Hi Everybody,

We are getting into a new pool / spa build very soon - working with several builders and got a few bids. The pool is fairly basic rect 32x18 gunite pool with spa for 8 people that is elevated 16" above the pool and spills over into the pool through an opening that is about 8' wide.

By all accounts - this is a common design. Initially my landscape architect that designed the pool specified two pump system - a variable speed filter pump and a spa booster pump. I read over that line without really comprehending what any of these things mean. Then one PB I talked with suggested I use a single larger variable speed pump (citing such reason as: sufficient, cheaper, less noise, and a few others).

So at that point I started reading about these things and, oh my! In all, I think I spent about a week getting plumbing education, half of it lurking right here in TFP.

I think most of my questions have been answered to a large degree in various threads. The reason for "yet another thread" is to just clear up a few things I did not find, hopefully it is useful to others in my situation that are looking for overlooked details.

Let me first start with design objectives:

1. Water circulated by the dedicated jet pump is not passing through the heater. It will travel about 50-60' from spa drain #2 through the pipes in one directions before being returned over another 50-60' to the spa jets. Will it be uncomfortably cold by the time it is returned to the spa and through the jets?

2. The two 3-way valves can be set (with actuators to be controlled by Pentair IntelliCenter) as follows:

# drain valve supply valve

A. pool pool some spillover due to make up valve returning at least "some" water to the spa. (pool temp)

B. pool spa this will spillover all water since nothing is returned to the pool. Variable speed controls amount of spillover (pool temp).

C. spa pool apart from draining the spa I don't see use for this - perhaps it can be disabled so electronic valve actuators will not use this

D. spa spa (all good here, no spillover, spa temp, heater / filter / chlorinator work on spa only)

The question is this: in pool/pool setting - how can amount of water sent to spa vary. I want to make sure that spa chemistry is maintained AND that it looks good by spilling some water into the pool all the time. Can makeup valve be adjusted (like a ball valve) to desired amount? Should I just always use mode B above (pool/spa and never return water to pool directly, and if so what would be bad about that?)

3. I understand different jets have different GPM ratings and adding them up will result in the combined GPM that a pump needs to supply. These things are not super expensive it seems, so I wanted to select something that is high quality and can give me 8 jets in the spa. A lot of people express concerns when using more than about 6 jets. But using the design I describe above and upsizing the plumbing to 2.5" what type of jets should I use?

4. Will spa jet outputs be properly balanced? What seems to be common is to use a manifold (usually a ring) with special ports for jets and a supply. I am not sure, but would the jets on the manifold farther from the supply line experience less pressure than those near the supply line? Are there per jet valves that need to be "tuned" to ensure equal amount of water is available to each jet?

5. another question about the jets - are there any that allow user to adjust/close them off? For example if I am in the spa and I want jets and my wife does not - can she turn a "knob" on the jet and temporarily reduce / turn off 2-3 of them? This seems like it should be a thing but I can't seem to find any information on the adjustments like that.

6. My last question is about the noise from the pad. My equipment pad is unfortunately located (due to site constraints and township setback rules) not too far from the "recreational" area so I am a little concerned about the noise. Is the pentair intelliflo pump reasonably quiet when running at low rpm? Are there better, quieter pumps? It is not as important but the heater that one builder I got a bid from recommends is a pentair mastertemp 400btu - and the extra noise from that device is the fan running inside. So same question here, is that heater quiet and are there quieter heaters?

Thanks for reading and any feedback

We are getting into a new pool / spa build very soon - working with several builders and got a few bids. The pool is fairly basic rect 32x18 gunite pool with spa for 8 people that is elevated 16" above the pool and spills over into the pool through an opening that is about 8' wide.

By all accounts - this is a common design. Initially my landscape architect that designed the pool specified two pump system - a variable speed filter pump and a spa booster pump. I read over that line without really comprehending what any of these things mean. Then one PB I talked with suggested I use a single larger variable speed pump (citing such reason as: sufficient, cheaper, less noise, and a few others).

So at that point I started reading about these things and, oh my! In all, I think I spent about a week getting plumbing education, half of it lurking right here in TFP.

I think most of my questions have been answered to a large degree in various threads. The reason for "yet another thread" is to just clear up a few things I did not find, hopefully it is useful to others in my situation that are looking for overlooked details.

Let me first start with design objectives:

- I want to control how quickly all of the water circulates over the filter / chlorinator / heater. To accomplish that I want to have a variable speed main filter pump. This pump should be running at slowest allowable speed normally and only increasing when needed (this is both most efficient for energy use and for less pump noise).

