- May 3, 2007

- 17,086

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

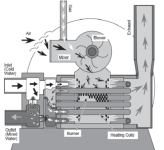

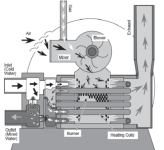

The Master Temp 400 has an internal bypass:

This is much better than heaters without a bypass such as most heat pumps but not as good as an external bypass.

To give you an idea of performance difference in a similar setup to yours, with the heater in-line and the pump at full speed, the operating point would be around:

107 GPM @ 69' of head & 2412 Watts

With the heater externally bypassed:

124 GPM @ 62' of head & 2613 watts

If you reduced the RPM (2975) of the external bypass scenario such that the flow rate is the same as without an external bypass, the operating point becomes:

107 GPM @ 46' of head & 1719 Watts

So you can either get more flow rate or fewer watts or a combination of both with the bypass.

Savings are much less at lower RPM.

But the other reason to have a bypass is so you can isolate the heater should you even need to a harsh chemical treatment of the water and/or maintenance on the heater.

This is much better than heaters without a bypass such as most heat pumps but not as good as an external bypass.

To give you an idea of performance difference in a similar setup to yours, with the heater in-line and the pump at full speed, the operating point would be around:

107 GPM @ 69' of head & 2412 Watts

With the heater externally bypassed:

124 GPM @ 62' of head & 2613 watts

If you reduced the RPM (2975) of the external bypass scenario such that the flow rate is the same as without an external bypass, the operating point becomes:

107 GPM @ 46' of head & 1719 Watts

So you can either get more flow rate or fewer watts or a combination of both with the bypass.

Savings are much less at lower RPM.

But the other reason to have a bypass is so you can isolate the heater should you even need to a harsh chemical treatment of the water and/or maintenance on the heater.