- Apr 5, 2009

- 232

Before I lay in with the questions I'll catch everyone up. Finished the pool in 2010. Did a DIY solar panel install (34 panels) in 2013. I've been working on my outdoor bar since January 2014. This has been the biggest, most multi-faceted project yet. First was the roof; a roughly 450 sq. ft. odd shaped gable roof design shoehorned into the corner of my yard. It uses 4 outside 6x6 posts on each side (8 total) then the ridge beam is supports with two more. The ridge beam is a 5.25" x 14" x 24' parallam. The roof deck is solid pine 2x6's for looks and with a vapor barrier and metal roofing over the top.

I then embarked on the deck which is only about an inch off of the ground which was excavated down to put the top of the deck flush with grade. The deck material is Veranda (home depot) very similar to trex but cheaper.

Next step was a 36" home built brick pizza oven in the corner.

All of the pics and details can be found on my personal blog at http://n8sbar.servebeer.com/

With the oven virtually complete it's time to start the actual bar. Now for the plans:

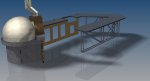

A U-shaped bar. The back side, against the fence, will be a typical BBQ island style. Steel studs build right on the deck. It will be faced with wood. The opposite side and the rest of the U shape, will be a T shape. In other words, a single 6" wall, with a 12" cantilever countertop on each side of the wall. This will be welded together out of 1.25" tube steel, .125 wall, and then painted. This will provide the bartop to put bar stools up to on one side, and another 12" cantilever to conceal my bar equipment such as kegerator, ice bin, ice machine, etc. This is the typical commercial bar type. The exposed side of this part will have corrugated metal siding with a wooden picture frame border forming squares.

All the countertops will be GFRC, pre-cast in forms, 2" thick plus an edge to conceal everything.

More pics and questions to come.

I then embarked on the deck which is only about an inch off of the ground which was excavated down to put the top of the deck flush with grade. The deck material is Veranda (home depot) very similar to trex but cheaper.

Next step was a 36" home built brick pizza oven in the corner.

All of the pics and details can be found on my personal blog at http://n8sbar.servebeer.com/

With the oven virtually complete it's time to start the actual bar. Now for the plans:

A U-shaped bar. The back side, against the fence, will be a typical BBQ island style. Steel studs build right on the deck. It will be faced with wood. The opposite side and the rest of the U shape, will be a T shape. In other words, a single 6" wall, with a 12" cantilever countertop on each side of the wall. This will be welded together out of 1.25" tube steel, .125 wall, and then painted. This will provide the bartop to put bar stools up to on one side, and another 12" cantilever to conceal my bar equipment such as kegerator, ice bin, ice machine, etc. This is the typical commercial bar type. The exposed side of this part will have corrugated metal siding with a wooden picture frame border forming squares.

All the countertops will be GFRC, pre-cast in forms, 2" thick plus an edge to conceal everything.

More pics and questions to come.