No idea what he was measuring.... kind of above my pay grade to know that stuff.Did the person measure the power or the power factor?

This is why I said that most people do not understand how to properly test 3 phase motors.

Filter capacity?

- Thread starter JPMorgan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If we are now getting 170 gpm (assuming the flow meter with that reading is accurate), why should we continue to pursue this? (If) we are getting the flow rate required.... why assume something is off with the electrical power that requires further investigation? If the flow rate was at 170 gpm to start, we would have never questioned any of that. We started investigating because the flow rate was around 100 gpm and now we are at 170 gpm. Isn't that sufficient to let it go at this point?

I'll check for this....The pump should have an arrow on the front that shows the direction of rotation as shown in this picture.

View attachment 528536

On another matter....

Our pool company includes this in their annual service contract:

Clean Pool Heater (per manufacturer’s recommendations) $ 500.00 for 125 – 405BTU

We have 2 heaters. One was replaced this summer and the other was replaced last December. So $1,000 to clean both.

Is it a good idea to have this service done every year.... or could it be done less often? Is this service really needed for the heater that we just replaced? Is the price reasonable? I believe we can decline the service if we choose.

Our pool company includes this in their annual service contract:

Clean Pool Heater (per manufacturer’s recommendations) $ 500.00 for 125 – 405BTU

We have 2 heaters. One was replaced this summer and the other was replaced last December. So $1,000 to clean both.

Is it a good idea to have this service done every year.... or could it be done less often? Is this service really needed for the heater that we just replaced? Is the price reasonable? I believe we can decline the service if we choose.

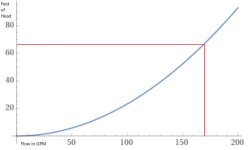

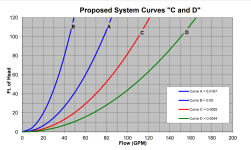

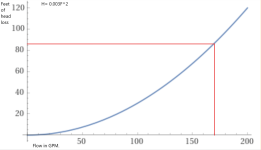

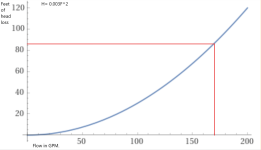

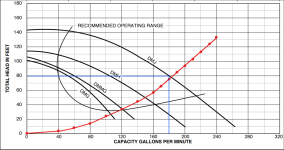

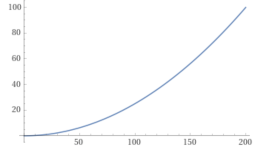

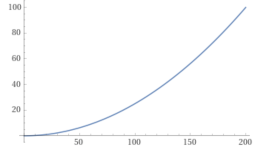

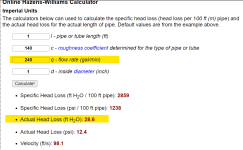

If we use 67 feet as the head loss and 170 GPM as the flow, then we can approximate the system curve as H = 0.00232F^2.

If we use 87 as the head loss and 170 as the flow, then the system curve can be approximated as H = 0.003F^2.

The new numbers are coming out closer to the expected values.

You can check the power if you want and it will give us more information to use to evaluate the system if you feel like it is necessary.

It would have been nice if the person checking the power actually knew what they were doing and could give us the accurate information.

If they do not know what they are doing, they are just wasting their time and your time.

Only you can decide when you are happy with the system performance and if any further tests are necessary.

I am not onsite to see things in person, so all I have is the data provided and the calculations that can be done.

Some data provided will be inaccurate, so we have to be able to figure out which readings are probably correct and which ones are probably incorrect.

You have two values for flow, which means that we do not know for sure which number is correct.

_______________________________________________

www.wolframalpha.com

__________________________________________________

www.wolframalpha.com

__________________________________________________

_____________________________________________

_______________________________________________

________________________________________________

___________________________________________________________

_____________________________________________________________

If we use 87 as the head loss and 170 as the flow, then the system curve can be approximated as H = 0.003F^2.

The new numbers are coming out closer to the expected values.

You can check the power if you want and it will give us more information to use to evaluate the system if you feel like it is necessary.

