Am I missing something or why can't I just use a current sensor to turn my SWG on and off. I know the pump is 220V but shouldn't really matter if I get one leg, if it's running allow power to SWG..If not don't..

I have wired everything including replacing the breaker box so nothing I couldn't handle

My pump doesn't have a relay

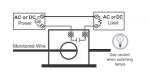

Here is what I am looking at.

I have wired everything including replacing the breaker box so nothing I couldn't handle

My pump doesn't have a relay

Here is what I am looking at.