I am a first time pool owner and our pool and spa is almost ready (we just filled it last Friday after plastering). The plumber hadn't installed the SWG when they did plumbing, but they had installed in-line chlorine feeder while we didn't have chlorine feeder in our contract (I don't know if they had installed it temporarily due to the SWG shortage? or they did a mistake and thought my pool would be chlorine?) Anyway, I talked to the builder and they came back on the weekend after the pool was filled, and installed the SWG (please see the photos of the equipment pad including the SWG). However, as you can see in the photo, they didn't remove the chlorine feeder and it is still there (I don't know whether the builder will remove it later or not). When the plumber was installing the SWG, I told him that there must be at least 12" of straight pipe in front of the cell inlet (per Pentair manual). But he said he couldn't do it since there was not enough space. That was my conversation with the plumber, but I haven't talked to the builder yet. My question is how important the minimum 12" straight pipe before SWG is? Is it something that you recommend me to talk to the builder and insist on fixing? If yes, what would be the options for fixing it considering that the plumber has almost finished his job (I am saying almost since he is still required to come back and install the heater when the equipment gets available). I would like to learn about the options before talking to the builder and he repeats the plumber words about the space. Thank you in advance. @Jimrahbe @mknauss @Texas Splash @HermanTX @ajw22 @Dirk

Incorrect installation of SWG?

- Thread starter tfp_fan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 52,449

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Pentair doe not say you must have 12” before the cell. The manual says:

Note: For best flow sensing, provide at least 12"-18" of straight pipe in front of the cell inlet.

They also say:

Install IntelliChlor SCG cell vertically for best performance.

Your plumber lacks imagination. He can easily go vertical along the square box he created and go 90 up, 12” of pipe, the cell, then 180 degrees down.

Many folks don’t have the 12” and their cell works fine. You can decide if you tell him to redo the cell.

If you do I would tell him to put it on the outside run rather then close to the filter. You will thank me when you need to work on the filter and remove the top. He didn’t leave you a lot of room to stand to work on the filter. Get rid of the leg where the SWG is now.

Note: For best flow sensing, provide at least 12"-18" of straight pipe in front of the cell inlet.

They also say:

Install IntelliChlor SCG cell vertically for best performance.

Your plumber lacks imagination. He can easily go vertical along the square box he created and go 90 up, 12” of pipe, the cell, then 180 degrees down.

Many folks don’t have the 12” and their cell works fine. You can decide if you tell him to redo the cell.

If you do I would tell him to put it on the outside run rather then close to the filter. You will thank me when you need to work on the filter and remove the top. He didn’t leave you a lot of room to stand to work on the filter. Get rid of the leg where the SWG is now.

Attachments

Last edited:

Fan,

I have about an inch before my cell and it works fine.. In my opinion you have plenty of room before the cell..

What you don't have is plenty of room around your filter. Under the filter is a drain plug.. How are you supposed to get it out?

The filter is also too close to the pump for my liking..

What else is going on your equipment pad?

And finally, I have no clue what the manual valve right after the filter output does. Do you know what it is for??

Do you know what it is for??

Thanks,

Jim R.

I have about an inch before my cell and it works fine.. In my opinion you have plenty of room before the cell..

What you don't have is plenty of room around your filter. Under the filter is a drain plug.. How are you supposed to get it out?

The filter is also too close to the pump for my liking..

What else is going on your equipment pad?

And finally, I have no clue what the manual valve right after the filter output does.

Do you know what it is for??

Do you know what it is for??Thanks,

Jim R.

- May 3, 2014

- 58,351

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I know that when my SWCG was installed originally, it had little straight run before it. My VS pump had to run at 1900-2000 rpm to close the flow switch. I had it redone to get close to 12" of straight run and the rpm dropped to 1500-1600 rpm to close the flow switch. Both with our heater installed. So there could be a small savings in rpm needed with more straight run before the SWCG.

- Feb 6, 2015

- 6,076

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

With that manual valve on the filter outlet set in its present location, you have part of the return water bypassing the salt cell and part going thru the salt cell. I wonder what the plumber was thinking.

Since you are waiting on the arrival of your heater, the plumber should have installed a proper heater bypass and stubbed out the heater pipes.

Plumber also didn't do you any favors in allowing easy access to the filter for cleaning.

Since you are waiting on the arrival of your heater, the plumber should have installed a proper heater bypass and stubbed out the heater pipes.

