Hey everyone, when it rains it pours... I recently opened my DE filter and am in the process of replacing the grids. Since the pump is off for the time being until the new DE filter grids arrived, I decided now was a good time to replace my spider valve gasket, which was also leaking somewhat.

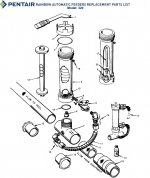

The good news is the spider gasket change seems to have gone well. I only have the tiniest of leaks coming out of the "waste" tube. The pump was running in "recirculate" mode to bypass the DE filter which has no manifold, no DE, and no DE grids in it. All was well, and I was monitoring the spider valve to make sure there were no leaks. Well, I have an old in-line chlorine tab chlorinator that decided to bite the dust. There is a black flexible device which extends off the side and wraps around to the bottom of the chlorinator which has disconnected from the upper connection point. Here are the pictures:

As a side note, you can also see there is no collar holding the halves of the DE filter together since I'm still waiting for the DE filter grids. What do y'all think I should do? Is there a way to bypass the chlorinator (which I don't use) without cutting PVC? If not, how realistic is it to install a salt water chlorine generator? I've been thinking about doing that for some time, so maybe now is the time?

Thanks for your help and guidance in advance!

-Jonathan

The good news is the spider gasket change seems to have gone well. I only have the tiniest of leaks coming out of the "waste" tube. The pump was running in "recirculate" mode to bypass the DE filter which has no manifold, no DE, and no DE grids in it. All was well, and I was monitoring the spider valve to make sure there were no leaks. Well, I have an old in-line chlorine tab chlorinator that decided to bite the dust. There is a black flexible device which extends off the side and wraps around to the bottom of the chlorinator which has disconnected from the upper connection point. Here are the pictures:

As a side note, you can also see there is no collar holding the halves of the DE filter together since I'm still waiting for the DE filter grids. What do y'all think I should do? Is there a way to bypass the chlorinator (which I don't use) without cutting PVC? If not, how realistic is it to install a salt water chlorine generator? I've been thinking about doing that for some time, so maybe now is the time?

Thanks for your help and guidance in advance!

-Jonathan