- May 3, 2007

- 16,833

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Recently, there have been a lot of questions from those living in moderate climates about using automatic freeze protection or running pumps to prevent freezing and what a pool owner should do when temperatures drop so I thought it might be useful to have a thread which dealt with the issue from both a practical and theoretical point of view.

But first a few thoughts about using pumps to prevent freezing. Running the pumps is not fool proof and power outages can obviously be a problem. Also, some pools have a lot of features and some are manually controlled so automatic freeze protection may not always be a viable solution. Plus electricity is expensive in many areas so having the pumps run all night is not always an attractive option. Given all these factors, I am not a big fan of using the pumps to prevent freezing, but there are alternatives for those that are interested.

Also, I wondered how long it would actually take for a pipe to freeze so I did some research into the physics of freezing pipes. Over the years, there have been several empirical university studies and the consensus is that for home plumbing in un-insulated spaces (e.g. attics), the "alert" temperature where pipe freezing and bursting can become a problem is below 20F. Above that temperature, freezing rarely occurs and bursting of the pipe is even rarer. But this is for small copper pipe in attics, not pool equipment so I had to look deeper.

The time it takes a pipe to freeze is dependent on several factors:

Size and dimensions of the pipe: More water in the pipe takes longer to freeze.

Pipe thermal conductivity: Copper is about 2000x more thermally conductive than is PVC.

But then there are also environmental conditions:

Air Temperature: The lower the air temperature is below freezing the faster freezing will occur.

Night Sky Exposure: Radiation losses can have a large impact on the heat loss.

Wind Speed: Wind blowing over the pipe greatly increases the heat loss of the pipe.

Location: Proximity to heat sources (e.g. side of house).

But a freezing pipe does not always result a bursting pipe. In fact, it rarely does. When a pipe freezes it freezes from the outside inwards and as the ice expands, the excess pressure is relieved through the center of the pipe until the pipe freezes solid. This alone will not burst the pipe. However, once the pipe is fully frozen and blocks the relief of pressure, the freezing ice up stream of that section of pipe may not have a path to relieve the pressure and only then does the pipe burst. This process is fairly well described in the following sources:

http://www.spokanecounty.org/data/buildingandplanning/disaster/DIS-FreezeBurstPipe.pdf

http://www.iccsafe.org/cs/PMG/Documents/DIS-FreezeBurstPipe.pdf

http://scifun.chem.wisc.edu/radio/pipefrez.html

So in order to take all these factors into account, I used standard thermal transfer equations to estimate the heat loss of a pipe when exposed to all these environmental conditions. I then ran a few experiments in my freezer to make sure the model was giving fairly accurate results, which it did.

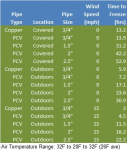

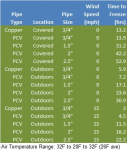

So here are a few examples:

These results assume a minimum night time temperature of 20F, starting at 32F and the time to freeze only includes the time below 32F. So the average temperature is 26F over that time frame. There is some inherent margin included in these numbers because I assumed the water temperature started out at 32F which in most cases it is higher and it ignores the latent heat within the filter water which can act like a heat source for the rest of the plumbing.

Wind has a fairly large affect but visibility to the night sky has an even larger effect. Covering the exposed equipment can reduce the heat loss considerably from both of these factors and freeze times are much much longer. So the easiest thing a pool owner can do is cover the pad equipment and plumbing with a tarp. Adding a heat source underneath the tarp or cover would add enough margin to eliminate the need for running the pump or at least provide enough backup should the automated freeze protection fail.

The heat transfer model is available here for those who are adventurous:

Hydraulics 101 - Have you lost your head?

So if you would like to be able to go without automated freeze protection OR you would just like to have an extra layer of protection, then you can follow some of the suggestions listed below. The temperature ranges and time are using the thermal loss spreadsheet above which are fairly conservative freeze estimates (i.e. assumes 15 mph winds, full sky exposure with maximum radiation losses and ignores latent heat in filters and surrounding structures).

1. Air Temp 32F->25F->32F for <10 hours. Plumbing 1" and above is safe. Tarp or drain for smaller pipes.

2. Air Temp 32F->20F->32F for <10 hours. Plumbing 1.5" and above is safe. Tarp or drain for smaller pipes.

3. Air Temp 32F->15F->32F for <10 hours. Plumbing 2" and above is safe. Tarp or drain for smaller pipes.

4. Air Temp 32F->10F->32F for <10 hours. Plumbing 2.5" and above is safe. Tarp or drain for smaller pipes.

5. Air Temp 32F->0F->32F for <10 hours. Tarp equipment and use an incandescent light bulb underneath OR use heat tape available at your local hardware store.

6. Air Temp <0F. Drain all equipment and plumbing.

Note that when air temps get close to 0F, water temps are likely to be below 40F so there is no harm in draining the equipment and letting the pool go idle since algae is fairly rare at those water temperatures. Also, opening all valves so that all ports have pressure relief to the pool will virtually eliminate any chance of the pipes bursting.