It would have been nice if the person checking the power actually knew what they were doing and could give us the accurate information.

If they do not know what they are doing, they are just wasting their time and your time.

Only you can decide when you are happy with the system performance and if any further tests are necessary.

I am not onsite to see things in person, so all I have is the data provided and the calculations that can be done.

Some data provided will be inaccurate, so we have to be able to figure out which readings are probably correct and which ones are probably incorrect.

You have two values for flow, which means that we do not know for sure which number is correct.

_______________________________________________

y = 0.00232x^2, x from 0 to 200 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

_____________________________________________

_______________________________________________

________________________________________________

___________________________________________________________

_____________________________________________________________

If the vacuum gauge is about 3 feet higher than the pool water surface, then the numbers look good.

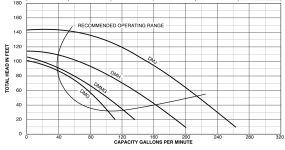

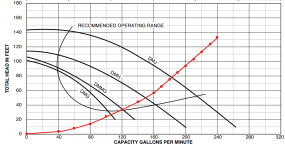

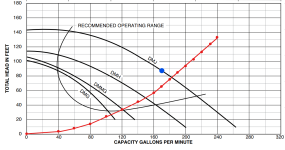

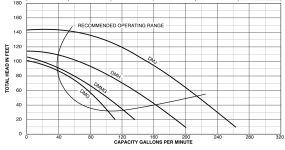

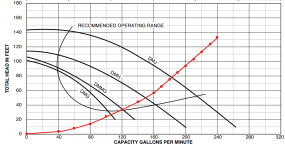

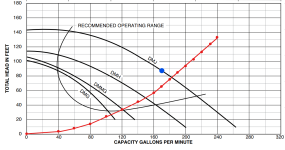

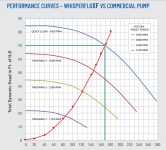

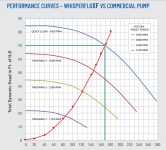

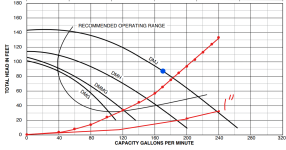

If we use the system curve and the pump curve, the operating point is about 80 feet of head at about 180 GPM.

We can estimate the suction at about 11 feet and the return at about 69 feet, which is about 30 psi.

The pump might be underperforming somewhat, but it is difficult to know for sure.

The pump is estimated to be operating at about 94% of expected capacity.

A power reading would be helpful but probably not necessary if it is going to be a big deal to get it done.

The current imbalance might indicate a failing motor or maybe an issue with the power supply or maybe the person just did not know what they were doing.

They should have had three measurements for current and six for voltage.

You have 3 legs: A, B and C.

Measure the current on each leg.

Measure the voltage from A to B, A to C, B to C, A to neutral or ground, B to neutral or ground and C to neutral or ground.

Measure power and power factor.

You can also check the resistance of the windings and for continuity to ground using a regular multimeter or a "Megger" tester.

Can you show the motor starter switches and breakers?

If we use the system curve and the pump curve, the operating point is about 80 feet of head at about 180 GPM.

We can estimate the suction at about 11 feet and the return at about 69 feet, which is about 30 psi.

The pump might be underperforming somewhat, but it is difficult to know for sure.

The pump is estimated to be operating at about 94% of expected capacity.

A power reading would be helpful but probably not necessary if it is going to be a big deal to get it done.

The current imbalance might indicate a failing motor or maybe an issue with the power supply or maybe the person just did not know what they were doing.

They should have had three measurements for current and six for voltage.

You have 3 legs: A, B and C.

Measure the current on each leg.

Measure the voltage from A to B, A to C, B to C, A to neutral or ground, B to neutral or ground and C to neutral or ground.

Measure power and power factor.

You can also check the resistance of the windings and for continuity to ground using a regular multimeter or a "Megger" tester.

Can you show the motor starter switches and breakers?

