- Jul 17, 2019

- 3,714

- Pool Size

- 13000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

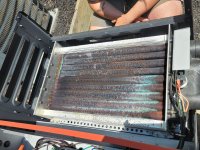

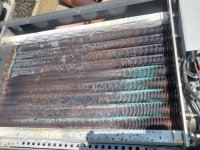

And tell them no more freakin tabs in the skimmer as they can lead to an early death of your new heater. Or better yet, fire them and take care of your pool yourself (I know a website that can help...)At this point, I think the manifold is toast. I will have the pool company check the pressure of that.