Hi there, TFP community! I’m building a 750 g hot tub and will be using this thread to post updates as well as ask for advice along the way. At the moment, I could really use some feedback on the pump and filter I’ve purchased. I’m concerned the pump is oversized and the filter is undersized. This will be a single pump system with a cartridge filter installed downstream of the pump. Here are some of the high level details of the design.

- 750 Gallons

- Cinder block, above ground construction

- 220 v, 50 A power

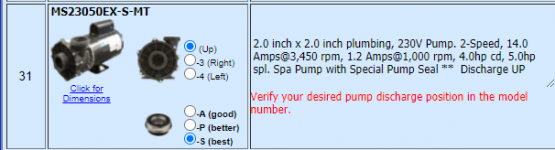

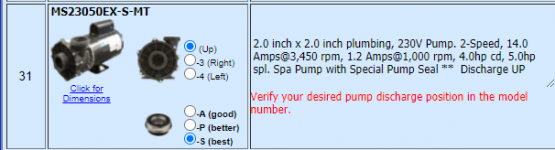

- 2 speed pump: 14 A @ 3,350 rpm, 1.2 A @ 1,000 rpm (4 hp cd, 5 hp spl)

- Pump, filter and controls within 2 ft. of tub

- 2.5 inch suction, 2 inch return lines

- 150 sq ft. filter cartridge

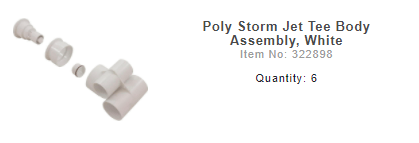

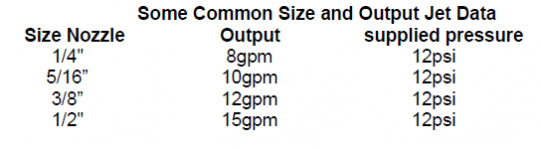

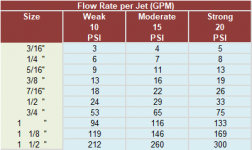

- 6 jets (2 inch water, 1.5 inch air supply lines)

- 2x 4 kw titanium heating elements (8 Kw total)

- Topside air control valve, no blower