Last edited:

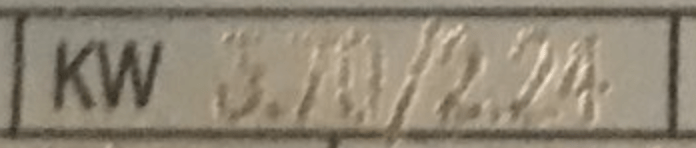

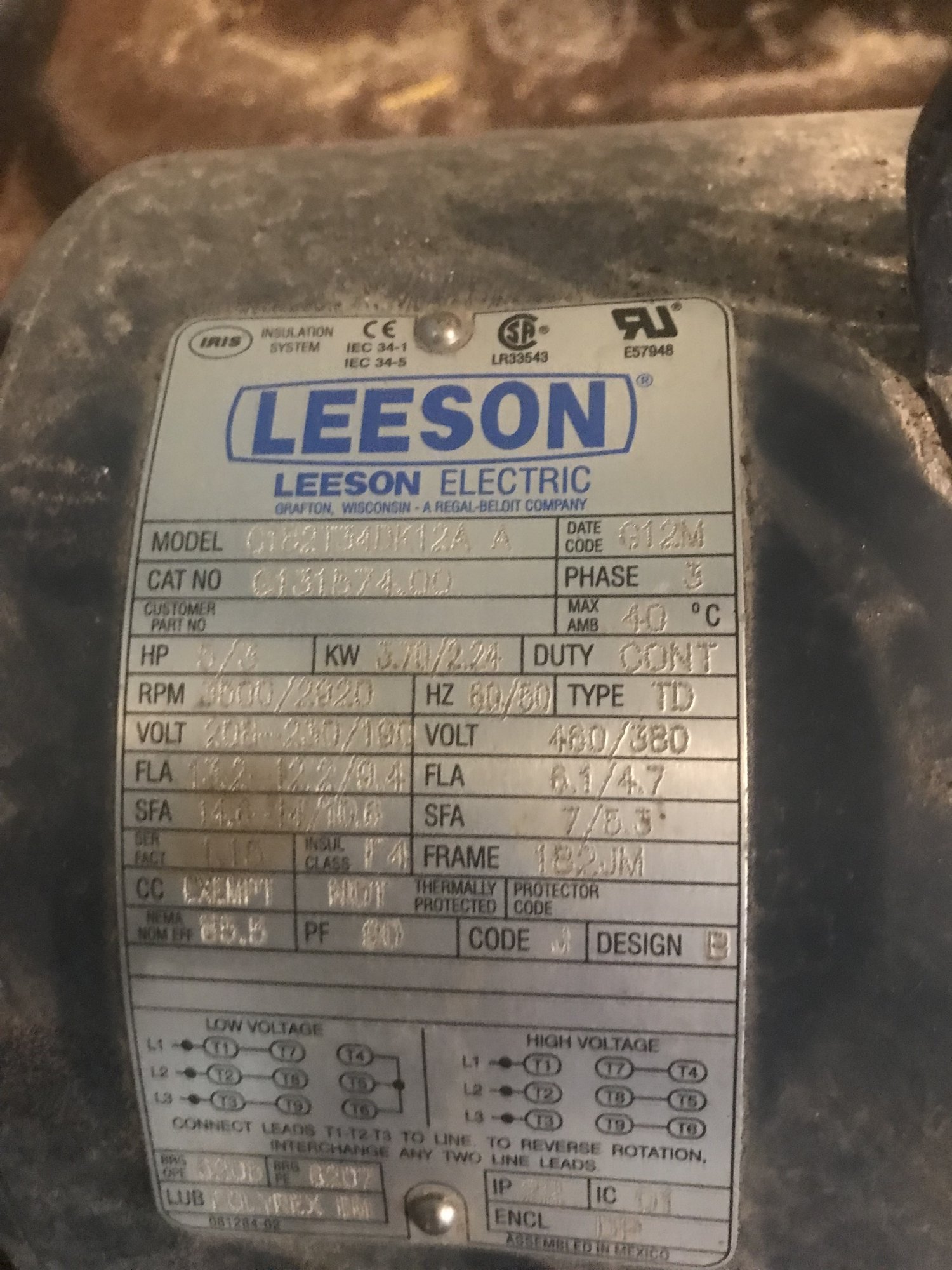

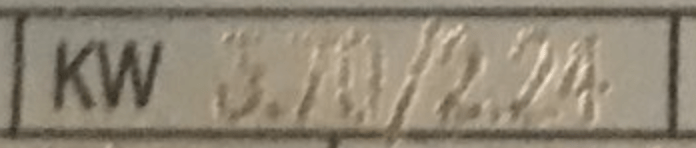

