I've spent way too much time trying to figure this out and could use some help.

Equipment

After changing all the seals (with Jack's 327 lube) and taking the pump apart over and over, there is a persistent leak from the bottom (housing gasket area) and surging (air noise).

On low speed, pump does not stay primed.

Diagnostics

Any advice appreciated.

Equipment

- 800 gallon in-ground hot tub

- Hayward Super Pump (SP2615X202S), unknown age. 2" plumbing reduced to 1.5" for filter and heater.

- No unions, so can't remove housing easily (and no space to add unions).

After changing all the seals (with Jack's 327 lube) and taking the pump apart over and over, there is a persistent leak from the bottom (housing gasket area) and surging (air noise).

On low speed, pump does not stay primed.

Diagnostics

- No obvious cracks in seal plate, impeller, or housing. Housing stays filled when pump is off.

- No water behind seal plate (shaft seal is probably fine)

- Housing gasket looks good

- Strainer gasket and drain plugs do not seem to leak under pressure.

- Pressure testing different sections using an air compressor:

- Returns lines hold pressure, no leaks (tested from pump housing inlet)

- Pump leaks water at 10+ psi, and air at 3+ psi, audibly, from that bottom area.

- Tried using dye (turmeric), looks like color stays on the housing side of the seal plate, but still can't tell where it leaks.

- Tried polishing the seal plate (1500 grit sandpaper), no change.

- Ground down the housing nuts as they protruded about 0.5mm, no change.

Any advice appreciated.

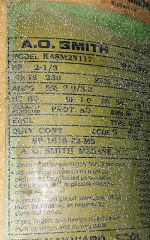

Even though you aren't seeing anything with the naked eye, it sure seems like something is off near that bottom seal plate area. Can't help but wonder if that area didn't warp or something at some point in the past? If you post a pic of the motor ID label we can tell you how old the motor is. Let's see if

Even though you aren't seeing anything with the naked eye, it sure seems like something is off near that bottom seal plate area. Can't help but wonder if that area didn't warp or something at some point in the past? If you post a pic of the motor ID label we can tell you how old the motor is. Let's see if

Your call on the fix really. A housing repair is a Hail-Mary fix, but might work, or at least buy you some time. As far as replacements, it may be just as cost effective to get a new pump rather than purchasing a new wet end with seals and everything. As luck might have it, you could repair that wet end only to have the old motor go bad on you.

Your call on the fix really. A housing repair is a Hail-Mary fix, but might work, or at least buy you some time. As far as replacements, it may be just as cost effective to get a new pump rather than purchasing a new wet end with seals and everything. As luck might have it, you could repair that wet end only to have the old motor go bad on you.