But just so you know, I do practice what I preach. My situation is #3 above and I have not bothered to use automated freeze protection for 8 winters now without incident. But I do not have any plumbing less than 2".

But first a few thoughts about using pumps to prevent freezing. Running the pumps is not fool proof and power outages can obviously be a problem. Also, some pools have a lot of features and some are manually controlled so automatic freeze protection may not always be a viable solution. Plus electricity is expensive in many areas so having the pumps run all night is not always an attractive option. Given all these factors, I am not a big fan of using the pumps to prevent freezing, but there are alternatives for those that are interested.

Also, I wondered how long it would actually take for a pipe to freeze so I did some research into the physics of freezing pipes. Over the years, there have been several empirical university studies and the consensus is that for home plumbing in un-insulated spaces (e.g. attics), the "alert" temperature where pipe freezing and bursting can become a problem is below 20F. Above that temperature, freezing rarely occurs and bursting of the pipe is even rarer. But this is for small copper pipe in attics, not pool equipment so I had to look deeper.

The time it takes a pipe to freeze is dependent on several factors:

Size and dimensions of the pipe: More water in the pipe takes longer to freeze.

Pipe thermal conductivity: Copper is about 2000x more thermally conductive than is PVC.

But then there are also environmental conditions:

Air Temperature: The lower the air temperature is below freezing the faster freezing will occur.

Night Sky Exposure: Radiation losses can have a large impact on the heat loss.

Wind Speed: Wind blowing over the pipe greatly increases the heat loss of the pipe.

Location: Proximity to heat sources (e.g. side of house).

But a freezing pipe does not always result a bursting pipe. In fact, it rarely does. When a pipe freezes it freezes from the outside inwards and as the ice expands, the excess pressure is relieved through the center of the pipe until the pipe freezes solid. This alone will not burst the pipe. However, once the pipe is fully frozen and blocks the relief of pressure, the freezing ice up stream of that section of pipe may not have a path to relieve the pressure and only then does the pipe burst. This process is fairly well described in the following sources:

http://www.spokanecounty.org/data/buildingandplanning/disaster/DIS-FreezeBurstPipe.pdf

http://www.iccsafe.org/cs/PMG/Documents/DIS-FreezeBurstPipe.pdf

http://scifun.chem.wisc.edu/radio/pipefrez.html

So in order to take all these factors into account, I used standard thermal transfer equations to estimate the heat loss of a pipe when exposed to all these environmental conditions. I then ran a few experiments in my freezer to make sure the model was giving fairly accurate results, which it did.

So here are a few examples:

These results assume a minimum night time temperature of 20F, starting at 32F and the time to freeze only includes the time below 32F. So the average temperature is 26F over that time frame. There is some inherent margin included in these numbers because I assumed the water temperature started out at 32F which in most cases it is higher and it ignores the latent heat within the filter water which can act like a heat source for the rest of the plumbing.

Wind has a fairly large affect but visibility to the night sky has an even larger effect. Covering the exposed equipment can reduce the heat loss considerably from both of these factors and freeze times are much much longer. So the easiest thing a pool owner can do is cover the pad equipment and plumbing with a tarp. Adding a heat source underneath the tarp or cover would add enough margin to eliminate the need for running the pump or at least provide enough backup should the automated freeze protection fail.

The heat transfer model is available here for those who are adventurous:

Hydraulics 101 - Have you lost your head?

So if you would like to be able to go without automated freeze protection OR you would just like to have an extra layer of protection, then you can follow some of the suggestions listed below. The temperature ranges and time are using the thermal loss spreadsheet above which are fairly conservative freeze estimates (i.e. assumes 15 mph winds, full sky exposure with maximum radiation losses and ignores latent heat in filters and surrounding structures).

1. Air Temp 32F->25F->32F for <10 hours. Plumbing 1" and above is safe. Tarp or drain for smaller pipes.

2. Air Temp 32F->20F->32F for <10 hours. Plumbing 1.5" and above is safe. Tarp or drain for smaller pipes.

3. Air Temp 32F->15F->32F for <10 hours. Plumbing 2" and above is safe. Tarp or drain for smaller pipes.

4. Air Temp 32F->10F->32F for <10 hours. Plumbing 2.5" and above is safe. Tarp or drain for smaller pipes.

5. Air Temp 32F->0F->32F for <10 hours. Tarp equipment and use an incandescent light bulb underneath OR use heat tape available at your local hardware store.

6. Air Temp <0F. Drain all equipment and plumbing.

Note that when air temps get close to 0F, water temps are likely to be below 40F so there is no harm in draining the equipment and letting the pool go idle since algae is fairly rare at those water temperatures. Also, opening all valves so that all ports have pressure relief to the pool will virtually eliminate any chance of the pipes bursting.

But just so you know, I do practice what I preach. My situation is #3 above and I have not bothered to use automated freeze protection for 8 winters now without incident. But I do not have any plumbing less than 2".

Last edited:

X 2

X 2