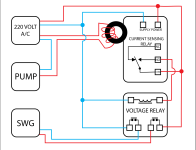

That is some amazing overkill building there, and I love it.2¢. Personally, I'd feel safer using a flow switch over a current sensing relay. The latter detects when the pump is using some amount of power, not that the impeller is actually moving water through the SWG. Only a flow switch can do that. And a flow switch is much cheaper, too. If you'd care to explore this idea, I can help you with the wiring.

If you really want a safe system, you'd use both, your sensor and a flow switch.

FWIW, I say "Personally, I'd feel safer using a flow switch over a current sensing relay" because that's exactly what I did. You can read about it here, complete with the schematic I designed (my circuit does things you don't need, and the flow switch is actually protecting against acid injection, not chlorine, but the function is the same, so you'd have to wade through the parts of it that don't apply to your application).

Hacking IntellipH to work in cold water

As Pentair IntellipH (IpH) automatic acid dosing system owners know, the IpH depends on a Pentair IntellliChlor (IC) saltwater chlorine generator. The IpH uses the IC's power supply, and monitors its flow switch, so that it won't dispense acid if the IC is reporting low flow. Unfortunately, it...www.troublefreepool.com

All that said, I commend you for adding any protection at all. A lot of people don't.

I will be using both the flow sensor on the SWG, and this relay, together to back each other up. If one fails, the other can take up the slack until I repair the issue.