Wow! So you're using a dual pole relay to switch a single pole (120V) device and using the 2nd pole to confirm the relay setting. That's a great idea!

Thanks! When I read this, I thought...so THAT's the correct terminology:

dual pole / single pole / 2nd pole. When I worked as an EE, I worked at the transistor level and we didn't have these kinds of relays, haha. Cliff, this project is slow going but my goal is to have feedback wherever possible. In this case, when I control a Stenner pump, I want to:

(1) verify that I at least "tried" to turn the Stenner pump "ON" via the output signal to it

(2) verify that the pump "turned on" (detect A/C current flow to Stenner pump, liquid level going down in tank as it is pumped out)

(3) TBD: verify that the chlorine/acid makes it to the pool (not pumping out in a puddle on my pad) by verifying that the chlorine/acid injection does what it is supposed to.

11) STENNER PUMP SOFTWARE

So I am getting very close on the Stenner control software on the Photon. I am NOT a programmer. When I start writing code, I realize I am doing something wrong, or that my requirements change, or that there is a better way. So, I rewrite the code...over and over and over again.

Over the last week or so, I have dug into what functionality I want from the Stenner pumps. I am currently going through a characterization of my pool's chemical needs and documenting it. In addition, I am conducting some experiments over the course of the summer. These experiments involve dosing sizes, dosing timing, and (since I am planning on draining my pool this fall) the impact of raising my CYA levels on my pool's chlorine needs.

To conduct some of these experiments, I realized that I needed the ability to slowly disperse chlorine throughout the sunny part of the day. Thus the "Chemical Dosing Operation" became a required need for me and I have included it in this Stenner Pump software control.

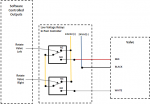

As I said before, I am not a programmer...so this is a diagram that gets the point across, but follows no convention (as I am unaware of the conventions). But just the fact of making this diagram (after I finished coding my latest implementation), has clarified what the requirements were. It also makes me want to rewrite the code again , haha.

I will have to read all of this when I have time, but that is a very ambitious project. Looks great so far.

I will have to read all of this when I have time, but that is a very ambitious project. Looks great so far.