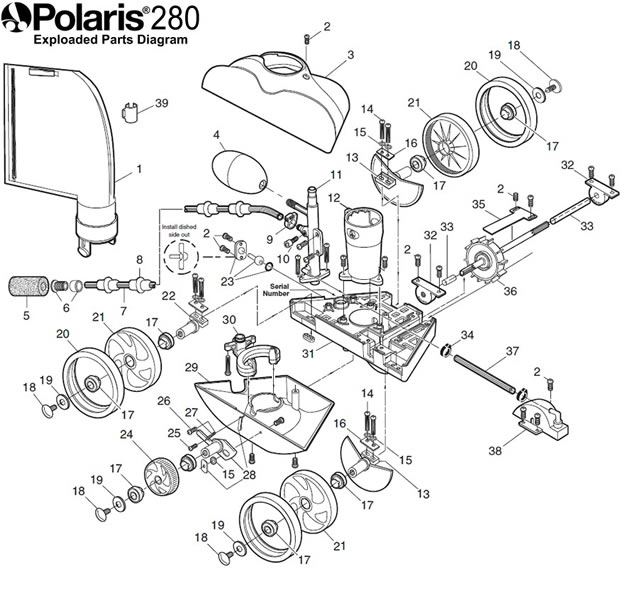

Hi, I have a Polaris 280 that stopped moving, as in, no movement of the drive wheels. It was due to have the wheel bearings and turbine bearings replaced. I have hat it completely apart. There are no blockages in any lines, tubes, or passages. I replaced the water management system while I had it apart because it was brittle. Mechanically, I see no fault in the parts of the unit to cause it not to work.

When I completed the rebuild and put it in the pool, the flow of water was stronger than usual from the rear directional jet and from the two upward ports of the water management system. The reverse valve, which is new, functioned properly at a 3 minute interval. But there was no apparent flow to the turbine on the drive axle. The drive wheels were appropriately tight and all 4 wheels (the 2 drive wheels, idle wheel, and non-drive wheel) turned in unison by hand. At this point, there are no moving parts in this Polaris 280 that have not been replaced in the last 12 months. Can anyone point me in the right direction?

Thanks,

Greg

Bewildered in Woodstock, GA

When I completed the rebuild and put it in the pool, the flow of water was stronger than usual from the rear directional jet and from the two upward ports of the water management system. The reverse valve, which is new, functioned properly at a 3 minute interval. But there was no apparent flow to the turbine on the drive axle. The drive wheels were appropriately tight and all 4 wheels (the 2 drive wheels, idle wheel, and non-drive wheel) turned in unison by hand. At this point, there are no moving parts in this Polaris 280 that have not been replaced in the last 12 months. Can anyone point me in the right direction?

Thanks,

Greg

Bewildered in Woodstock, GA