Hi everyone,

Like many others, we invested one of our kid's college savings into a pool build during the pandemic

I've now got a hole in my yard and the pool builder is giving me grief about where I want my pool equipment to be placed.

I want to have the equipment about 60 feet from the skimmer and the PB is telling me it can't be more than 30 feet or "things won't work" or "the pump will be strained" or "insert whatever why else it won't work".

Quick context: the guy I'm dealing with used to be a car salesman and is an expert at tacking on extra $$$ for anything I've expressed I wanted (even if logically it would imply less labor or material...)

I don't know anything about pools or the plumbing outside of the stuff I've read here for the past 3 days. It's all very confusing. So after reading similar questions here I decided I call Pentair customer service since all equipment is Pentair. I spoke to one gentleman who sounded like was running some calculations (30-40 PSI, 160 GPM, 14K Gallons, etc) and he said what I wanted should be fine but before I could ask him to elaborate on those calculations the line got disconnected. I called back and got a different representative who didn't even do any calculations or ask too many questions and simply said "you should have no problems running anything under 100 feet with 2" pipe - we test all our equipment to 100 feet". That answer somehow doesn't really sound reliable especially if he didn't ask for a lot of the variables that could go into that equation. So here I am. Hoping you experts can arm me with what I need to go back to the PB.

My specs:

Pool is 14 x 29, 3.5 - 5.5 ft deep. There's a 7 x 7 spa in the corner (within) the pool.

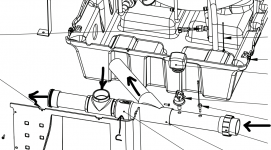

They already have a 2" pipe connected to skimmer and what looks like 2.5" pipes hooked up to Spa and Pool drains.

Pool is ready for gunite at this point, so there's no equipment or other plumbing runs yet.

Equipment to be used:

They have not provided me with a "plumbing plan" so I have no other details to share other than the above. My questions are:

Best regards,

Sparq

Like many others, we invested one of our kid's college savings into a pool build during the pandemic

I've now got a hole in my yard and the pool builder is giving me grief about where I want my pool equipment to be placed.

I want to have the equipment about 60 feet from the skimmer and the PB is telling me it can't be more than 30 feet or "things won't work" or "the pump will be strained" or "insert whatever why else it won't work".

Quick context: the guy I'm dealing with used to be a car salesman and is an expert at tacking on extra $$$ for anything I've expressed I wanted (even if logically it would imply less labor or material...)

I don't know anything about pools or the plumbing outside of the stuff I've read here for the past 3 days. It's all very confusing. So after reading similar questions here I decided I call Pentair customer service since all equipment is Pentair. I spoke to one gentleman who sounded like was running some calculations (30-40 PSI, 160 GPM, 14K Gallons, etc) and he said what I wanted should be fine but before I could ask him to elaborate on those calculations the line got disconnected. I called back and got a different representative who didn't even do any calculations or ask too many questions and simply said "you should have no problems running anything under 100 feet with 2" pipe - we test all our equipment to 100 feet". That answer somehow doesn't really sound reliable especially if he didn't ask for a lot of the variables that could go into that equation. So here I am. Hoping you experts can arm me with what I need to go back to the PB.

My specs:

Pool is 14 x 29, 3.5 - 5.5 ft deep. There's a 7 x 7 spa in the corner (within) the pool.

They already have a 2" pipe connected to skimmer and what looks like 2.5" pipes hooked up to Spa and Pool drains.

Pool is ready for gunite at this point, so there's no equipment or other plumbing runs yet.

Equipment to be used:

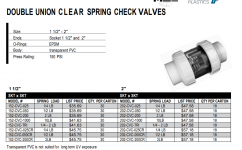

- Pentair IntelliChlor IC40 Salt Chlorine Generator

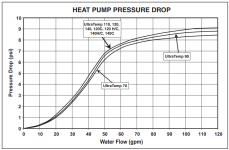

- Pentair UltraTemp 120Q Electric Heater (127K BTU) - Almond Color

- Pentair IntelliFlo VSF Variable/4-speed Pump

- Pentair Filter Cartridge (Clean and clear - CC150)

They have not provided me with a "plumbing plan" so I have no other details to share other than the above. My questions are:

- With the equipment I have, will the 2" pipe work at 60 foot run without straining the pump too much, or

- Should I ask for them to install larger pipe to ensure there's no problems, or

- Is the PB correct and I need to move the equipment closer to avoid problems with our equipment and/or efficiency of it.

Best regards,

Sparq