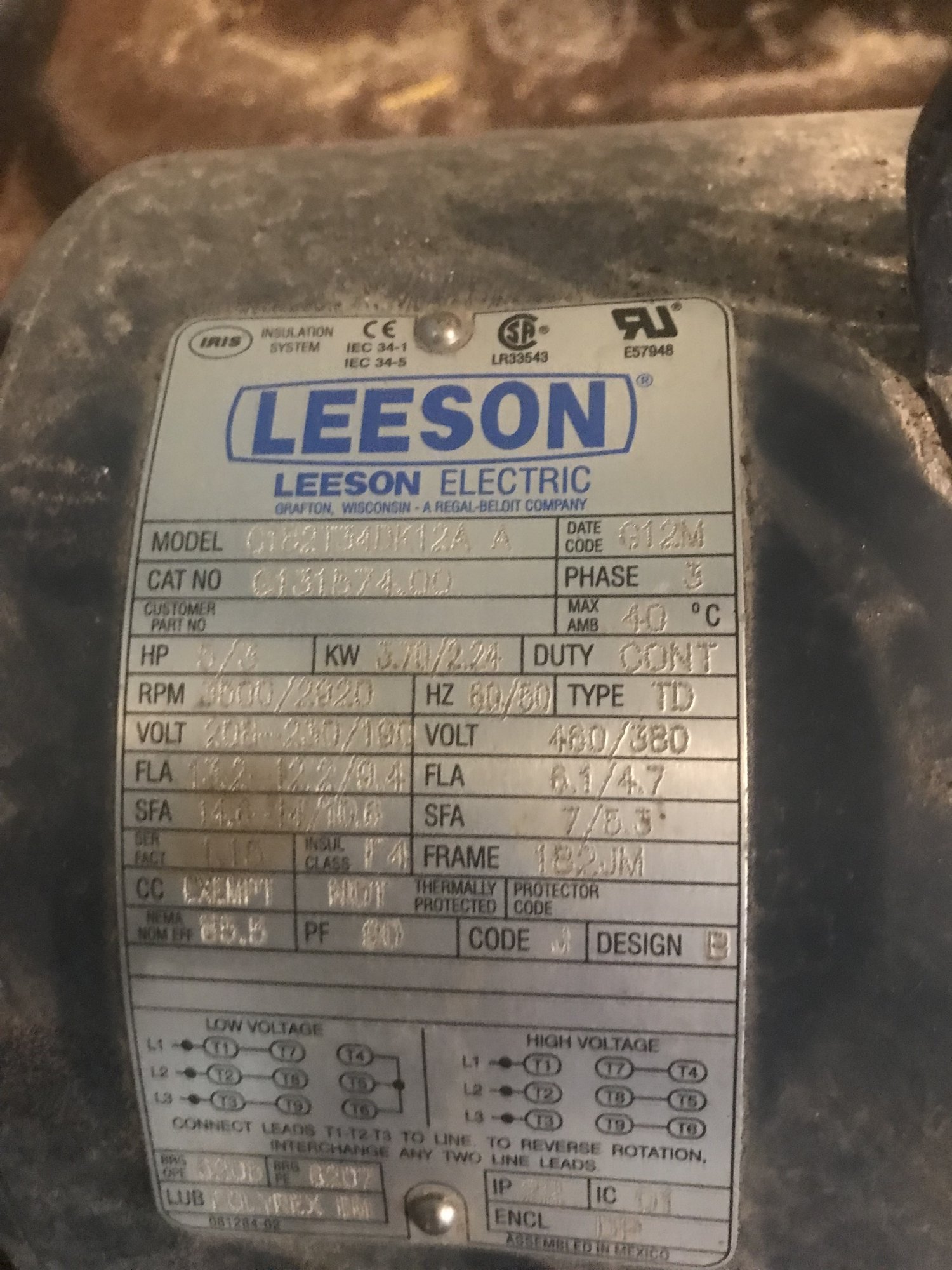

The power, voltage, current, and power factor are listed on the motor label.

