Hello,

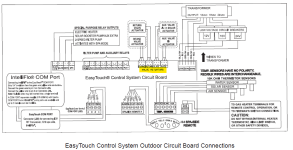

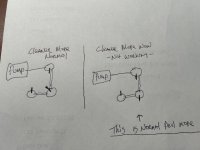

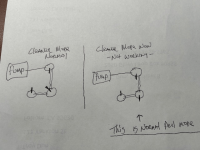

I have a Pentair auto valve that does not move on auto...the motor rpm's ramp up, but no movement on valve. It will move when I manually flip the little toggle switch...This is the valve for the cleaner.

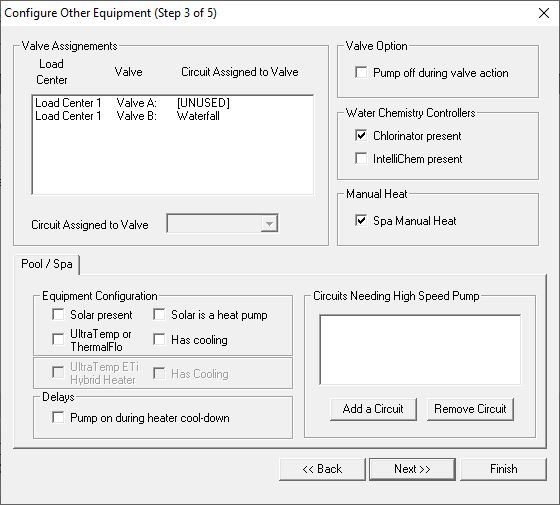

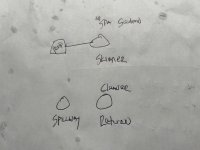

I also noticed when the Spillway is on, the cleaner valve opens, which normally doesnt...so 2 issues....

Does this sound like the control board problem....and can I repair the board, or do I just need to replace. This board was replaced 1 1/2 years ago with a air/water temp issue...After I replaced this board, it has been working perfectly until this issue..

Thanks!

Troy

I have a Pentair auto valve that does not move on auto...the motor rpm's ramp up, but no movement on valve. It will move when I manually flip the little toggle switch...This is the valve for the cleaner.

I also noticed when the Spillway is on, the cleaner valve opens, which normally doesnt...so 2 issues....

Does this sound like the control board problem....and can I repair the board, or do I just need to replace. This board was replaced 1 1/2 years ago with a air/water temp issue...After I replaced this board, it has been working perfectly until this issue..

Thanks!

Troy