Hi everyone,

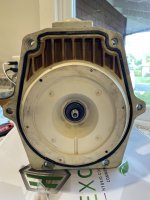

I just replaced the shaft seal of a leaking Pentair Intelliflo 4 160 variable speed pump.

When I put it back together, the pump worked better than before (no little bubbles in the pump lid, still a couple large bubbles). However, there was a consistent drip of water under the motor housing at the gap between motor and seal plate.

I realized after that I didn’t replace the washer of the retainer bolt for the impeller. This part:

www.poolweb.com

www.poolweb.com

Could this be the cause of the leak?

I’m pretty sure I put in the shaft seal correctly on both the seal plate and impeller (US seal PS1000).

I’m looking for some reassurance before I take apart the pump again. Not sure if I should stem my losses and get a new pump at this point.

I just replaced the shaft seal of a leaking Pentair Intelliflo 4 160 variable speed pump.

When I put it back together, the pump worked better than before (no little bubbles in the pump lid, still a couple large bubbles). However, there was a consistent drip of water under the motor housing at the gap between motor and seal plate.

I realized after that I didn’t replace the washer of the retainer bolt for the impeller. This part:

075713 - Pump Impeller Rubber Washer - Pentair

This is a Pump Impeller Screw Rubber Washer for various Pentair pool pumps. It is used on the Pentair WhisperFlo pumps, the IntelliFlo pumps, IntelliPro, and the C-Series pool pumps.

www.poolweb.com

www.poolweb.com

Could this be the cause of the leak?

I’m pretty sure I put in the shaft seal correctly on both the seal plate and impeller (US seal PS1000).

I’m looking for some reassurance before I take apart the pump again. Not sure if I should stem my losses and get a new pump at this point.