Hello Henry,

I actually reply to your post a few days ago but I got bad internet connection and I lost all I typed....

I wanted to share with you all the trouble what my pool and my friend's pool got, both are concrete pool like yours.

My pool pump is above the pool. My friend's pool pump room ( a big one ) is below his pool deepest water line.

Here goes :

01. First take a look at this post, its about a leaking water inlet.

post82136.html#p82136

I don't understand pool construction or anything about concrete, except that concrete is porous and water will seep into it. unless special mix right ??

In my country, builder use a special paint to waterproof the concrete. The paint dried to become like waterproof membrane. So its not solid rubber membrane or the sort. Later the wall will be tiled.

If I am correct, whatever pipes they install on the concrete for water inlet or suction gets embedded inside the concrete when the concrete is poured in. What I don't understand is the waterproofing used between the pipe outer diameter to the concrete itself. I know when they install the fittings, the local builder uses those clear silicone like those on glass aquarium. So I think there is always a possibility of micro leak between the PVC pipe outer wall and the concrete that surrounds it, applying clear silicone will stop possible leakage but I don't know for how long.

I work on fiberglass boats. I install a few underwater fittings like engine cooling intake valves and fishfinder transducer. I use 3M polyurathane sealant for this job but I can apply it easily and properly both inside the hull and outside the hull. So the sealant really works well and there is always a fitting/washer that is bigger than the drilled holes covering both side of the hole, so the sealant can be spread out properly to create a proper water tight fitting that will last at least 10 years if not more. This fitting also get screwed in, so there is also added mechanical fastening.

You mentioned "syncoflex", I read the datasheet, it looks good.... I wish they sell those here.

02. Water heater. Have bypass valve and plumbinbg ready. When not in use don't pass thru chlorinated water there, its such a waste on the copper pipes. My friend pool has a gas type Pentair water heater and the water flow friction is high, so I asked the pool supply shop to install a bypass valve. The result is better water flow and those copper pipes should last longer. Check and make sure that your heater heater has a safety switch where when there is no water flow, it will not allow itself to be turned ON. I think such safety should be standard but beter check than sorry. No water flow and heater being on can damage the heater right ?

03. My friends pool has about 10-11 water inlets. His water inlets are positioned very deep, almost near the pool bottom. Mine is only 30-40 cm below pool surface. The builders said that since water heater is being used, if those water inlets are not placed very low, poor mixing will occur. Have you consider this possibilty ? If I read your post correctly, you will use only 3 water inlets. Are you sure those will provide fast hot water mixing ? I think some expert opinion is needed here.

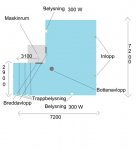

04. I never use a skimmer and never seen one. Your photo shows a skimmer placement in what will become the pump room. Are the skimmers serviceable, I mean do you need to open up for cleaning ? Will your pump room ceiling be as high as the pool surface, if so, will there be enough headroom for you to service the skimmers ? Just a thought, it seems the skimmer is so high up and you may have a hard time servicing it if your ceiling is not higher than the pool top water surface.

05. Having an underground pump room or any pump room that is below pool waterline means there is a potential for flooding.

My friend's pump room has a submersible pump and a flood alarm. It also has 2 ventilation shaft made of 8" PVC pipe. 1 has a centrifugal blower to exhaust hot air and naturally fresh air get sucked in by the other air shaft. Its hot here in this country.

I bet your country regulation dictates that you must use GFI/ELCB or equivalent to guard against possible water spray or flooding causing electrical short circuit in the pump room. My friend's pump room use GFI/ELCB for each equipment ( located in pump room ) and a main GFI/ELCB in the house main panel high and dry. So in worst case flooding scenario, the 3 phase electrical supply will be shut down safely from the source. My friend has an unlucky crack on the sand filter neck, it nearly flooded the room if it weren't for the submersible pump. The pipe that sends out the water from the submersible pump when routed to the city drain, make sure it has a goose neck or 1 way valve ( check valve ) or whatever method you may use to prevent water from the drain to flood your pump room when there is a big rain or other possible scenario.

06. Having underground pump room is more difficult for maintenance and so on even though it looks "clean". Whatever benefit you get from less suction effort will be wasted in pushing the water up, depending how high is the water inlet in the pool will be located above the pump impeller. You will need more valves to isolate pumps and filters for servicing when they are all located below pool water level. Make a bigger pump room than estimated. The pipes run and bends will need more space than you usually imagine, unless you have done similiar piping before. Every" L" bends ( elbow ) on rigid pipe will take extra 6 to 8 cm of extra space for the fittings, I think that's the figure.

07. Try to have the water inlets, all of them on same depth. My friend's pool due to its unique 2 pool in one shape, has a few water inlets located shallower in the adjoining kids pool. The pressure loss is greater due to distance and those water inlets being much higher than the adult pool, makes waterflow so weak in the kids pool. The bad effect is that the kids pool water surface does not move fast enough to send the airborne dust on water surface to the overflow. This pool has no skimmer, it overflows out to the gutter on the side of the pool.

08. My pool also has a "leak" but its because the builder forgot to waterproof the side top surface of the concrete before they place the natural rock tiles. Since my pool overflows itself to a gutter surrounding the pool perimeter, 30cm of concrete that has no waterproofing caused me 400 liter a day of water. I don't know the long term effect it will cause to my concrete work surrounding the pool.... :| . You have a skimmer so it should be allright for you.

Good luck with the projecy Henry...

All the best. Hope my info is useful.

Cheers

You had mentioned using the flaps that came with the skimmers to adjust the suction - forget that! run each on a separate line with a valve that can control the suction - believe me, you'll get much better results that way! Also have a valve on the bottom drain line, you can use either 2, 3 way valves or 3 good quality ball valves (the one for the bottom drain should be of the highest quality!). If you do as I suggest, controlling the flow performance will be easy as will vacuuming (assuming you'll use one of the skimmers to vacuum) and winterizing the pool (yeah, I know you don't even have it built yet, let alone swam in it, but preparing for future winters will save a lot of trouble when that time comes

You had mentioned using the flaps that came with the skimmers to adjust the suction - forget that! run each on a separate line with a valve that can control the suction - believe me, you'll get much better results that way! Also have a valve on the bottom drain line, you can use either 2, 3 way valves or 3 good quality ball valves (the one for the bottom drain should be of the highest quality!). If you do as I suggest, controlling the flow performance will be easy as will vacuuming (assuming you'll use one of the skimmers to vacuum) and winterizing the pool (yeah, I know you don't even have it built yet, let alone swam in it, but preparing for future winters will save a lot of trouble when that time comes