- While in normal pool mode the water in the spa should spill into the pool as a matter of normal operation, I don't really want to treat this as a water "feature" - with spillover this will look much better.

- I want to be able to adjust the volume of water spilled over - this adjustment is probably a one time thing and can be set once - I don't really need/want to "tinker" with it as long as it is spilling evenly and visually pleasing. The spillover does not have a hanging lip/edge, just 1" mosaic tile on top of spillover wall meeting same tile on the wall at a slightly acute angle and water goes down the tiled wall into pool.

- I want to have good control over jet performance in the spa when spa is in use (spa mode). We have an air booster specified as well but beyond turning that on and off - I want to have control over how much water is coming out of the jets. Including turning the jets off completely. (and just enjoying the hot soak)

- I am concerned that a lot of people have issues with anemic jet performance - so I think being able to adjust it with a powerful variable speed pump and proper size plumbing (2.5" enough?) gives me the best chance to actually get good performance from jets "by design"

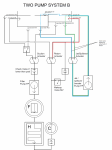

- a primary filter pump (currently a Pentair Intelliflo variable speed 3HP pushing water through filter, heater and chlorinator (I will not be using an SWG).

- two sets of drains in spa - set #1 to the primary pump and a separate set #2 to a dedicated variable speed jet pump

- a second variable speed (perhaps the same type as #1) connected directly to spa drain set #2 and spa jets distribution manifold without going through heater / filter / chlorinator. This minimizes losses and should maintain flow to jets when it is on. The pump can be operated at 8 different preset speeds and can also be turned off for "soaking" time. I am hoping to put in 8 jets into the spa.

- separate hot water returns on spa bottom (not connected to jets)

- makeup valve to hot water returns in spa when in pool mode (as I understand, this is what will make spa spillover in pool mode).

- standard 3-way valve on pool drain / spa drains #1

- standard 3-way valve on pool returns / spa hot water returns

1. Water circulated by the dedicated jet pump is not passing through the heater. It will travel about 50-60' from spa drain #2 through the pipes in one directions before being returned over another 50-60' to the spa jets. Will it be uncomfortably cold by the time it is returned to the spa and through the jets?

2. The two 3-way valves can be set (with actuators to be controlled by Pentair IntelliCenter) as follows:

# drain valve supply valve

A. pool pool some spillover due to make up valve returning at least "some" water to the spa. (pool temp)

B. pool spa this will spillover all water since nothing is returned to the pool. Variable speed controls amount of spillover (pool temp).

C. spa pool apart from draining the spa I don't see use for this - perhaps it can be disabled so electronic valve actuators will not use this

D. spa spa (all good here, no spillover, spa temp, heater / filter / chlorinator work on spa only)

The question is this: in pool/pool setting - how can amount of water sent to spa vary. I want to make sure that spa chemistry is maintained AND that it looks good by spilling some water into the pool all the time. Can makeup valve be adjusted (like a ball valve) to desired amount? Should I just always use mode B above (pool/spa and never return water to pool directly, and if so what would be bad about that?)

3. I understand different jets have different GPM ratings and adding them up will result in the combined GPM that a pump needs to supply. These things are not super expensive it seems, so I wanted to select something that is high quality and can give me 8 jets in the spa. A lot of people express concerns when using more than about 6 jets. But using the design I describe above and upsizing the plumbing to 2.5" what type of jets should I use?

4. Will spa jet outputs be properly balanced? What seems to be common is to use a manifold (usually a ring) with special ports for jets and a supply. I am not sure, but would the jets on the manifold farther from the supply line experience less pressure than those near the supply line? Are there per jet valves that need to be "tuned" to ensure equal amount of water is available to each jet?

5. another question about the jets - are there any that allow user to adjust/close them off? For example if I am in the spa and I want jets and my wife does not - can she turn a "knob" on the jet and temporarily reduce / turn off 2-3 of them? This seems like it should be a thing but I can't seem to find any information on the adjustments like that.

6. My last question is about the noise from the pad. My equipment pad is unfortunately located (due to site constraints and township setback rules) not too far from the "recreational" area so I am a little concerned about the noise. Is the pentair intelliflo pump reasonably quiet when running at low rpm? Are there better, quieter pumps? It is not as important but the heater that one builder I got a bid from recommends is a pentair mastertemp 400btu - and the extra noise from that device is the fan running inside. So same question here, is that heater quiet and are there quieter heaters?

Thanks for reading and any feedback