The power wires make sense because they carry up to 8 amps, but the wires for the thermistor carry almost no current, so it just seems unnecessary.

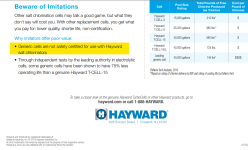

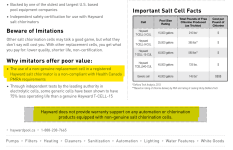

I still think that it has something to do with identifying genuine cells by providing some sort of id tag that the system can use to read the cell.

I still think that it has something to do with identifying genuine cells by providing some sort of id tag that the system can use to read the cell.