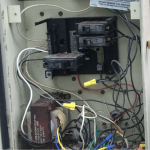

Well, bad news. I've rewired the motor for 230V and in a stand alone mode (straight water pipe in, straight water pipe out) the motor is running about 18A - which is half of 115V operation and the same problem persistis :-(. The thermal switch is shutting off the motor after a few seconds of operation.

So I've run out of ideas - any other thoughts from anyone? Thanks!!!

So I've run out of ideas - any other thoughts from anyone? Thanks!!!