Plumber also didn't do you any favors in allowing easy access to the filter for cleaning.

- Jun 7, 2017

- 9,050

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

OK I am stumped. What is that valve for on the output of your filter? I honestly don't see a purpose for it.

@Jimrahbe @proavia @PoolGate Thank you for your good comment. I hadn't noticed it. I just took new photos from another angle which show the valve after the filter output. I really don't know why the plumber put it there? He was supposed to put a bypass for the heater, not for the SWG cellFan,

I have about an inch before my cell and it works fine.. In my opinion you have plenty of room before the cell..

What you don't have is plenty of room around your filter. Under the filter is a drain plug.. How are you supposed to get it out?

The filter is also too close to the pump for my liking..

What else is going on your equipment pad?

And finally, I have no clue what the manual valve right after the filter output does.Do you know what it is for??

Thanks,

Jim R.

Attachments

- Jun 7, 2017

- 9,050

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

Does anyone know if that SWG will detect flow if the flow is in reverse? That "bypass" doesn't really bypass anything since he did not put a one-way valve anywhere. It "kind of" bypasses the cell. I also agree with above he should have put some stub-outs for a future heater. Very odd plumbing indeed!

Question: Does Pentair make a filter with the input on one side and the output on the other? That is how my Jandy is setup. Jandy makes it both ways.

Question: Does Pentair make a filter with the input on one side and the output on the other? That is how my Jandy is setup. Jandy makes it both ways.

- Jul 21, 2013

- 52,449

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I think the plumber lost sight of the big picture. He initially installed a heater bypass, as requested, without the SWG with the plan to connect it to the heater. Then he got called back to install the SWG. He forgot what he previously did and simply looked at where to cut in the SWG, glue it in, and move on. Thus the mish mash of plumbing.

The plumber should redo the plumbing from the filter output to the pool/spa valve. It should be the heater bypass with stubs looped to install the heater and the SWG put vertically on the heater output side. Also a CV should be installed on the heater output as shown in Heater Bypass - Further Reading

Tell the plumber not to block in the filter on the right side.

Mark off with tape where the heater should be placed and where your future cooler will be placed. Leave room to work around the equipment and don't let the plumber push everything tight.

Give thought to where the MasterTemp heater exhaust will be. I think the heater should be at the right end of the pad. You don't want the heater exhaust going into the cooler next to it.

Where is the gas line for the heater located?

See if you have room to move the filter over a bit and give more room between the filter and the pump. The plumber may hate you but he already has a bunch of rework so now is the time to move the filter and leave room to work around the pump and filter.

While we are looking at what was done here. On the pool return side there are two pipes after the chlorinator and one of them has a check valve. What is the pipe with the CV for? If that pipe is for your spa spillover you need a diverter valve there to adjust the flow of the spillover or turn it off.

While the plumber is doing all the rework I would have him remove the chlorinater. You don't need it and it is just something that will eventually leak.

The plumber should redo the plumbing from the filter output to the pool/spa valve. It should be the heater bypass with stubs looped to install the heater and the SWG put vertically on the heater output side. Also a CV should be installed on the heater output as shown in Heater Bypass - Further Reading

Tell the plumber not to block in the filter on the right side.

Mark off with tape where the heater should be placed and where your future cooler will be placed. Leave room to work around the equipment and don't let the plumber push everything tight.

Give thought to where the MasterTemp heater exhaust will be. I think the heater should be at the right end of the pad. You don't want the heater exhaust going into the cooler next to it.

Where is the gas line for the heater located?

See if you have room to move the filter over a bit and give more room between the filter and the pump. The plumber may hate you but he already has a bunch of rework so now is the time to move the filter and leave room to work around the pump and filter.

While we are looking at what was done here. On the pool return side there are two pipes after the chlorinator and one of them has a check valve. What is the pipe with the CV for? If that pipe is for your spa spillover you need a diverter valve there to adjust the flow of the spillover or turn it off.

While the plumber is doing all the rework I would have him remove the chlorinater. You don't need it and it is just something that will eventually leak.

