It is time for me to replace my single speed pump, and many online articles say that just in one or two years the price difference will be covered by your electricity savings if you buy a VS pump. Could someone please help understand the math of this statement? For example, a single speed Hayward 3207 Tristar installed was quoted to me at $635 installed while Pentair Superflo VS was at $1200. The difference is $565. If I pay about $0.12 per Kwh and I run a single speed 3/4 hp pump for two hours a day at 1.25 kWh, it is about 30 cents per day. If I run the pump 365 days a year, it is $110 per year. Is my math wrong? Is two hours per day too little? For how long and at what HP level will I be able to run a VS pump to get the most savings?

Economics of Single vs VS pumps

- Thread starter alosito

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Nov 12, 2017

- 11,841

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Two hours a day does seem a little on the low side. But pump times are determined by what your pool needs, so there is no general formula. Maybe that's enough for your pool. But two hours a day is much less than most people run their pool pump, so the claim of ROI in one or two years is likely calculated on the average use. I run my pump about 5 hours/day in the winter, and up to 12 hours/day during pool season, because I'm driving an SWG (which needs a long pump run to generate enough chlorine) and a solar heater (which also needs a healthy amount of pumping). And a suction-side vac, which I run at night. So for someone with my use-case, I know my pump has already paid for itself.

I don't know exactly how to do the math, but keep in mind that cost per flow is not linear. Running a pump at twice the RMP will not cost just twice as much. It's exponential, so the cost goes up on a curve, way up.

Also keep in mind that the advantage of a variable speed pump might not just be for savings. I use several different speeds to optimize various processes, and I get better performance and results from my equipment because I can run several different RPMs. I've dialed in the exact RPM that my vacuum needs to cover the pool without crawling out of the water. Which is a different RPM than my solar panels want to maximize their efficiency and heat generation. My SWG needs yet another RPM. And when nothing else is running I use another RPM setting to keep the water moving. Yet another for freeze protection in the winter, and another when I want to do a quick clean of the surface with the skimmer.

For my use-case, my savings is substantial over what my electricity bill would be if my pump only ran at one speed for all those different uses.

So in addition to just figuring out the savings, think about what else you might be using that pump for in the future. Oh, and for all but the highest settings, one of the nicest features of a variable is the dB. At typical circulation speeds, the things are virtually silent. If you've ever been bothered by the sound of your pump while in or around your pool, you'll really appreciate a variable. You won't likely hear it at all.

I don't know exactly how to do the math, but keep in mind that cost per flow is not linear. Running a pump at twice the RMP will not cost just twice as much. It's exponential, so the cost goes up on a curve, way up.

Also keep in mind that the advantage of a variable speed pump might not just be for savings. I use several different speeds to optimize various processes, and I get better performance and results from my equipment because I can run several different RPMs. I've dialed in the exact RPM that my vacuum needs to cover the pool without crawling out of the water. Which is a different RPM than my solar panels want to maximize their efficiency and heat generation. My SWG needs yet another RPM. And when nothing else is running I use another RPM setting to keep the water moving. Yet another for freeze protection in the winter, and another when I want to do a quick clean of the surface with the skimmer.

For my use-case, my savings is substantial over what my electricity bill would be if my pump only ran at one speed for all those different uses.

So in addition to just figuring out the savings, think about what else you might be using that pump for in the future. Oh, and for all but the highest settings, one of the nicest features of a variable is the dB. At typical circulation speeds, the things are virtually silent. If you've ever been bothered by the sound of your pump while in or around your pool, you'll really appreciate a variable. You won't likely hear it at all.

- May 3, 2007

- 16,875

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

It is quite possible you could run only 2 hours per day. There is a run time study in my signature that indicates that most pools (>50%) can operate as low as 2 hours per day although as Dirk pointed out, most people run longer than that for other reasons than circulation. SWGs and solar heaters may require more run time. There are several factors that can come into play but for just circulation, 2 hours is more than sufficient.It is time for me to replace my single speed pump, and many online articles say that just in one or two years the price difference will be covered by your electricity savings if you buy a VS pump. Could someone please help understand the math of this statement? For example, a single speed Hayward 3207 Tristar installed was quoted to me at $635 installed while Pentair Superflo VS was at $1200. The difference is $565. If I pay about $0.12 per Kwh and I run a single speed 3/4 hp pump for two hours a day at 1.25 kWh, it is about 30 cents per day. If I run the pump 365 days a year, it is $110 per year. Is my math wrong? Is two hours per day too little? For how long and at what HP level will I be able to run a VS pump to get the most savings?

As for power usage, the TriStar 3207EE will use about 1700 watts on typical 2" plumbing and 1600 watts on typical 1.5" plumbing. I am not sure where you get the 1.25 kw but it is a bit low for that pump.

The Superflo VS will use about 330 watts at 1000 RPM. The run time could be a bit longer but to give the edge to the VS, assume it is the same run time. That is a delta of about 1370 watts or about $10 per month. To make up the cost difference of $565, that would be 56.5 months of operation (almost 5 years).

But are you sure you only pay $0.12/kwh? Being in CA, I would expect you to pay much more that that. I pay $0.30-$0.40 per kwh depending on which tier I am in. You have to use the last tier you are in rather than the first tier for this calculation.

There is a spreadsheet in my signature that allows you to do side by side comparisons of pump costs.

- May 3, 2014

- 58,345

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

alosito -- I still do not see how the motor you are speaking about is California Title 20 compliant.

Good luck.

Good luck.

- Feb 6, 2015

- 6,065

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

- Nov 12, 2017

- 11,841

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Ha, well that simplifies things! I was about to bring up the notion of a dual speed pump, but California beat me to it!

- Nov 12, 2017

- 11,841

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

A little off topic. I wasn't being totally straight when talking about how my variable saves me money over a single speed. I installed PV solar a few years ago and no longer pay for any electricity. My variable's savings was realized by requiring less panels than a single speed would have. Solar can also have a complicated ROI, but Mark's math (ROI of 5 years) reminded me that that is about the same ROI timetable for my solar system. It will pay for itself in about 5 years. After that, my electricity will really be free. (Well at least until California's PUC rolls over for PG&E and allows it to renege on all of PG&E's grandfather clauses). Point being, if you really are concerned about saving money, ya gotta look at the long haul. Saving about five bills on a pump might be worth considering in the short term, but whatever you calculate now, you must also consider what PG&E's rates will be going forward. CA and PG&E are going to make you all pay for all those fires, one way or another. Not me, but anyone not on solar will. Pony up now and save big time down the road...

Maybe its like my electric company. The actual Kw fees are relatively close to the national average. But the taxes, fees and 'power and delivery surcharge' come close to tripling that Kwh charge.

Last edited by a moderator:

I have used this calculator over and over again:

www.jandy.com

www.jandy.com

Im amazed how accurate it was. I dont know if you can plug in your numbers for the pump you are considering. My first month I ran my VS at 2750 for 12 hrs/day nearly all month, and Im sure I didnt have to. I was scared to death to see my electric bill. I was stunned when it was just over $100. Im sure that pump didnt add even $20 to my bill, and from now on it will be far less.

Pool Pump Savings Calculator | Jandy

Learn how much you can save by using a Jandy Pro Series variable-speed pump.

www.jandy.com

www.jandy.com

Im amazed how accurate it was. I dont know if you can plug in your numbers for the pump you are considering. My first month I ran my VS at 2750 for 12 hrs/day nearly all month, and Im sure I didnt have to. I was scared to death to see my electric bill. I was stunned when it was just over $100. Im sure that pump didnt add even $20 to my bill, and from now on it will be far less.

Amateurs, Ontario Hydro in Ontario Canada, is known for charging $100 a month with the power turned off at the main breaker....Maybe its like my crook electric company. The actual Kw fees are relatively close to the national average. But the taxes, fees and 'power and delivery surcharge' come close to tripling that Kwh charge.

I am on the time-of-usage plan. $0.12 is the nightly rate, and that is when I run my pump.But are you sure you only pay $0.12/kwh? Being in CA, I would expect you to pay much more that that. I pay $0.30-$0.40 per kwh depending on which tier I am in.

The answer that I got is this: "In the State of California, you are required to install two-speed or variable speed motors for anything over 1hp." The recommended Hayward 3207 Tristar is 3/4 hp so maybe that is why it is Title 20 compliant.alosito -- I still do not see how the motor you are speaking about is California Title 20 compliant.

- May 3, 2014

- 58,345

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

The motor your are showing is 3/4 hp with a SF of 1.65. That makes it a 1.25 THP motor. That is above the 1.1 THP limit for Title 20.

EDIT -- Title 20 states 3/4 THP and above. That is stricter than the Federal requirement that goes into effect next year.

EDIT -- Title 20 states 3/4 THP and above. That is stricter than the Federal requirement that goes into effect next year.

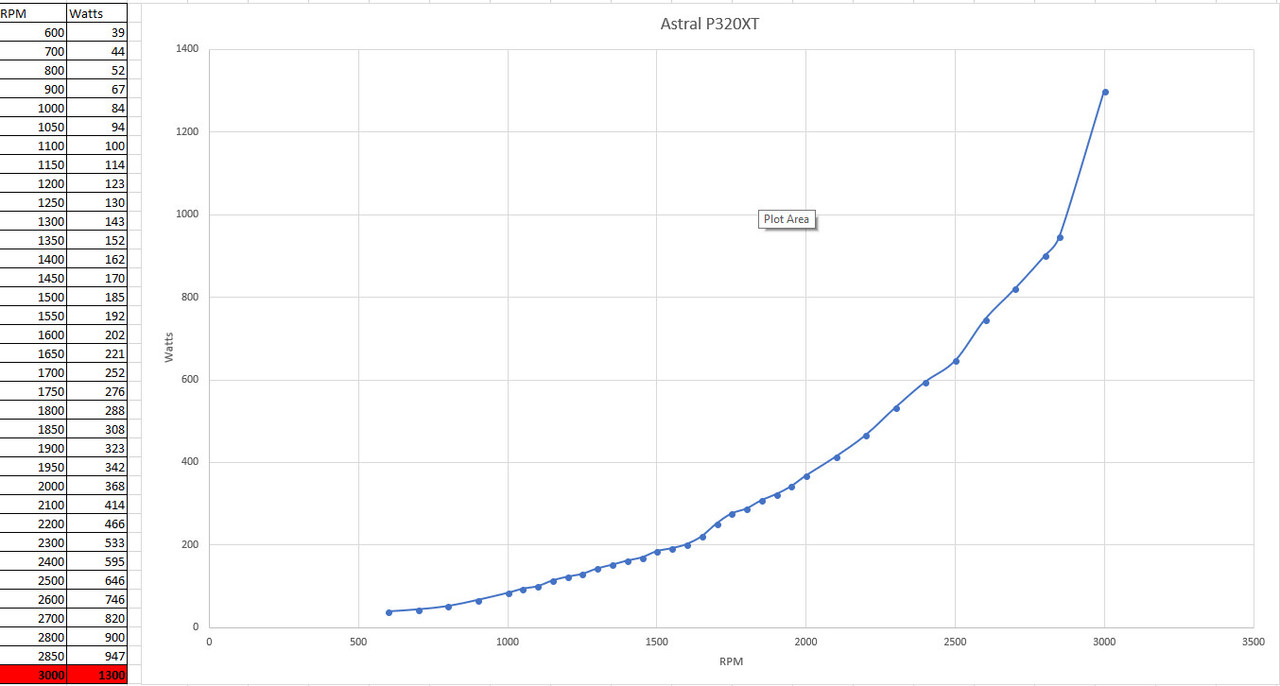

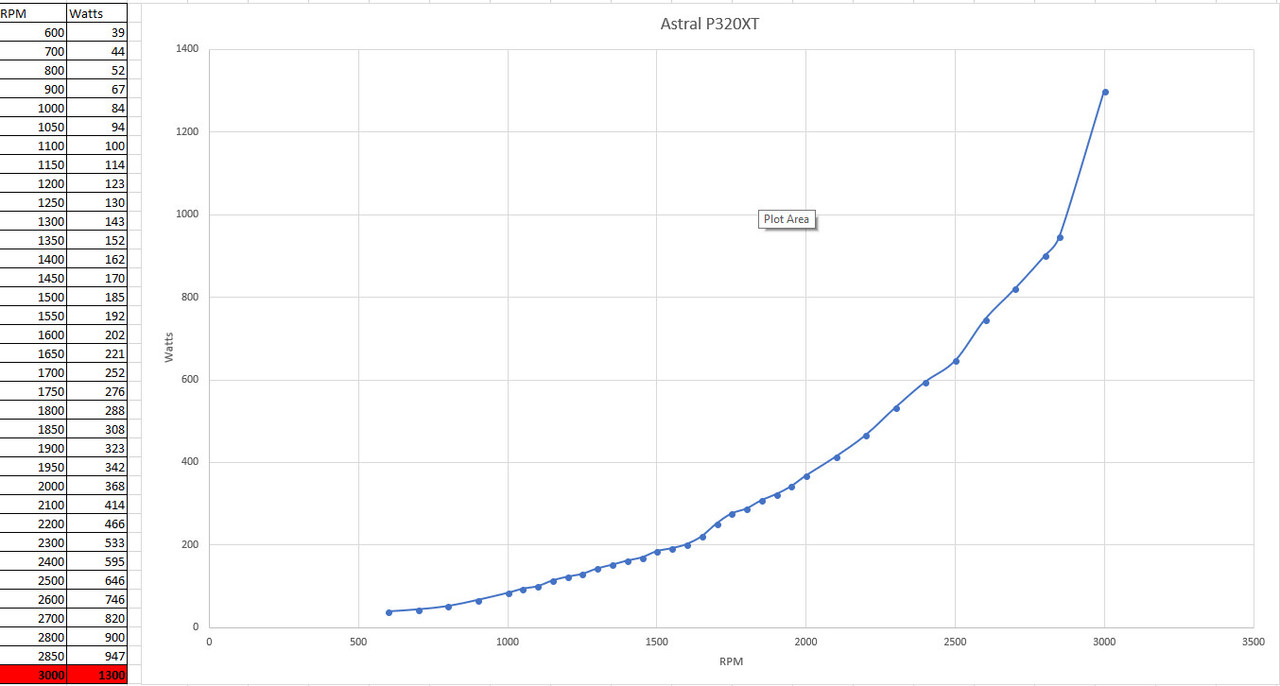

Just for everyone's benefit - Here is a graph of my pump's power consumption Vs RPM which I plotted some time ago.

You can clearly see the non linear relationship that Dirk alluded to earlier as the RPM is increased.

In my case I run my pump at 1000 RPM for day to day filtering duty which equates to around a light bulb's worth of power consumption per hour.

You can clearly see the non linear relationship that Dirk alluded to earlier as the RPM is increased.

In my case I run my pump at 1000 RPM for day to day filtering duty which equates to around a light bulb's worth of power consumption per hour.

- Nov 12, 2017

- 11,841

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I'm not sure how closely this tracks to a boat's hull (which is what I'm basing some of these "physics" on), but not only is the cost vs RPM non-linear, so is the flow. You not only pay more and more for each RPM, but you get less, too. Two times the RPM costs way more than two times, but the flow isn't even two times more. Other fluid dynamics come into play and you lose efficiency the more you push. I think that's known as the law of diminishing returns...

