- Jul 21, 2013

- 53,609

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I realize that I thought you had a H250FD forced draft heater and the Hayward H250ED2C is a different natural draft model.

www.hayward-pool.ca

www.hayward-pool.ca

The Hayward H250ED2C is no longer listed on Hayward CA website.

If you replace the heater I would give the Universal H Series heater a try.

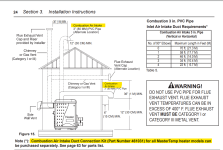

The indoor air requriements for your H250EDC as similar to what I posted above....

Universal H-Series | Hayward Canada

Hayward's pool heater saves money by being the most energy efficient solution for any pool/spa. It's designed for ultimate performance, comfort and durability while being environmentally responsible. For rapid comfort, we offer the Universal solution.

The Hayward H250ED2C is no longer listed on Hayward CA website.

If you replace the heater I would give the Universal H Series heater a try.

The indoor air requriements for your H250EDC as similar to what I posted above....