Last edited:

I know that when my SWCG was installed originally, it had little straight run before it. My VS pump had to run at 1900-2000 rpm to close the flow switch. I had it redone to get close to 12" of straight run and the rpm dropped to 1500-1600 rpm to close the flow switch. Both with our heater installed. So there could be a small savings in rpm needed with more straight run before the S

Good point, @ajw22 ! You are right. The plumber did this mistake since he originally thought the pool is chlorine. He had made that piping for the heater bypass. Then, he simply added SWG to that part and didn't notice it was wrong. Regarding your question about the gas line, it is the at the right side of the pipe which comes from the chlorinator with check valve. It means they are going to install the heater next to the SWG, and the space at the right end of the pad would be remained for the future chiller. In that case, the heater exhaust will go into the cooler next to it. Oh my god, so many thing should be corrected. I guess both the builder and plumber will hate me. Not sure if they accept to do all those jobs.I think the plumber lost sight of the big picture. He initially installed a heater bypass, as requested, without the SWG with the plan to connect it to the heater. Then he got called back to install the SWG. He forgot what he previously did and simply looked at where to cut in the SWG, glue it in, and move on. Thus the mish mash of plumbing.

The plumber should redo the plumbing from the filter output to the pool/spa valve. It should be the heater bypass with stubs looped to install the heater and the SWG put vertically on the heater output side. Also a CV should be installed on the heater output as shown in Heater Bypass - Further Reading

Tell the plumber not to block in the filter on the right side.

Mark off with tape where the heater should be placed and where your future cooler will be placed. Leave room to work around the equipment and don't let the plumber push everything tight.

Give thought to where the MasterTemp heater exhaust will be. I think the heater should be at the right end of the pad. You don't want the heater exhaust going into the cooler next to it.

Where is the gas line for the heater located?

See if you have room to move the filter over a bit and give more room between the filter and the pump. The plumber may hate you but he already has a bunch of rework so now is the time to move the filter and leave room to work around the pump and filter.

While we are looking at what was done here. On the pool return side there are two pipes after the chlorinator and one of them has a check valve. What is the pipe with the CV for? If that pipe is for your spa spillover you need a diverter valve there to adjust the flow of the spillover or turn it off.

While the plumber is doing all the rework I would have him remove the chlorinater. You don't need it and it is just something that will eventually leak.

View attachment 352434

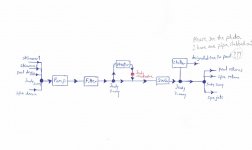

I wish I had access to a drawing or a photo showing the piping for SWG, heater, and chiller (all in the same drawing/photo) to make sure the plumber won't mess up again. I made a drawing for my pool and spa pipes at the pad but don't know if it is correct. would you please let me know whether it has any problem or not? I would like to have a correct reference since I am afraid the plumber does something wrong again, particularly since we will have both chiller and heater with SWG. In that case (if he does it wrong again), it would be very difficult to tell him to correct the plumbing for the second time.

Attachments

@ajw22 and regarding your question about the pipe with the CV: I took another photo from a different angle. The pipe marked with red color is spa return. The pipe marked with green is pool return. And the pipe marked with purple is spa jet. As you see in the photo, I have an actuated valve on spa jets and pool/spa returns. Do I still need a diverter valve instead of a check valve on the spa return?I think the plumber lost sight of the big picture. He initially installed a heater bypass, as requested, without the SWG with the plan to connect it to the heater. Then he got called back to install the SWG. He forgot what he previously did and simply looked at where to cut in the SWG, glue it in, and move on. Thus the mish mash of plumbing.

The plumber should redo the plumbing from the filter output to the pool/spa valve. It should be the heater bypass with stubs looped to install the heater and the SWG put vertically on the heater output side. Also a CV should be installed on the heater output as shown in Heater Bypass - Further Reading

Tell the plumber not to block in the filter on the right side.

Mark off with tape where the heater should be placed and where your future cooler will be placed. Leave room to work around the equipment and don't let the plumber push everything tight.

Give thought to where the MasterTemp heater exhaust will be. I think the heater should be at the right end of the pad. You don't want the heater exhaust going into the cooler next to it.

Where is the gas line for the heater located?

See if you have room to move the filter over a bit and give more room between the filter and the pump. The plumber may hate you but he already has a bunch of rework so now is the time to move the filter and leave room to work around the pump and filter.

While we are looking at what was done here. On the pool return side there are two pipes after the chlorinator and one of them has a check valve. What is the pipe with the CV for? If that pipe is for your spa spillover you need a diverter valve there to adjust the flow of the spillover or turn it off.

While the plumber is doing all the rework I would have him remove the chlorinater. You don't need it and it is just something that will eventually leak.

