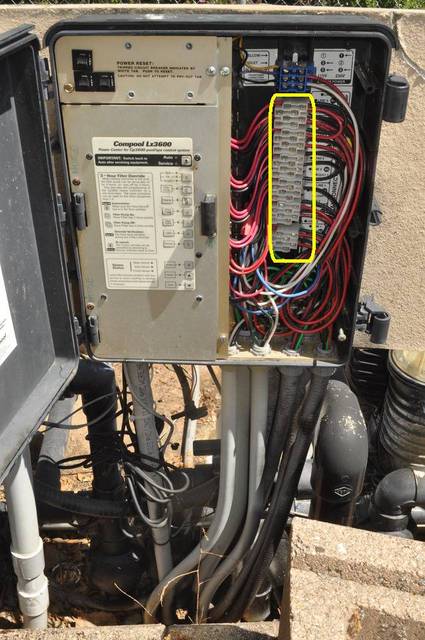

keene3b07 said:you should cut at the jandy valve and use a 2.5 in coupling though because it will give you a little more space.

Today I looked for a 2.5" coupling and the 2" boring tool; but couldn't find any at the box stores.

I also couldn't find any fitting that would either go OUTSIDE the Jandy valve; or inside.

I did pick up a few of all the standard 2 inch couplings and elbows and pipe though:

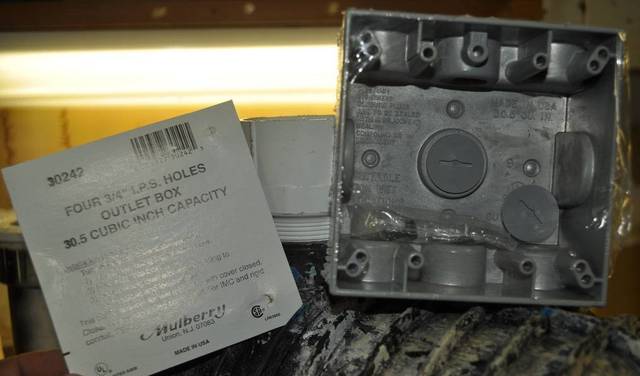

And, I bought this tool for cutting 2" PVC pipe:

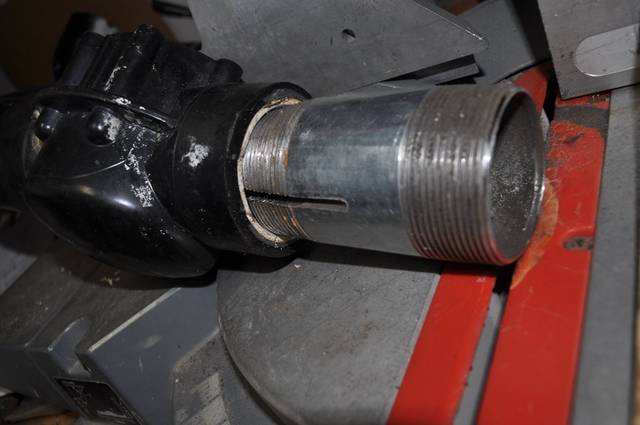

And, since I couldn't find the 2-inch boring tool at the box stores, I made this 2" pipe thread tap:

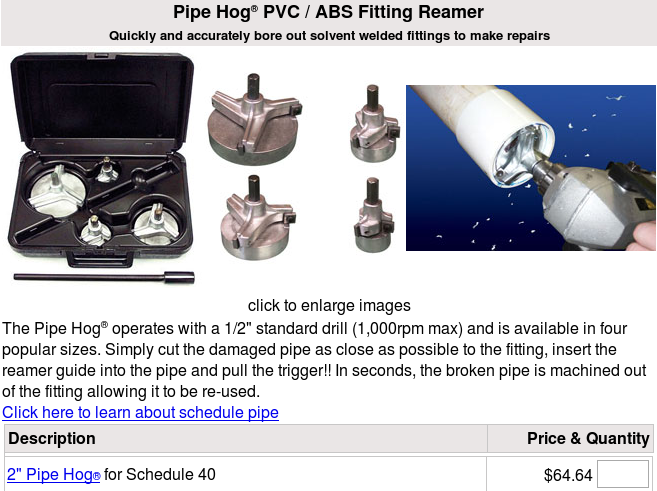

I plan on moving both pumps back, but first, to line up my ducks, I may need to buy this 2" boring tool:

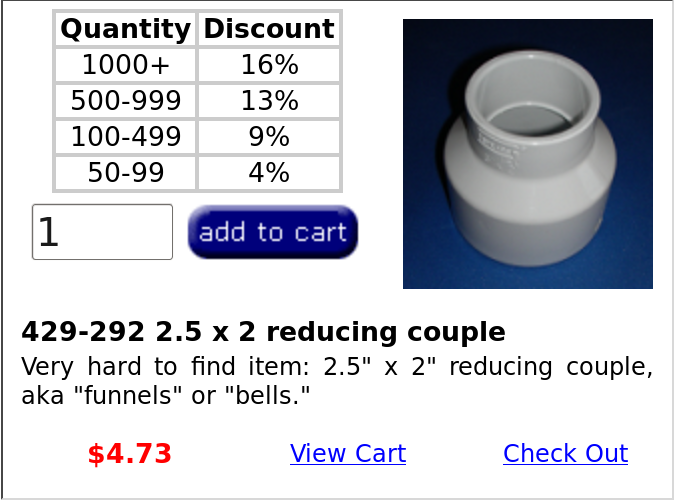

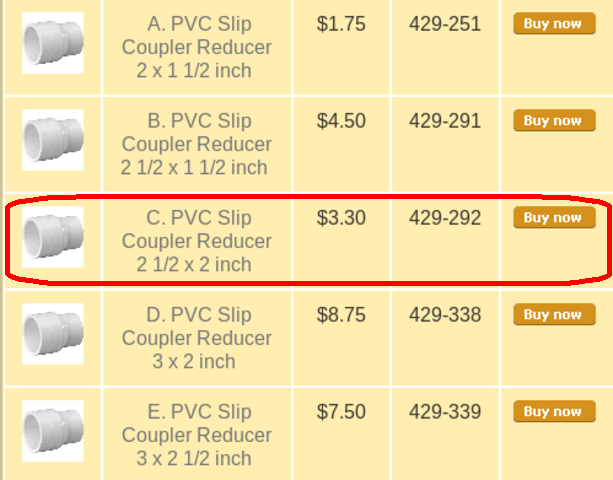

And/or this special fitting to go OVER the Jandy valve outlet:

Or, a special 2-inch fitting extender to go INSIDE the Jandy valve outlet (which already has a 2" pipe glued to it):