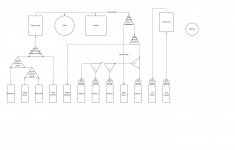

The rough plumbing is in and running to my pool pad. I'm so excited. But I'm so confused about diagraming this for optimal use. Please see the attached pictures.

#1. Do I start by just putting single or true union ball valves on each of these?

#2. or Do I create manifods / connections first...for example do ever need control skimmer 1 vs skimmer 2? should those be tied together and then have an actuator and jandy valve because I do need to control suction. Same with pool returns. Just tie them all together first with a mainfold and then jandy valve that so that pool returns are on/off ...not needing to control each one individually. Or do I?

I'm confused with flow and where and what valves go where. Any help and advice is appreciated!!!! If someone helps me figure this out I promise to send some Starbucks or amazon gift cards there way!

#1. Do I start by just putting single or true union ball valves on each of these?

#2. or Do I create manifods / connections first...for example do ever need control skimmer 1 vs skimmer 2? should those be tied together and then have an actuator and jandy valve because I do need to control suction. Same with pool returns. Just tie them all together first with a mainfold and then jandy valve that so that pool returns are on/off ...not needing to control each one individually. Or do I?

I'm confused with flow and where and what valves go where. Any help and advice is appreciated!!!! If someone helps me figure this out I promise to send some Starbucks or amazon gift cards there way!