View attachment 352434

Attachments

- Jul 21, 2013

- 52,449

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I made a drawing for my pool and spa pipes at the pad but don't know if it is correct. would you please let me know whether it has any problem or not?

The chiller should go after the heater and before the SWG.

The chiller should be piped the same as the heater with a diverter valve for a bypass and a CV on the output.

When the heater or chiller is not installed the plumber should run the input and output pipes to the approximate pad location and loop them together. When you get the unit the loop is cut and connected.

@ajw22 and regarding your question about the pipe with the CV: I took another photo from a different angle. The pipe marked with red color is spa return. The pipe marked with green is pool return. And the pipe marked with purple is spa jet. As you see in the photo, I have an actuated valve on spa jets and pool/spa returns. Do I still need a diverter valve instead of a check valve on the spa return?

You don't need the red circled spa return but they installed it. With the IntelliCenter you will use the SPILLOVER mode to run your spillover when you want. We do not recommend continuous running of the spillover as the aeration it causes your pH to rapidly rise.

Since you have the spa return you need a diverter valve on it to adjust the flow and turn it off. You also need a CV so if you leave it on your spa does not backflow and empty when your pump is off.

@ajw22 thank you for your comments. Do you mean I need another valve in addition to the existing one marked in the picture below? Would you please clarify why diverter valve is required on the spa return? Is it needed to reduce the flow of spa to prevent rising pH due to the spillover without compromising the pool returns? If yes, that is the reason we should have the valve for spa return and not for pool returns?The chiller should go after the heater and before the SWG.

The chiller should be piped the same as the heater with a diverter valve for a bypass and a CV on the output.

When the heater or chiller is not installed the plumber should run the input and output pipes to the approximate pad location and loop them together. When you get the unit the loop is cut and connected.

You don't need the red circled spa return but they installed it. With the IntelliCenter you will use the SPILLOVER mode to run your spillover when you want. We do not recommend continuous running of the spillover as the aeration it causes your pH to rapidly rise.

Since you have the spa return you need a diverter valve on it to adjust the flow and turn it off. You also need a CV so if you leave it on your spa does not backflow and empty when your pump is off.

Attachments

- Jul 21, 2013

- 52,449

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

@ajw22 thank you for your comments. Do you mean I need another valve in addition to the existing one marked in the picture below?

Yes. You need a valve at the elbow leading into the spa return pipe above the check valve.

Would you please clarify why diverter valve is required on the spa return?

Without the valve water will always be flowing into your spa when in POOL mode and over the spillover. You will not be able to regulate how much water flows through your pool returns versus into your spa and over the spillover. Your pool returns will probably have a low flow and not be very effective.

You will also not be able to turn off the flow to the spa and stop the spillover of water. Continuous running of the spillover will cause rising pH and you will have much more acid demand to keep the pH within the 7's.

Is it needed to reduce the flow of spa to prevent rising pH due to the spillover without compromising the pool returns? If yes, that is the reason we should have the valve for spa return and not for pool returns?

You will make any flow adjustments to your pool returns by varying the RPM and flow of your VS pump. You don't need a valve on the pool return pipe to do that.

Your IntelliCenter automation will have three modes:

- POOL mode - suction comes from the skimmers and returns to the pool (and the spa depending on the setting of the new valve we are discussing)

- SPA mode - suction comes from the spa and returns to the spa

- SPILLOVER mode - suction comes from the pool and returns to the spa and then water spillsover into the pool

Thank you @ajw22 for answering my questions.Yes. You need a valve at the elbow leading into the spa return pipe above the check valve.

Without the valve water will always be flowing into your spa when in POOL mode and over the spillover. You will not be able to regulate how much water flows through your pool returns versus into your spa and over the spillover. Your pool returns will probably have a low flow and not be very effective.

You will also not be able to turn off the flow to the spa and stop the spillover of water. Continuous running of the spillover will cause rising pH and you will have much more acid demand to keep the pH within the 7's.

You will make any flow adjustments to your pool returns by varying the RPM and flow of your VS pump. You don't need a valve on the pool return pipe to do that.

Your IntelliCenter automation will have three modes:

We recommend you run your pool with the spa return off and schedule the SPILLOVER mode to run twice a day for 15 to 30 minutes to refresh the spa water. I run my spillover at 9am and 5PM for 15 minutes. That puts chlorinated fresh water in the spa for the start of the day. Then it replaces the water at 5PM for the overnight and replaces any chlorine lost during the day.