Hey, diminishing returns, get it?

Hey, diminishing returns, get it?

Last edited:

- May 3, 2007

- 16,875

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

RPM is linear with flow rate. So 2xRPM is 2xGPM.

But the wattage used jumps several times over the proportional RPM/flow. So it costs 20 times as much to flow 3 times the gallons. At 1200 RPMs i use 110 watts (or so, it fluctuates). At 3400 Rpms i use 2860watts.

- May 3, 2007

- 16,875

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

That is correct. My only point was that RPM and GPM are directly proportional and follow the pump affinity laws:

- GPM B = GPM A * (RPM B / RPM A)

- Head B = Head A * (RPM B / RPM A) ^ 2

- Hydraulic HP B = Hydraulic HP A * (RPM B / RPM A) ^ 3

- Nov 12, 2017

- 11,841

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Thanks for straightening that out, Mark. I know it doesn't work that way for a boat, but I didn't mean to mislead for a pool. In both cases, I was considering the entire system, not just the "engine." That said, my [admittedly uneducated] instinct about it: I am only slightly surprised to learn that about a pump, alone. But I can't help but wonder if that remains true if you consider the pump connected to a pool plumbing system and moving water into and out of a pool (which I wasn't clear about). I'd be very surprised if 2xRPM (and so 2xGPM) is actually moving 2 times the water in/out of the pool. Maybe at the low end of the graph, but at some point the efficiency must taper off.RPM is linear with flow rate. So 2xRPM is 2xGPM.

