I did call Pentair, and they suggested I see what happens when I run the pump a little faster or a little slower.

So I tried slower at 1500 and 1400 rpms, and the pump shut down faster than at 1600.

Then I tried 1700, and it was OK

Then I tried 1630rpm. This one was interesting... after about 15-20 seconds, it started vibrating again. Then after 30-60 seconds of that, the vibrations died down and everything was fine again. Also, the display shows a power meter... it would start out around 250W, then as the vibrations started, it would steadily climb up to around 600W, then as the vibrations died, it would steadily decrease back to 250W. After this initial vibration period, the motor seemed to run fine for the rest of the time (I only stuck around for 3-5 minutes, but the motor remained stable during that time).

I called Pentair back after that, and I got a different tech on the line. He suggested that the motor itself was going bad. His reasoning was mostly based on the fact that the motor was vibrating at the low speeds.

@CA92807, You said you had the exact same problem, and it was blamed on the controller. When you said you got a replacement... was it a replacement of the controller module that sits on top of the motor, or the whole pump? If the whole pump was replaced, did you by chance just swap the controllers to see if that helped?

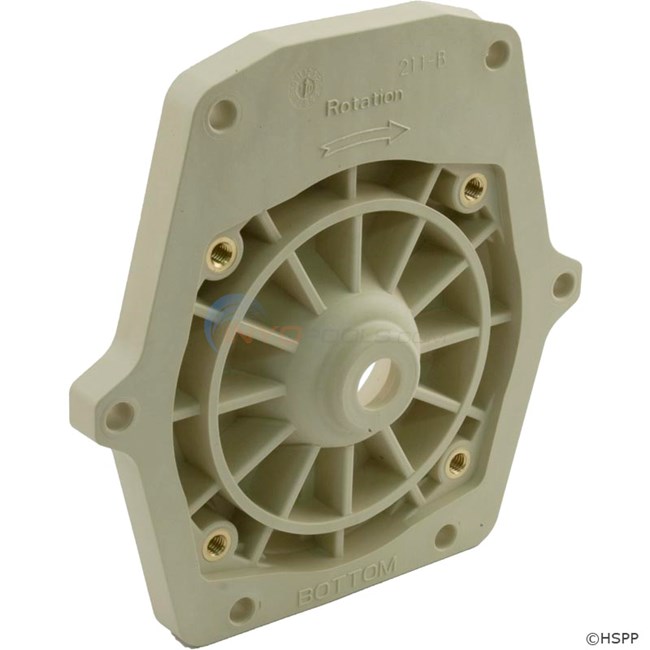

@JamesW, I don't have pictures, and I don't particularly want to disassemble the pump again to do that... sorry. But the seal plate appears to be in good shape, and there are no leaks. The impeller and diffuser and their contact points look fine to me... nothing inside seems abnormally worn. I'm not sure what brass grommets you're referring to... I don't see them on the parts diagram in the manual.

Thanks again.