- POOL mode - suction comes from the skimmers and returns to the pool (and the spa depending on the setting of the new valve we are discussing)

- SPA mode - suction comes from the spa and returns to the spa

- SPILLOVER mode - suction comes from the pool and returns to the spa and then water spillsover into the pool

@Jimrahbe @ajw22 @mknauss I talked to my builder to fix the incorrect / mish mash of plumbing for SWGC and also to add a valve for the spa return. He is out of town and replied he would need to get the plumber at my jobsite to go over that with him.

Would you please also clarify these for me? I do appreciate it. This is our first pool and I am still learning:

Would you please also clarify these for me? I do appreciate it. This is our first pool and I am still learning:

- After filling my pool 9 days ago, the builder programmed my pool and since then the pump is running circulating water every day from 8:00 AM to 7:00 PM. I am wondering if I should stick with this schedule for now (I mean running the pump continuously every day for 11 hours)?

- I know that I shouldn't add salt for the first 30 days and should manage the pool as non-salt. My question is: should the SWGC be on while my pump is running now that I have no salt added in the pool? Here is the photo I took from my SWGC which shows it is on.

- I noticed the color of some areas in my plaster is different (it is lighter color). I talked to the builder and he said "the plaster cures for 30 days and brushing helps." However, it has been 9 days since filling the pool, and it hasn't changed (please see the photo). Wondering if the plaster sub has done something wrong?

Attachments

Last edited:

- May 3, 2014

- 58,351

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

For the first 30 days you should let the pool builder manage the pool if it is being done responsibly. The pump time is not a bad idea as it continues to clear plaster dust.

The SWCG can be on without salt in it. Though with your Intellicenter you can go in and disable the IC and turn it off.

Plaster color is variable. Darker colors show greater variation.

@tfp_fan EDIT -- Please do not post the same questions in multiple threads. It makes no sense for us to answer the same questions in multiple threads of yours.

The SWCG can be on without salt in it. Though with your Intellicenter you can go in and disable the IC and turn it off.

Plaster color is variable. Darker colors show greater variation.

@tfp_fan EDIT -- Please do not post the same questions in multiple threads. It makes no sense for us to answer the same questions in multiple threads of yours.

Last edited:

Fan,

I have a separate circuit breaker for just my SWCG, so that I can shut it off when necessary... Not sure if you do or not.

I doubt your plaster color will change much, if at all.. It tends to be what it is when done. It is almost never the same exact color everywhere.

I'd set the output % of the SWCG to zero.. Disabling the SWCG in the automation will just make the automation not know it is there, it won't keep it from powering on when the Pump/Filter relay is closed.

Thanks,

Jim R.

I have a separate circuit breaker for just my SWCG, so that I can shut it off when necessary... Not sure if you do or not.

I doubt your plaster color will change much, if at all.. It tends to be what it is when done. It is almost never the same exact color everywhere.

I'd set the output % of the SWCG to zero.. Disabling the SWCG in the automation will just make the automation not know it is there, it won't keep it from powering on when the Pump/Filter relay is closed.

Thanks,

Jim R.

@Jimrahbe thank you for your comment. I checked the circuit breakers on my panel and took a photo of it and attached here (no circuit breaker for SWG??) Should the builder have added it? Is any other thing missing?Fan,

I have a separate circuit breaker for just my SWCG, so that I can shut it off when necessary... Not sure if you do or not.

I doubt your plaster color will change much, if at all.. It tends to be what it is when done. It is almost never the same exact color everywhere.

I'd set the output % of the SWCG to zero.. Disabling the SWCG in the automation will just make the automation not know it is there, it won't keep it from powering on when the Pump/Filter relay is closed.

Thanks,

Jim R.

By the way, I found this valve left on top of the controller. Do you know what it is?

Attachments

Last edited:

Fan,

Not having a circuit breaker for the SWCG is not a problem, it is just something handy to have...

What you found is a check valve of some type.. I have not seen that specific one.. I would never add a check valve that could not be repaired. I'd use a Jandy check valve. That said, it is not installed, so I have no idea why it was left there.

Thanks,

Jim R.

Not having a circuit breaker for the SWCG is not a problem, it is just something handy to have...

What you found is a check valve of some type.. I have not seen that specific one.. I would never add a check valve that could not be repaired. I'd use a Jandy check valve. That said, it is not installed, so I have no idea why it was left there.

Thanks,

Jim R.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.