I have an in-ground, salt swimming pool. The entire setup is outdoor in a city that snows a lot (motor, salt panel, heater, filter). My motor (Hayward Super Pump) has lasted 7 years up until a few weeks ago. The pool company replaced the capacitor which lasted 3 weeks. When I brought the motor back for repair, the technician told me that the motor was completely burnt. They told me that usually pumps last 10-15 years, and the reason mine didn't was because it was running on 120 Volts.

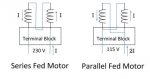

I am not an electrician, but the concept seemed strange to me. I thought that we always used 120 Volts in North America and 240 Volts in Europe? Is it even possible to install a 240 Volt outlet for residential use?

I am wondering if this sounds legitimate and if you guys also have your motors connected to 240 Volts.

Thanks in advance

I am not an electrician, but the concept seemed strange to me. I thought that we always used 120 Volts in North America and 240 Volts in Europe? Is it even possible to install a 240 Volt outlet for residential use?

I am wondering if this sounds legitimate and if you guys also have your motors connected to 240 Volts.

Thanks in advance