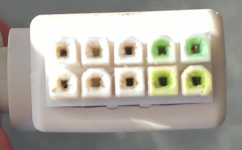

I replaced my SWG a couple years ago due what you see in the picture (burnt/corroded plug). I also had to get the connector replaced on the board. All is working well but when I removed my SWG for winter in December, put the old one in place but not plugged in, I noticed the plug on my newer unit is showing signs of corrosion on the same area (see pic) as the old unit. Any suggestions on how to address this? Would putting a good coating of GB's Ox-Gard Anti-Oxidant Compound on the connector and plug when I reinstall it? Appreciate the help.

Hayward T-Cell - Plug Corrosion

- Thread starter bagman52

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 52,671

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Common problem

Keep your salt level 2800-3000 ppm so your amps stay as low as possible. High water temperature also causes high amps

Amps around 6.5 are better then into the 7s or higher.

Keep your salt level 2800-3000 ppm so your amps stay as low as possible. High water temperature also causes high amps

Amps around 6.5 are better then into the 7s or higher.

No, no chemicals stored anywhere nearby.Looks like chemical exposure.

Do you store acid or tabs in the same room?

Thanks for the advice on the salt level. It has been above 3000 for sure but not currently. Being in N. Texas warm pool water comes with the territory. Would the anti-corrosive be helpfule?Common problem

Keep your salt level 2800-3000 ppm so your amps stay as low as possible. High water temperature also causes high amps

Amps around 6.5 are better then into the 7s or higher.

The green points to some sort of corrosion that is way beyond normal.No, no chemicals stored anywhere nearby.

Maybe it is getting wet or exposed to chemicals or maybe an electrical problem.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.