Hi TFP Family!

I'm banging my head against the wall lately trying to decide how I want to run my pool. Part of my confusion/indecision comes from having "professionals" initially configure my pool and then debate me when I talk to them about how I think the pool should be operated. These professionals tend to go with the tried & true, run it full blast, all the time, and I want to leverage the variable speed pump to bring costs lower. So to cut through some of the disinformation, I've got a couple questions I'm hoping this community can help me straighten out.

In my sig you can see I have the typical pool builder cadillac and the kitchen sink build. IFC, ic40, easytouch, etc. Part of this was because I didn't know much about anything and I listened to my PB. So here are a couple of my questions (keep in mind this is info gathering with a mind to how I want to run my pool, not necessarily that I plan on running it with certain things off or on, etc):

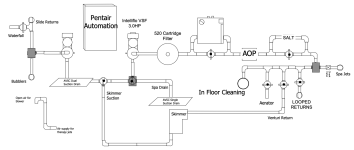

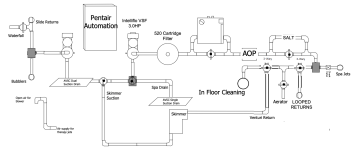

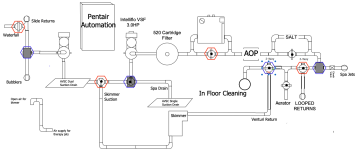

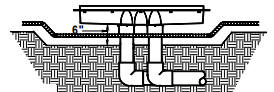

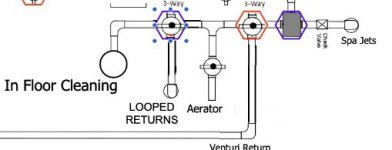

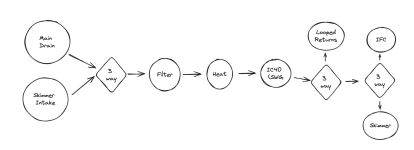

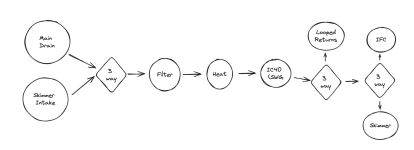

My plumbing stack (Simplified):

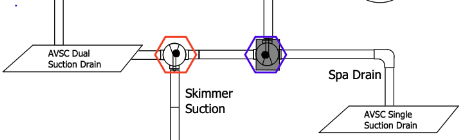

Venturi Skimmer: When I run the skimmer return only (the venturi lower port), my pump seems to have significant back pressure and reports only pushing 2gpm. Is this normal? If I crack the diverter even a little to the looped returns or the IFC the GPM jumps to 20+ at lower RPMs.

Looped Returns: If I intend to use the IFC, is there any reason to use them?

Skimmer intake: If I'm planning to use the venturi effect of the skimmer, is there a reason to use the skimmer intake at all?

A pool "professional" came out to help me with a couple things I wanted to do, because I had an idea of what I wanted, and he looked at my stack and said everything was all wrong. That I should just turn on the IFC and skimmer together, blast at high RPMs at all times to operate the IFC, turn off the skimmer intake and call it good.

My goal is to run the skimming function at low RPMs for long periods of the day, and then run IFC for targeted amounts of time on automed schedules. With easytouch I have 4 valves, though 3 of them are taken up for spa/spillway and booster pump activities. So I get one automated actuator to put on to put on the two 3 way diverters (without hacking in a 5th actuator... which I've gone down the road of a little bit and lets just say, it's not super straight forward but is still a possibility).

Since the skimmer return seems to only want to allow 2gpm through the pipe, it won't trigger the IC40 flow on its own, and I think it's caused some valve problems by having too much pressure build in the stack. This means that I can't turn off the looped returns altogether and just switch between the skimmer and IFC with automation. If I crack open the looped returns then the pump doesn't quite have enough GPM to make sure all the IFC heads pop up. One of the cycles pops 5 heads at one time which requires 45-50gpm through the IFC valve.

The way I see it I have 3 options:

Thank you!

I'm banging my head against the wall lately trying to decide how I want to run my pool. Part of my confusion/indecision comes from having "professionals" initially configure my pool and then debate me when I talk to them about how I think the pool should be operated. These professionals tend to go with the tried & true, run it full blast, all the time, and I want to leverage the variable speed pump to bring costs lower. So to cut through some of the disinformation, I've got a couple questions I'm hoping this community can help me straighten out.

In my sig you can see I have the typical pool builder cadillac and the kitchen sink build. IFC, ic40, easytouch, etc. Part of this was because I didn't know much about anything and I listened to my PB. So here are a couple of my questions (keep in mind this is info gathering with a mind to how I want to run my pool, not necessarily that I plan on running it with certain things off or on, etc):

My plumbing stack (Simplified):

Venturi Skimmer: When I run the skimmer return only (the venturi lower port), my pump seems to have significant back pressure and reports only pushing 2gpm. Is this normal? If I crack the diverter even a little to the looped returns or the IFC the GPM jumps to 20+ at lower RPMs.

Looped Returns: If I intend to use the IFC, is there any reason to use them?

Skimmer intake: If I'm planning to use the venturi effect of the skimmer, is there a reason to use the skimmer intake at all?

A pool "professional" came out to help me with a couple things I wanted to do, because I had an idea of what I wanted, and he looked at my stack and said everything was all wrong. That I should just turn on the IFC and skimmer together, blast at high RPMs at all times to operate the IFC, turn off the skimmer intake and call it good.

My goal is to run the skimming function at low RPMs for long periods of the day, and then run IFC for targeted amounts of time on automed schedules. With easytouch I have 4 valves, though 3 of them are taken up for spa/spillway and booster pump activities. So I get one automated actuator to put on to put on the two 3 way diverters (without hacking in a 5th actuator... which I've gone down the road of a little bit and lets just say, it's not super straight forward but is still a possibility).

Since the skimmer return seems to only want to allow 2gpm through the pipe, it won't trigger the IC40 flow on its own, and I think it's caused some valve problems by having too much pressure build in the stack. This means that I can't turn off the looped returns altogether and just switch between the skimmer and IFC with automation. If I crack open the looped returns then the pump doesn't quite have enough GPM to make sure all the IFC heads pop up. One of the cycles pops 5 heads at one time which requires 45-50gpm through the IFC valve.

The way I see it I have 3 options:

- Expanded automation: Figure out a reliable way to add a 5th valve actuator to my system (like I said, it is doable, but I've been partially down that road and it hasn't been a walk in the park). This would allow me to turn off the IFC, open the looped returns a little, and let the skimmer operate with the looped returns. (side note, I don't love where my wall returns are placed and feel like they impede cycling debris to the skimmer)

- Do some significant plumbing changes to essentially swap the IFC and Looped returns location. If they swap, then I could link the skimmer and pool returns together and whenever the IFC is running the skimmer/returns would be off and vice versa when I wanted to run skimmer/return action at lower RPMS

- Throw in the towel and run the IFC & skimmer together at all times and see if I can tune a lower RPM and ratio that still skims even though the IFC won't be running at optimal GPM to pop everything up.

Thank you!

Last edited: