Comments in blue...

- If i turn on the pool circuit, the spa & pool pump runs for a few seconds (maybe 30) at full RPM before it switches down to lower RPM.

That is the pump starting in priming mdoe. It is normal operation. You can set max RPM for priming if you want.

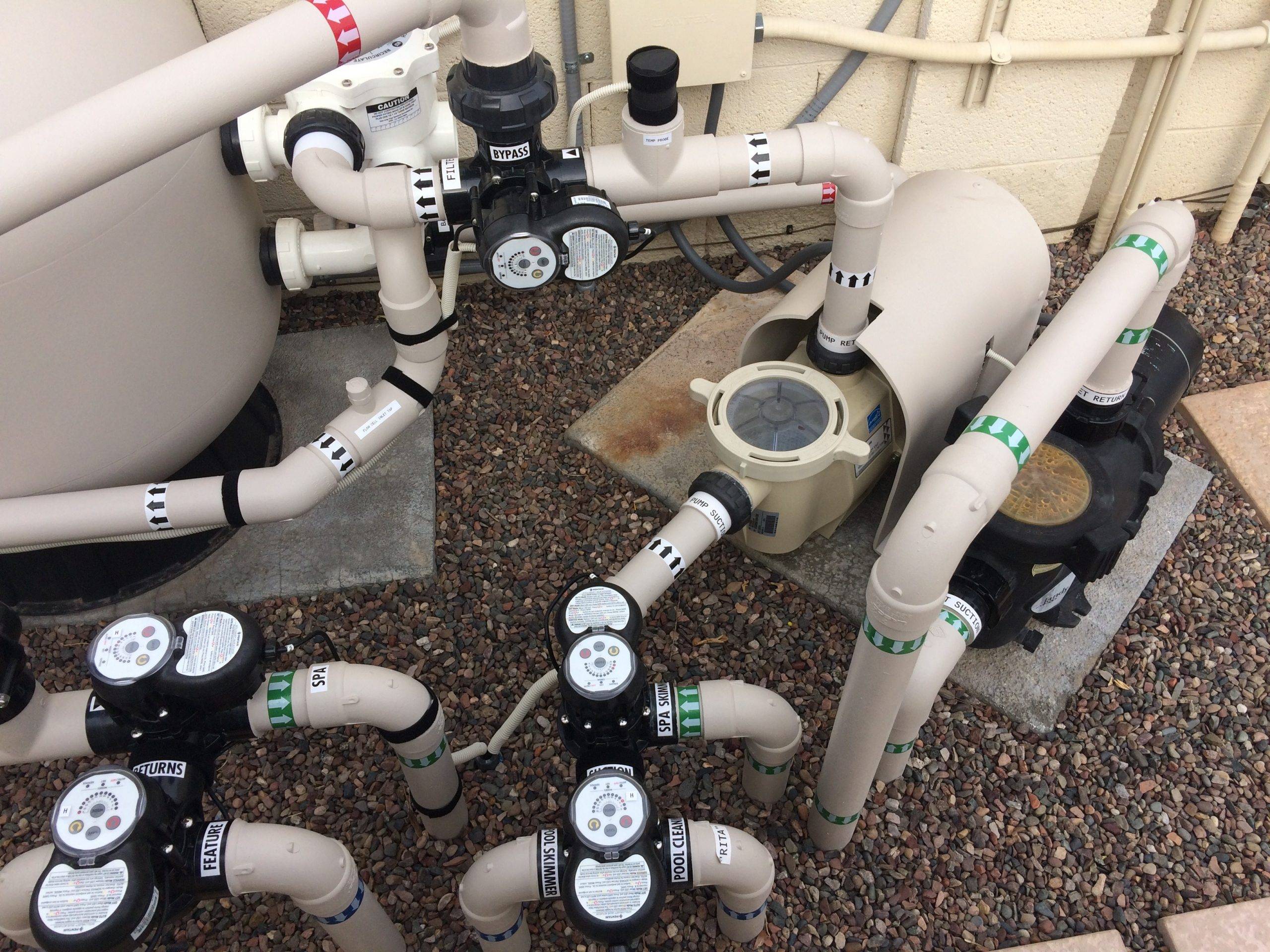

- If i turn on the SPA circuit the motorized handle in the back turns to the right and the spa&pool pump continues to run if the Spa&Pool Pump was already running.

Pump should run but both actuators should turn. Only the spa suction turning on is why your spa is partially draining.

- If the Spa&Pool pump wasn't running then it starts up at an initial high RPM before it switches down to a lower RPM.

Priming mode at pump start again.

Additionally

- If i run the SPA circuit the spa drains about halfway, and i find that enough pool water trickles over the edges that it doesn't empty after that, i assume enough water gets pushed into the pool that this is the equilibrium. That is not correct operation.

Your actuator on the return is set to be partially open so water flows to both the pool and spa. In spa mode it should turn to close the return to the pool and send all water to the spa. Your suction is pulling more water from he spa then what is being returned which is why the spa is draining.

- If i run the pool circuit after the SPA circuit it trickles over pool water a bit faster, and it refills the spa relatively quickly. I take that to mean one should always run the pool circuit then the spa circuit, then the pool circuit again. (eg run the spa circuit towards the end of the pool circuit so that the spa fills with freshly filtered pool water).

It means your spa mode is not working properly. Your spa should stay full in both modes.

So is this what is typical? You clean the spa by draining the spa and trickling in pool water over the edge? Seems like the obvious way to do it for me, who knows nothing about pools.

Fix your return actuator so it turns when in SPA mode. Your spa should always stay full.

We do not recommend having your return valve set for the spillover to run when in POOL mode. Running that way causes constant pH rise from the aeration of the spillover. You should reset the cam on the actuator to have the spa return closed when in pool mode and the pool return closed when in spa mode. Then enable your SPILLOVER mode in your ET and program the ET to run your spillover once or twice a day for 15 to 30 minutes to refresh the water in the spa.

I assume i got to run the main pool pump circuit long enough that all water filters through it. I haven't calculated the flow of the pump (kind of hard since i don't know which RPM and what that translates to in GPH). But absent of me running full on calculations (which i will do), what are the typical defaults? When i took over the pool it was setup to run 8 hours per day, and the spa ran for 30 minutes per day. Does that seem right?

If your pool is staying clean then it works for you.

To figure out how many hours you need to run your pump, you need to know how fast your pump works. You can find this here.

www.troublefreepool.com

Seems so old-school to play around with reagents and paper in todays highly digitized world...?

Digital may be precises but not accurate. There is digital test equipment in labs. They cost much more then a basic chemical test kit and digital testers need constant calibration with calibrating solutions.