and applied to a secondary filter before driving the RayVac. I would have to change the percentage of flow in the diverter to compensate for a lower flow. Any comments to this?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.