- May 5, 2021

- 8

- Pool Size

- 21500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-9)

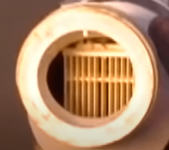

I have a Hayward T9 salt cell that's at the end of it's useful life, it has been confirmed as failed, requiring replacement. Fortunately it's still under Hayward warranty and a claim has been filed with Hayward. Unfortunately Hayward is unable to provide any replacement cells for at least 3 months (supply chain issues...). In the meantime I've resorted to liquid chlorine.

My question is this: Would temporarily wiring up the salt cell to an external 24VDC power supply be able to squeeze a little more chlorine-producing life out of the cell, or would that risk adverse side water chemistry, for example metals electro-migration from having a dissipated ruthenium oxide coating? The Hayward PL-PS4 controller will currently not turn on power to the salt cell as it (incorrectly) measures the salt level (conductivity) as too low, even though it's 3400ppm. In a simple test, using an external 24VDC PSU will cause the cell to draw around 2.5 amps and produce chlorine.

My question is this: Would temporarily wiring up the salt cell to an external 24VDC power supply be able to squeeze a little more chlorine-producing life out of the cell, or would that risk adverse side water chemistry, for example metals electro-migration from having a dissipated ruthenium oxide coating? The Hayward PL-PS4 controller will currently not turn on power to the salt cell as it (incorrectly) measures the salt level (conductivity) as too low, even though it's 3400ppm. In a simple test, using an external 24VDC PSU will cause the cell to draw around 2.5 amps and produce chlorine.