So I was able to get about two inches of the top of the original pipe exposed. Again does anyone know which manufacture or model skimmer I should get to get the original 11 inches? Or which skimmer is the best or strongest? Also where should I buy the concrete mix? And why isnt the rebar coated like the rebar they use to build bridges where I live? I know some people said I will have to some more demo, yes, but what ever is neccesary to fit in the new skimmer. I also have to buy a hammer drill, and smalldic grinder, but what type of disc for the grinder?

The guys who've already responded are much more knowledgeable than I am, but I recently replaced a skimmer so I'll try to answer a few of your many questions.

In order:

As mentioned, it doesn't really matter which skimmer you get, you don't need to match the size of the existing one. What you need to do is chip/cut out a lot more concrete and dig down to expose more of the plumbing, after which you can adjust the plumbing to set it where it makes sense, not necessarily based on where the old plumbing is. You'll want at least ~4 inches of space on every side around the skimmer (including below it). The more space you have the easier the work will be. I tried to minimize chipping and digging to minimize the amount of concrete to pour later, which in hindsight was a terrible way to do it.

I like to mix my own concrete, but any medium to high strength concrete mix should work.

The rebar will be (or at least should be) completely encased by concrete by the end of this project, so there's no need for it to be coated.

A circular saw with a diamond masonry cutting blade and a small angle grinder with a diamond grinding cup would both be very helpful. A diamond masonry cutting wheel for the angle grinder could also come in handy.

Mostly videos on Youtube. They reccomend putting rebar around the back of the skimmer to hold it to the bond beam, and drill holes into the bond beam and insert the ends of the rebar and glue them in. I will have to buy a Bosch hammer drill, which model do you reccomend?

Doesn't need to be a Bosch, can be any hammer drill. Since you have a lot of concrete that needs to be chipped out, a combo demo hammer / hammer drill would be very helpful. Harbor Freight has a couple very affordable ones, and while the quality isn't the best, they should be plenty good enough for this job. I personally like to drill the holes at an angle and then insert and bend the rebar, which creates a very strong mechanical bond in addition to the bond from the epoxy. It's easiest to drill the holes downward at about a 45° angle, insert the rebar loops without the skimmer in place, bend the loops down until they're flat, and then plumb the skimmer in. And make sure you get all the debris and dust out of the holes before you epoxy in the rebar, otherwise the epoxy won't bond well.

I used a large shop vac to clean out the hole. I read I need to clean the concrete with acid first before I pour in the rest to fill up around the skimmer? Do I neutralize that before I pour in the rest of the concrete? I also saw them using some type of grinding wheel to get the surface of the concrete flat before the pour on the plaster layer, which grinder do I use for that? I guess thats a grounding wire in the photo, why is it so close to the skimmer? Also how do I know if the pipe below this skimmer is attached to the pipe thats at the bottom of the pool? I dont think it is. I understand that if the water level drops below the level of the skimmer there should be an automatic closing valve in the bottom of the skimmer to make sure the pumps prime doesn't fail so the pump doesn't run dry, should I buy a skimmer with this valve? My other Sylvan skimmer doesn't have that, but should I install one in it?

You do not need to use acid. Using an acid wash that's too strong will actually weaken the top layer of concrete and result in a weaker bond. Just clean the existing concrete very well and make sure it's completely free of dirt, dust, and debris. If you insist on using acid, then yes, it needs to be neutralized with a baking soda solution and then rinsed very well before pouring the new concrete. If you chip things out properly there likely won't be much concrete to worry about bonding to, just the bond beam between the skimmer and the pool.

I'm not sure what surface you're talking about grinding flat. Maybe salvaging the bond beam portion of the throat? In any case, the diamond grinding cup I mentioned above should work for grinding any needed flat spots in the concrete.

I also don't know what plaster layer you're talking about pouring, so I can't really help with that..

It's likely a bonding wire, which is different from a ground wire.

If there's only one pipe below the skimmer, that's your skimmer intake that should run to your pump. If there were two pipes, then one would likely connect to your main drain. I think the valve you're referring to is a diverter valve, which only applies when you have two pipes, so don't worry about it.

What mixture concrete to use? Do I put plaster behind the tile and then the thinset mortar on top of that? Should I grind grooves into the surface behind where the tile will be so the thinset or plaster grabs better?

Any medium or high strength concrete mix should work. I made my own M40 concrete mix, which would be considered a high strength concrete.

You shouldn't need to do anything with plaster. The skimmer throat needs to be encased in and sealed to the concrete, the tile gets applied to the concrete in front of the skimmer throat using a thinset rated for submerged applications. You shouldn't need any grooves in the concrete, just don't make the concrete super smooth when you float it.

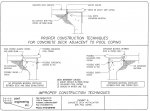

Here's the article

@PoolguyinCT mentioned above:

Skimmer Replacement, Part 2: In With the New - AQUA Magazine