Hello, first time posting.

We have a 68,000 gallon pool with the following equipment: BECSys3 chemical controller. Acid-Rite pH balancing system. Accu-Tab chlorination system. Avg temp 82F. Testing with ColorQ2x Pro7.

The chemical controller is currently set to bring the pH down to 7.5 (we’ve had it at 7.6 before) and keep the ORP at 815(FCL is usually around 1.6)

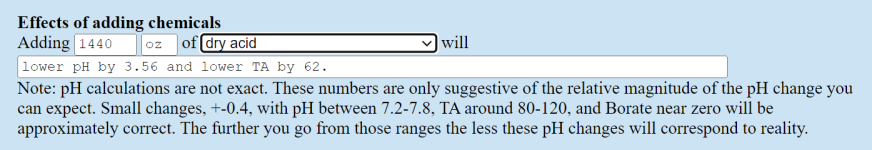

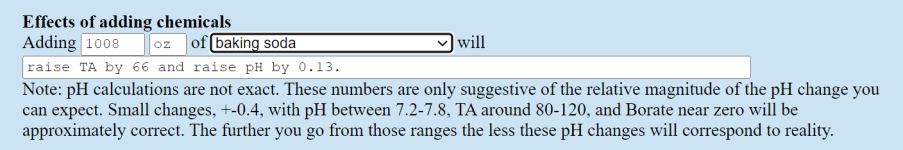

We are trying to find a balance to keep our alkalinity up, but also keep the pH at ideal levels as well. We are treating with Baking Soda to bring it up to 80 TA. We’ve been averaging 8-10lbs of baking soda added daily. This raises our pH up to around 7.8(on the BECSys3 sensor) after treating and our Acid-Rite system will run until it brings it back down to 7.5. Our Acid-Rite system is also eating a lot of the acid tablets and lately we go through a couple 45lb buckets a week.

I’ve read somewhere that some people let the pH go a bit higher like 7.7-7.8, but I’m not sure what the general consensus on that is. Is TA in the 60-80 range acceptable/reasonable?

Any input is greatly appreciated!

We have a 68,000 gallon pool with the following equipment: BECSys3 chemical controller. Acid-Rite pH balancing system. Accu-Tab chlorination system. Avg temp 82F. Testing with ColorQ2x Pro7.

The chemical controller is currently set to bring the pH down to 7.5 (we’ve had it at 7.6 before) and keep the ORP at 815(FCL is usually around 1.6)

We are trying to find a balance to keep our alkalinity up, but also keep the pH at ideal levels as well. We are treating with Baking Soda to bring it up to 80 TA. We’ve been averaging 8-10lbs of baking soda added daily. This raises our pH up to around 7.8(on the BECSys3 sensor) after treating and our Acid-Rite system will run until it brings it back down to 7.5. Our Acid-Rite system is also eating a lot of the acid tablets and lately we go through a couple 45lb buckets a week.

I’ve read somewhere that some people let the pH go a bit higher like 7.7-7.8, but I’m not sure what the general consensus on that is. Is TA in the 60-80 range acceptable/reasonable?

Any input is greatly appreciated!