The power is listed as 3.7 kw or 3,700 watts.

If the measurements are consistent with the label, then that is a good indication that the pump is operating as expected.

Is the numbers are significantly off, then that will indicate that the pump is not operating correctly.

If you feel confident about the flow reading at 170 GPM and the pressure readings, then the pump seems pretty close to expected performance.

If you feel like the flow is not accurate, you can consider doing more to investigate to diagnose the problem or if there is a problem.

Did they test the voltage?

If yes, what was the voltage?

Did they have an opinion or analysis of the current imbalance?

The power is listed as 3.7 kw or 3,700 watts.

If the measurements are consistent with the label, then that is a good indication that the pump is operating as expected.

Is the numbers are significantly off, then that will indicate that the pump is not operating correctly.

If you feel confident about the flow reading at 170 GPM and the pressure readings, then the pump seems pretty close to expected performance.

If you feel like the flow is not accurate, you can consider doing more to investigate to diagnose the problem or if there is a problem.

Can you ask them to provide a written description of exactly what they did with a diagram to explain what was tested?The technician that was here today said he is getting 13.9 amps on one side and 15.4 on the other.

Did they test the voltage?

If yes, what was the voltage?

Did they have an opinion or analysis of the current imbalance?

- Jul 21, 2013

- 52,891

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

On another matter....

Our pool company includes this in their annual service contract:

Clean Pool Heater (per manufacturer’s recommendations) $ 500.00 for 125 – 405BTU

We have 2 heaters. One was replaced this summer and the other was replaced last December. So $1,000 to clean both.

Is it a good idea to have this service done every year.... or could it be done less often? Is this service really needed for the heater that we just replaced? Is the price reasonable? I believe we can decline the service if we choose.

Let's ask @swamprat69

I think natural draft Raypak heaters should be cleaned annually. But I would clean and checkout the heaters at pool opening, not closing, to clean out the burners of any spiders that may get into it during the winter.

swamprat69

Well-known member

If the $500 cost to clean each heater is in addition to the service contract cost it is laughable. Most HVAC clean and check costs are normally between $100-120 with many companies offering a clean and check at $70-80 to get their foot in the door. The manufacturer's recommendation of annual cleaning is more of a liability issue and may only be needed when a heater is installed in a location where it gets dirty very quickly or is highly attractive to spiders. Although an annual clean and check can catch some small problems before they become a larger problem. I do check both of my AC condenser units annually and this year found both had dual ( compressor/fan ) run capacitors below the + or - 10% of nameplate rating. This would have put a strain on the compressor, fan motor and contactor, so they both got replaced. Many times other than motors heater problems can be avoided by simple observations ( is the flame pattern correct [ 2 tone blue with no orange/yellow ], although you can get some orange flickering above a good flame on initial season startup due to entrained dust from the heater sitting idle and collecting dust ). On a natural draft heater other than flame observation, I would also check the method of lighting the burners ( intermittent pilot, direct spark ignition [flame sensor, electrode] etc.) to assure that the pilot flame pattern is good and the method of proving the flame is good ( is the pilot assembly clean and does it have a good path through all metal to metal connections back to heater ground ). It never hurts to do an annual clean and check though ( hopefully at a reasonable price !).

The technician was here mainly to install gauges that were missing on our system and evaluate the flow meter(s) and look for any other issues that may be affecting flow. He only gave me 2 numbers for amperage.... not sure why it wasn't 3 numbers. Nothing about voltage. I think the next step would be to have a competent electrician evaluate and answer the questions you are posing. If we can get that done for a standard service call, it might be worth it. I'm still waiting to hear back from the electrician I contacted. If he doesn't think he can evaluate and answer the questions, then I'll look for another resource. I have all your questions that I will be sure get answered by whoever comes out.It would have been nice if the person checking the power actually knew what they were doing and could give us the accurate information.

