MAPR-Austin

In The Industry

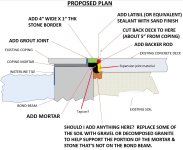

Thank you. Yes, I was wondering about a narrower strip of stone too. Although I didn't measure it everywhere, the Bond Beam was about 12-1/2" wide, but it could be more, could be less-- I don't believe any great care was taken to have a consistent shell thickenss beyond whatever minimum they felt they needed. The coping hangs over into the pool by about 1-1/4 - 1-1/2, so there is about 2" wide of leftover of Bond beam to "grab" onto by any mortar bed that supports the stone... could be as much as 2-1/2". To get the min 1/2" clearance from the bond beam to the concrete slab, the saw cut will need to be at least 3"... So in theory, I could use a smaller 2" wide strip to fill a 3" cut... the 2" strip will be supported by at least 1-1/2" of Bond Beam. I spoke to a friend that can get me the stone and he said that "chopping" a 4" wide stone strip was tricky enough, so I doubt chopping 2" wide strips of stone ( I think "Silver Mist" would be the stone) is possible. They'd have to be sawcut. And the other issue with a narrower cut in the concrete is if they cut through a bond wire, IDK if they'd be able to find (or have room to find) any rebar to grab onto to re-establish the grounding... I wonder if we could just drive a grounding rod into the soil and attach to that instead. But even that won't be easy-- once you get down about 5', it's solid Limestone, so any rod will need to be driven at an angle, and in a very narrow cavity. There's still a labor shortage in my area so although I may contract with a remodeler that knows his stuff, I may wind up with a day-laborer that I wont be able to communicate with and may not understand the delicate nature.

And thanks for the tip on the expansion material "strip". That works better than the backer rod?? I looked it up..... I was wondering how one would keep the mortar from the stone install away from the deck slab & maintian a positive 1/2" min joint. -- an adhesive foam strip would do it. And that strip stays in permanently?

Understood on the stone, I figured it would have to be saw cut. Your concern on the bonding wire makes sense.

Yes, the lower part of the strip stays in place. You'll want some construction adhesive to stick it to the concrete, it is not self adhering.

Maybe pop some tapcons into the pool shell and hope that serves as some reinforcement to hold the mortar in place? You could fill the area you have marked on the drawing with grout to give it a bit more body. I tried to illustrate the idea on your drawing.

I don't think a ground rod would suffice - you really don't want to cut corners on bonding. Low risk of a problem, but the consequences of that problem could be catastrophic or deadly. You could have a bonding test done before the pour to confirm the continuity of the bonding grid.