Back to the boat analogy, I could be persuaded that 2xRPM on the prop is moving 2 times the water past it, but that boat is not going to be moving twice as fast. Drag, I suspect, is the contributing culprit. Certainly that must be true of a pool plumbing system. The harder that pump pushes, the less efficient the water exchange must be.

No matter, the over-arching point is that the OP is going to see lower electricity costs and/or improved equipment performance by using a variable speed pump. It will pay for itself over time (and I still contend it offers other advantages too). Perhaps it really boils down to how much time. I'm projecting my own purchasing decisions on this thread, which are based on the fact that this is my "forever home." So no matter how long it takes to achieve ROI, I can wait it out. But if the OP knows that his stay in his home is a limited number of years, then the span of time for ROI becomes more important to consider.

There, did I weasel my way out of that sufficiently?

- May 3, 2007

- 16,875

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

As I mentioned earlier the pump affinity laws dictate that relationship. When RPM changes, the entire head curve of the pump shifts (GPM ~ RPM and Head ~ RPM^2). As long as the plumbing curve remains the same, the RPM/GPM ratio will remain a constant. However, if the plumbing curve changes with RPM, such as a check valve closing more with lower speed, then the operating point (where the plumbing curve crosses the head curve) will change as well so this relationship no longer holds. It only is applicable where the plumbing does not physically change with RPM/GPM.

You can also convince yourself by simply looking at the measured pump database: Pump Database

It combines pump measurement data from the CEC, Energy Star and APSP and shows the relationship between RPM and flow rate. Within the measurement error, RPM and GPM are directly proportional.

Also for the boat propeller, the physics are very similar. Theoretically, a 2x RPM change in propeller speed should result in a 2x water velocity exiting the propeller and the change in pressure (head) is proportional to the square of RPM. However, propeller slip comes into play so not all of the RPM angular velocity gets converted into linear speed. Also, slip should decrease with increasing RPM so in fact, the propeller becomes more efficient at higher speed and if you double the RPM, the boat should actually go more than 2x faster.

e-ribbing.com

e-ribbing.com

A centrifugal pump impeller also has slip as well but it remains constant as long as the physical characteristics of the plumbing remain the same and therefore the affinity laws apply. The boat example would also follow the affinity laws if the water hull contact remained the same with speed (e.g. hydroplane above critical speed). However, for a typical boat as speed increases, less of the water contacts the hull and the slip is reduced thereby increasing efficiency.

Other references:

www.engineeringtoolbox.com

www.engineeringtoolbox.com

You can also convince yourself by simply looking at the measured pump database: Pump Database

It combines pump measurement data from the CEC, Energy Star and APSP and shows the relationship between RPM and flow rate. Within the measurement error, RPM and GPM are directly proportional.

Also for the boat propeller, the physics are very similar. Theoretically, a 2x RPM change in propeller speed should result in a 2x water velocity exiting the propeller and the change in pressure (head) is proportional to the square of RPM. However, propeller slip comes into play so not all of the RPM angular velocity gets converted into linear speed. Also, slip should decrease with increasing RPM so in fact, the propeller becomes more efficient at higher speed and if you double the RPM, the boat should actually go more than 2x faster.

Propeller slip and its role to the boat’s performance

By Thomas P. – Cristiano SegniniAs we are trying to explain how a propeller works, in most of the cases we compare it with a screw which enters into the wood. But in reality, the propeller operates in the water and thus slides as it rotates. This means that each propeller loses a part of its...

A centrifugal pump impeller also has slip as well but it remains constant as long as the physical characteristics of the plumbing remain the same and therefore the affinity laws apply. The boat example would also follow the affinity laws if the water hull contact remained the same with speed (e.g. hydroplane above critical speed). However, for a typical boat as speed increases, less of the water contacts the hull and the slip is reduced thereby increasing efficiency.

Other references:

Pumps - Affinity Laws

Turbo machines affinity laws can be used to calculate volume capacity, head or power consumption in centrifugal pumps when changing speed or wheel diameters.

Last edited:

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.