If they do not know what they are doing, they are just wasting their time and your time.

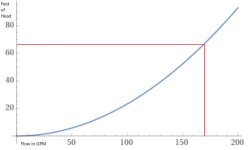

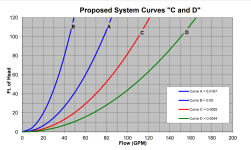

If we use H = 0.0025F^2 for the system curvem then the system curve on the 5 HP WhisperFloXF Commercial Pump would hit the required flow rate (167 GPM) at full speed (3,450 RPM) at about 70 feet of head.

In my opinion, 167 GPM is excessive for that pool.

I would think that you could easily go down to 2,500 RPM, which would be about 120 GPM.

The required flow rate might be just for when the pool is in use, which would mean that you could run slower during times when the pool is not open for swimmers.

If you decide to replace the pump in the future, it might be worthwhile going to a variable speed pump.

3.7 kw at $0.20 per kwh is $0.74 per hour, $17.76 per day, $124.32 per week, $538.72 per month and $6,464.64 per year (24/7/365).

At 2,500 RPM, the power should be about 1.4 kw or 1,400 watts.

1.4 kw at $0.20 per kwh is $0.28 per hour, $6.72 per day, $47.04 per week, $204.4 per month and $2,452.80 per year (24/7/365).

_____________________________________________

_______________________________________________

www.wolframalpha.com

www.wolframalpha.com

In my opinion, 167 GPM is excessive for that pool.

I would think that you could easily go down to 2,500 RPM, which would be about 120 GPM.

The required flow rate might be just for when the pool is in use, which would mean that you could run slower during times when the pool is not open for swimmers.

If you decide to replace the pump in the future, it might be worthwhile going to a variable speed pump.

3.7 kw at $0.20 per kwh is $0.74 per hour, $17.76 per day, $124.32 per week, $538.72 per month and $6,464.64 per year (24/7/365).

At 2,500 RPM, the power should be about 1.4 kw or 1,400 watts.

1.4 kw at $0.20 per kwh is $0.28 per hour, $6.72 per day, $47.04 per week, $204.4 per month and $2,452.80 per year (24/7/365).

_____________________________________________

_______________________________________________

y = 0.0025x^2, x from 0 to 200 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

I would say it's close to that.... maybe more like 2 feet. I could try to get an accurate measurement.If the vacuum gauge is about 3 feet higher than the pool water surface, then the numbers look good.

We have a differential between 2 flow meters... one reading 160-170 and the other reading 130-140, so about 30 gpm difference. My understanding is that the engineer at the pool company is going to determine if 170 gpm flow rate through a section of the return line that has 1" pipe is attainable. If not, then the diagnosis is that the gauge is off and we have to replace it and see what flow rate we get with a new one. Since we are getting 130-140 gpm from the other flow meter, I would assume that one is accurate (if it's determined the flow meter with the higher reading is off). In that case, the question remains.... why aren't we getting the flow that the pump is capable of.... do we replace the section of 1" pipe (recommended by technician).... or focus on the operation of the motor.... or both?If you feel confident about the flow reading at 170 GPM and the pressure readings, then the pump seems pretty close to expected performance.

If you feel like the flow is not accurate, you can consider doing more to investigate to diagnose the problem or if there is a problem.

Are you saying that the entire flow is being put through a 1" PVC pipe?

If yes, then this needs to be fixed as that is way too small for the flow.

I really do not think that that is something that anyone would do.

Are you sure?

How long is the 1" pipe?

If yes, then this needs to be fixed as that is way too small for the flow.

I really do not think that that is something that anyone would do.

Are you sure?

How long is the 1" pipe?

