Greetings,

Let me first say, thanks for a great site and for all of you who share your knowledge to help take away the mystery and much of the fear of DIY pool care, I became a TFP supporter and went to Pool School and have had nothing but crystal clear water ever since.

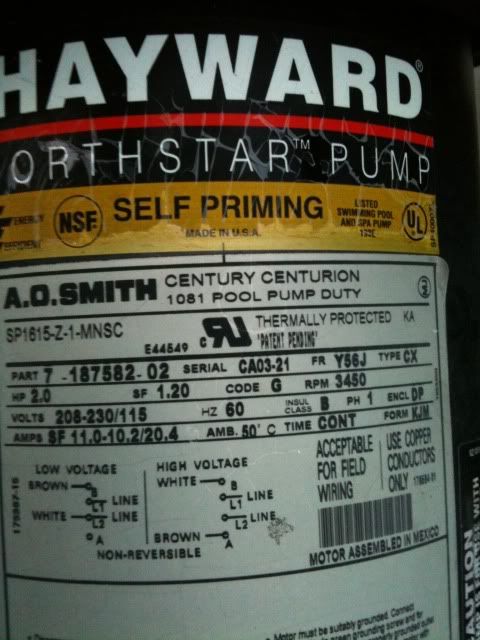

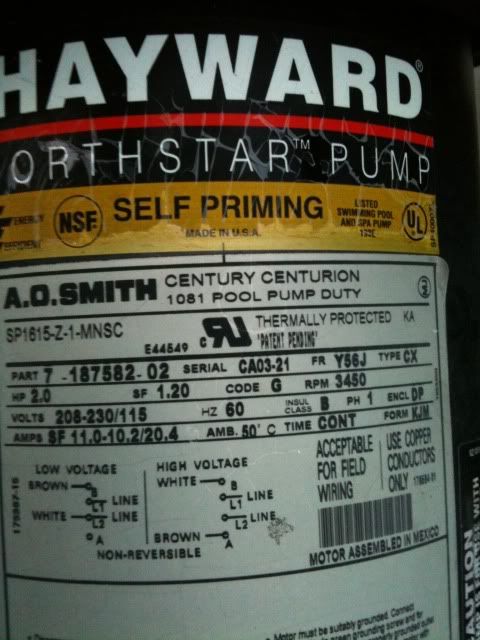

The problem I am having now is that I believe i ran the water line too low and ran the pump dry too much specially on the initial start and burnt the bearing. At first it sounded just a bit like a clothes dry with a elliptical sounding rotation, then one morning i was there when the timer began the pump and it was seized for about a minute before it started and it still ran and pushed enough water to vacuum with but at this point it sounded much more like a 6 cyl firing on 5 cylinders. Good news bad news, its fall in the northeast and the pool is now closed and i have a few frigid months before its season again so i have time to perhaps rebuild this unit myself.

Seems the impeller is pressed onto the shaft, anyone have a suggestion on removing, im guessing a puller, but any input on redoing this pump would be appreciated.

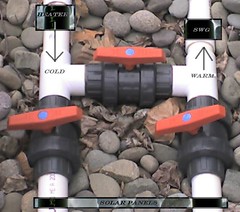

Other consideration, ditch the pump and upgrade to to a 3hp pump, I have never really been able to run my discharge propelled cleaning unit, doesnt seem to zoom it enough, always stuck in the deep, I also run a bank of 10 solar panels, about 25 feet from the pump that definitely puts a bit of a load on it. I figure it is not so bad cause the flow is slower to move through absorbing more heat.

Any input greatly appreciated including jokes about me being an idiot for burning out a three year old pump...

Thanks,

Evan

Let me first say, thanks for a great site and for all of you who share your knowledge to help take away the mystery and much of the fear of DIY pool care, I became a TFP supporter and went to Pool School and have had nothing but crystal clear water ever since.

The problem I am having now is that I believe i ran the water line too low and ran the pump dry too much specially on the initial start and burnt the bearing. At first it sounded just a bit like a clothes dry with a elliptical sounding rotation, then one morning i was there when the timer began the pump and it was seized for about a minute before it started and it still ran and pushed enough water to vacuum with but at this point it sounded much more like a 6 cyl firing on 5 cylinders. Good news bad news, its fall in the northeast and the pool is now closed and i have a few frigid months before its season again so i have time to perhaps rebuild this unit myself.

Seems the impeller is pressed onto the shaft, anyone have a suggestion on removing, im guessing a puller, but any input on redoing this pump would be appreciated.

Other consideration, ditch the pump and upgrade to to a 3hp pump, I have never really been able to run my discharge propelled cleaning unit, doesnt seem to zoom it enough, always stuck in the deep, I also run a bank of 10 solar panels, about 25 feet from the pump that definitely puts a bit of a load on it. I figure it is not so bad cause the flow is slower to move through absorbing more heat.

Any input greatly appreciated including jokes about me being an idiot for burning out a three year old pump...

Thanks,

Evan