I was hurt on the job today and I'm not sure what to do about it.

I was dispatched to a clogged line call and sent with an air compressor. The company I work for taught me their method of clearing lines, whereas other companies and professionals have shown me others ways.

Their way is to plug up the impeller port inside the pump, attach a brass fitting to the bottom port where a Vacuum gauge could be placed. Then blow out the line with compressed air.

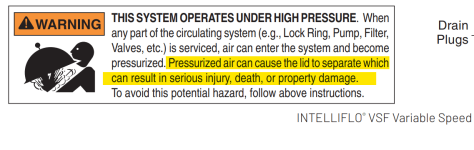

Today, the pump lid blew off and hit me in the face. My nose is bleeding, damaged and my face hurts and swelling.

my questions is this: are those ports designed for air compressors and clogged line work as per the manufacturers design and recommendation or is this a method that was created by professionals as a way to make a clog go away? How much PSI can a housing take? Lid? Is it 40psi like PVC?

I was taught to stuff pipes and blast with Oxygen or Nitrogen, or cut pvc, cap it, drill a hole and tap it for a brass fitting for a compressor and blow it out.

Any info is appreciated.

I was dispatched to a clogged line call and sent with an air compressor. The company I work for taught me their method of clearing lines, whereas other companies and professionals have shown me others ways.

Their way is to plug up the impeller port inside the pump, attach a brass fitting to the bottom port where a Vacuum gauge could be placed. Then blow out the line with compressed air.

Today, the pump lid blew off and hit me in the face. My nose is bleeding, damaged and my face hurts and swelling.

my questions is this: are those ports designed for air compressors and clogged line work as per the manufacturers design and recommendation or is this a method that was created by professionals as a way to make a clog go away? How much PSI can a housing take? Lid? Is it 40psi like PVC?

I was taught to stuff pipes and blast with Oxygen or Nitrogen, or cut pvc, cap it, drill a hole and tap it for a brass fitting for a compressor and blow it out.

Any info is appreciated.