I have read the Illinois regulations which require flow rates that turn over the pool every 6 hours, so (60,000 gallons / 360 minutes = 167 gpm. My undertsanding is that it must run at that speed always.... not just part of the day. Several pool guys have told me that (when I asked about running at lower speeds). So.... 167 gpm is what I was trying to achieve when I became aware of this rule. We were at about 90-100 gpm at that time. Now (it seems) it is running at about 130-140 gpm (after pump service and a few other tweaks. Questions now is.... is that good enough? Do I leave it alone or continue to investigate.... and at what cost? I have been here 2 years and never seen an inspector. When I ask the question "Would an inspector shut the pool down if he sees a 130 gpm flow rate", the answer is "Depends on the inspector."In my opinion, 167 GPM is excessive for that pool.

I would think that you could easily go down to 2,500 RPM, which would be about 120 GPM.

The required flow rate might be just for when the pool is in use, which would mean that you could run slower during times when the pool is not open for swimmers.

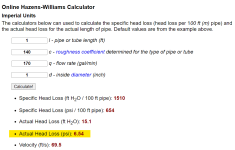

It can be done, but it generates a lot of head loss.My understanding is that the engineer at the pool company is going to determine if 170 gpm flow rate through a section of the return line that has 1" pipe is attainable.

It creates about 6.54 psi per foot of pipe.

So, 10 feet of pipe would create about 65.4 psi of pressure.

If we have 1 foot of 1" PVC pipe, then the maximum flow that the pump could put through the pipe would be about 240 GPM at about 30 feet of head loss.

Last edited:

Excellent information! I am trying to track what it costs us per year to operate our pool and have a pretty good handle on most expenses..... except the utility costs..... electricity to run the pump and gas to run the heater. I googled electricity rates in Illinois and found this:If you decide to replace the pump in the future, it might be worthwhile going to a variable speed pump.

3.7 kw at $0.20 per kwh is $0.74 per hour, $17.76 per day, $124.32 per week, $538.72 per month and $6,464.64 per year (24/7/365).

At 2,500 RPM, the power should be about 1.4 kw or 1,400 watts.

1.4 kw at $0.20 per kwh is $0.28 per hour, $6.72 per day, $47.04 per week, $204.4 per month and $2,452.80 per year (24/7/365).

Combining the electric supply charge and the transmission services charge, the ComEd Price to Compare effective September 1, 2023 is 6.799 cents per kWh. These Prices to Compare do not include the Purchased Electricity Adjustment, which is a component of the ComEd Electric Supply Charges.

Electricity (kWh) Prices by State

| STATE | Sep 2023 | CHANGE (%) |

|---|---|---|

| Illinois | 12.56¢ / kWh | -3.011 % |

Do I add the 2 numbers together or is $12.56c/ kWh the rate I should use???

Using .1256 I get this:

3.7 kWh x .1256 = .4647 per hour x 24 = $11.15 per day x 112 days (16 week season) = $1,250 (approximate cost for the season. Does that sounds about right?

Last edited:

The regulations usually require that the velocity for suction remain below 6 feet per second and below 8 feet per second for the returns.

I really doubt that anyone would try to put 170 GPM through a 1" PVC pipe.

You want to keep the water velocity below 6 ft/sec on the suction and below 8 ft/sec on the pressure side of the pump.

I really doubt that anyone would try to put 170 GPM through a 1" PVC pipe.

You want to keep the water velocity below 6 ft/sec on the suction and below 8 ft/sec on the pressure side of the pump.

| Pipe Size | 6 ft/sec | 8 ft/sec |

|---|---|---|

| 1.5" | 38 GPM | 51 GPM |

| 2" | 63 GPM | 84 GPM |

| 2.5 | 90 GPM | 119 GPM |

| 3.0" | 138 GPM | 184 GPM |

| 4.0" | 235 GPM | 312 GPM |

- Jul 21, 2013

- 52,891

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Excellent information! I am trying to track what it costs us per year to operate our pool and have a pretty good handle on most expenses..... except the utility costs..... electricity to run the pump and gas to run the heater. I googled electricity rates in Illinois and found this:

Combining the electric supply charge and the transmission services charge, the ComEd Price to Compare effective September 1, 2023 is 6.799 cents per kWh. These Prices to Compare do not include the Purchased Electricity Adjustment, which is a component of the ComEd Electric Supply Charges.

Request a copy of the places monthly electrical bill. That will show you the cost/kwh and all other surcharges per kwh.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.