Alright so I have (2) Jandy PLC 1400 SWCGs... I'm only going to focus on the second PLC 1400 for now.

6/12/23

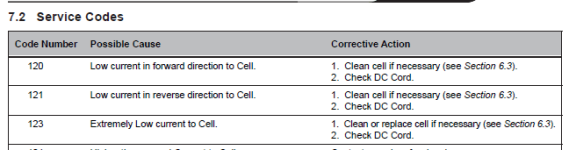

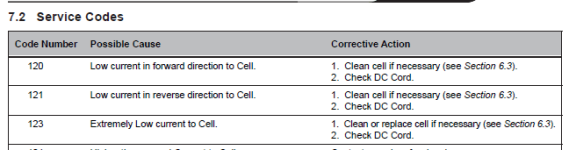

Noticed intermittent error code 123 (only in Reverse Flow, though it's intermittent, so the code isn't always showing every single Reverse Flow mode).

6/14/23

Replaced black power cord going to the cell.

6/15/23

Still showing intermittent 123 errors.

Replaced SWG cell unit (with Jandy/Zodiac brand).

6/17/23

Still showing intermittent 123 errors.

Ordered new back PCB board.

6/20/23

Still showing intermittent 123 errors.

Replaced back PCB board.

6/23/23

Still have not seen any 123 errors since replacing back PCB board. (checking 2-3x per day) - 3 days now, no 123 error

6/28/23

Still have not seen any 123 errors since replacing back PCB board. (checking 2-3x per day) - 8 days now, no 123 error

7/1/23

Still have not seen any 123 errors since replacing back PCB board. (checking 2-3x per day) --11 days now, no 123 error

7/2/23, 7/5/23, and 7/6/23

Suddenly seeing intermittent 121 errors - What the heck.....!?!

To recap so far I've replaced the main SWG cell unit, the power cord, and the back PCB. (I did not replace the Tri-Sensor Interface Module (since flow detection isn't an issue, there hasn't been any reason to)

Stumped here. 121 seems less problematic than 123 was but still doesn't make any sense why I'm getting that suddenly.

ANY IDEAS? (tried to call Jandy support today -- automated message of, "We're too busy, please try calling tomorrow".

Do I need to buy one of those Clamp Meters to be able to verify voltage and amperage during the error-free conditions versus when it's reporting the intermittent 121 error code?

Troubleshooting reference from install guide...

Thankfully my other SWG is still error free for now (was getting 171/189 codes on that cell (fixed by replacing the back PCB) and then later was getting 120 errors (fixed by 50/50 acid washing cell))

6/12/23

Noticed intermittent error code 123 (only in Reverse Flow, though it's intermittent, so the code isn't always showing every single Reverse Flow mode).

6/14/23

Replaced black power cord going to the cell.

6/15/23

Still showing intermittent 123 errors.

Replaced SWG cell unit (with Jandy/Zodiac brand).

6/17/23

Still showing intermittent 123 errors.

Ordered new back PCB board.

6/20/23

Still showing intermittent 123 errors.

Replaced back PCB board.

6/23/23

Still have not seen any 123 errors since replacing back PCB board. (checking 2-3x per day) - 3 days now, no 123 error

6/28/23

Still have not seen any 123 errors since replacing back PCB board. (checking 2-3x per day) - 8 days now, no 123 error

7/1/23

Still have not seen any 123 errors since replacing back PCB board. (checking 2-3x per day) --11 days now, no 123 error

7/2/23, 7/5/23, and 7/6/23

Suddenly seeing intermittent 121 errors - What the heck.....!?!

To recap so far I've replaced the main SWG cell unit, the power cord, and the back PCB. (I did not replace the Tri-Sensor Interface Module (since flow detection isn't an issue, there hasn't been any reason to)

Stumped here. 121 seems less problematic than 123 was but still doesn't make any sense why I'm getting that suddenly.

ANY IDEAS? (tried to call Jandy support today -- automated message of, "We're too busy, please try calling tomorrow".

Do I need to buy one of those Clamp Meters to be able to verify voltage and amperage during the error-free conditions versus when it's reporting the intermittent 121 error code?

Troubleshooting reference from install guide...

Thankfully my other SWG is still error free for now (was getting 171/189 codes on that cell (fixed by replacing the back PCB) and then later was getting 120 errors (fixed by 50/50 acid washing cell))