You need a licensed HVAC contractor who knows what they are doing and who has the correct license for the installation.

Below is information from the Mastertemp manual that you might find helpful.

In any case, get a licensed gas contractor to do it right.

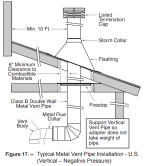

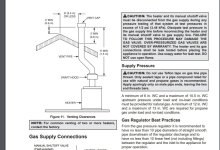

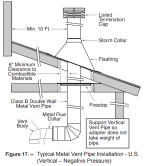

VERTICAL VENTING - NEGATIVE PRESSURE(See Figures 16, 17 and 18)Vent the heater vertically in a negative pressure (positive draft) system in accordance with the National Fuel Gas Code,ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and Propane Installation Codes, and local codes.

Type “B”Double-wall vent connector is recommended; however single-wall pipe is allowed by the National Fuel Gas Code in some circumstances.

Consult your local code official for detailed information.

Do not use a draft hood with this heater.

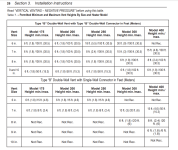

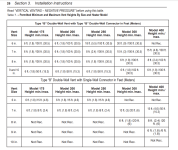

To connect a negative pressure metal gas vent to the heater, order the appropriate Metal Flue Collar from the chart below:

1. See Table 7, on page 26 to determine allowable vent sizes for your heater.

NOTICE: Table 7 is for installations in which the total lateral vent length (that is, the horizontal distance from the flue collar to the main vertical portion of the vent) is less than 1/2 the total vent height (the vertical distance from the flue collar to the vent termination) and which have three or less elbows in the system.

For venting systems which do not meet these conditions, consult the National Fuel Gas Code, ANSI Z223.1 (U.S.), or the standards CSA B149.1 and B149.2 (Canada).

The allowable vent runs for each vent pipe diameter are different and can not be exceeded.

Each 90-degree elbow reduces the maximum horizontal vent run by 12 feet and each 45-degree elbowin the vent run reduces the maximum vent run by 6 feet.

See Table 5 on page 24 for the maximum vent lengths using 90-degree and 45-degree elbows.

Install the metal Flue Collar in the Vent Body of the heater (located under the outside vent cover).

Fasten the metal Flue Collar to the Vent Body with two #10 sheetmetal screws.

Use high temperature silicone RTV to seal the Flue Collar to the Vent Body.

Before connecting the metal Flue Collar to the Vent Body, wet a clean cloth or paper towel with isopropyl alcohol (rubbing alcohol) and vigorously wipe the socket of the Vent Body.

Immediately wipe the cleaned surfaces dry with a clean cloth or paper towel.

Repeat for the exterior of the 4”end of the metal Flue Collar.

Attach the metal Flue Collar to the Vent Body using the RTV supplied with the kit, following the vent manufacturer’s instructions (included with kit).3.

Attach the vent pipe to the metal Flue Collar with sheet-metal screws

284. Install vent pipe so that it can expand and contract freely as the temperature changes.

Support the vent pipe according to applicable codes and the vent manufacturer’s instructions.

Pipe support must allow the vent pipe free movement out and back, from side to side, or up and down as necessary, without putting a strain on the heater or vent body.

Slope horizontal pipe runs up from the heater at least 1/4” per foot (2cm per meter).

Install Listed condensate drains at low points where condensate might collect.

Plumb condensate drains to a drain through hard piping or high temperature tubing such as silicone rubber or EPDM rubber – DO NOT USE VINYL OROTHER LOW TEMPERATURE TUBING. FOLLOW DRAIN MANUFACTURER’S INSTALLATIONINSTRUCTIONS.5.

Use Listed fire stop for floor and ceiling penetrations.

Use Listed thimble for wall penetrations.

Use a Listed roof flashing, roof jack, or roof thimble for all roof penetrations.

Do not fill the space around the vent (that is, the clear airspace in the thimble or fire stop) with insulation.

The roof opening must be located so that the vent is vertical.6.

Do not run the heater vent into a common vent with any other appliance.

Fire Hazard. Do not vent the heater directly into a masonry chimney.

Installation into a masonry chimney must use a chimney liner and must meet the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and Propane Installation Codes requirements and all local code requirements.

WARNING Risk of fire, carbon monoxide poisoning, or asphyxiation. It is recommended to use a CO Monitor and Fire Alarm in