- May 23, 2015

- 24,405

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

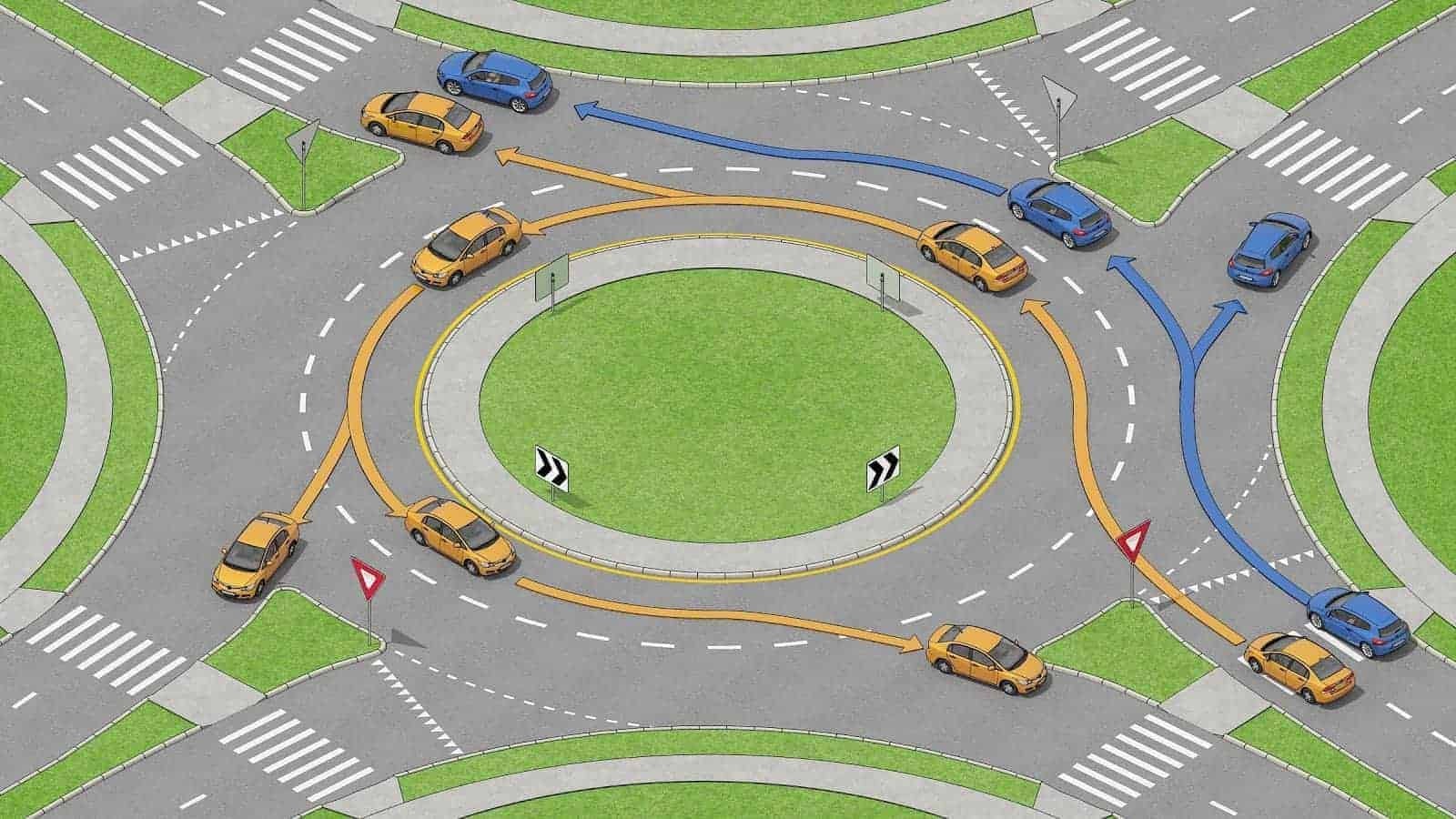

That is because we have poorly designed entrance ramps with inadequate acceleration lanes. If road engineers needed to design entrance ramps for slow acceleration they could.

It’s the same argument as pools having poorly designed systems with excessive head loss.

The cars and the pumps are built to match the roads and pools that are built.

Says the guy that lives in New Jersey’s where everything is jug-handle and left turns are prohibited…