Newbie here, have been lurking for a few weeks. Bought a house with an older pool in need of re-plastering 2 years ago, and have recently decided to attempt doing it myself. The top layer of plaster was delaminating and flaking off at an alarming rate. After draining the pool I found that a lot of the base layer of plaster sounded hollow because it wasn't properly bonded to the gunite shell. It appears that maybe someone went overboard with an acid wash on the gunite, weakening the surface drastically, as in many sections it's like a sandy soil for the 1/8" under the plaster.

Right now I'm in the process of doing the chip out, assessing the plumbing, and trying to decide what my options are. I'm thinking of trying a polished aggregate finish.

Most people likely think I'm crazy for attempting this, and I probably am, but I have a fair amount of experience with concrete and stucco. Hopefully I'll learn a lot, save some money, and end up with a pool that's no longer falling apart.

I know this is a bit of a long shot with the forum being mostly pool owners rather than builders, but does anyone know what the typical solution is for sections of gunite with a deteriorated surface? I was thinking I'd try using a commercial grade pressure washer to try and get the majority of the weak/ loose material off. I also considered grinding the top layer off, but worry about making it too smooth and not leaving enough texture for the new plaster to key in on.

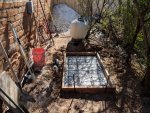

Pics of the pool at the start of draining and mid chip out included, because everyone likes pictures. I was surprised at how much worse the pool looked once it was empty.

Right now I'm in the process of doing the chip out, assessing the plumbing, and trying to decide what my options are. I'm thinking of trying a polished aggregate finish.

Most people likely think I'm crazy for attempting this, and I probably am, but I have a fair amount of experience with concrete and stucco. Hopefully I'll learn a lot, save some money, and end up with a pool that's no longer falling apart.

I know this is a bit of a long shot with the forum being mostly pool owners rather than builders, but does anyone know what the typical solution is for sections of gunite with a deteriorated surface? I was thinking I'd try using a commercial grade pressure washer to try and get the majority of the weak/ loose material off. I also considered grinding the top layer off, but worry about making it too smooth and not leaving enough texture for the new plaster to key in on.

Pics of the pool at the start of draining and mid chip out included, because everyone likes pictures. I was surprised at how much worse the pool looked once it was empty.

had at your house!

had at your house!