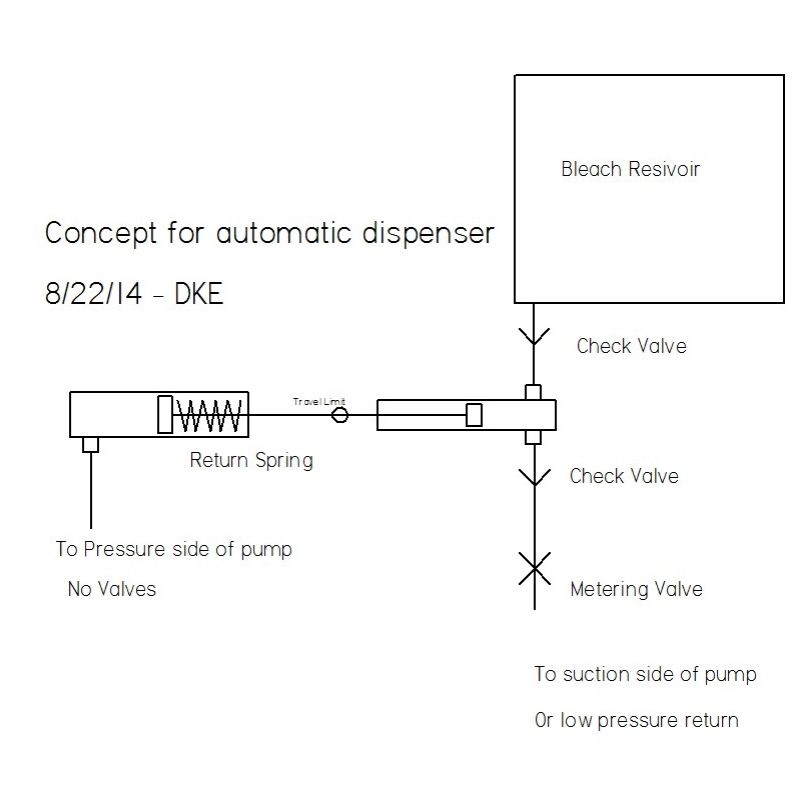

So, I've been chewing on ideas of reducing my daily maintenance effort... SWG are interesting, not entirely sure I understand how the liquidator works yet (suction side of filter pump plus a metering valve? Seems a recipe for inconsistent delivery) and then you have metering pumps (mostly Stenners, it seems). At the moment I'm having a hard time swallowing the cost for any of them. Commercial liquid chlorine dispensing seems a bit too expensive compared to SWG. Fairly close to the same price, but I still have to buy and carry the chlorine. A SWG is attractive, but I'f I'm investing that much (and dealing with salting the water), it really needs to be part of a whole plan to renovate the pad. So I'm considering low-cost DIY options.

Hoping it doesn't turn out like this:

It seems a lot of people are doing at least some amount of DIY with the Stenner pumps anyway, different timers and control schemes and different tank arrangements seem to be common. Is anyone doing anything interesting with different pumps?

I see this one from McMaster-Carr http://www.mcmaster.com/#43045k51/=tdlzjx for about $150 does almost 20 gallons a day (80 gallon a day version available for about the same price)

Then I was poking around e-bay and tripped on these: http://www.ebay.com/itm/Peristaltic.../291109659872?pt=BI_Pumps&hash=item43c77ce4e0 Rated 100mL a minute. If I did the conversion right, that's about 38 gallons a day. Best part is they're available for less than $10 shipped.

No word on chemical compatibility, but I'm thinking at that price I could probably afford to change the tubing out for something bleach-compatible.

Any thoughts?

Hoping it doesn't turn out like this:

It seems a lot of people are doing at least some amount of DIY with the Stenner pumps anyway, different timers and control schemes and different tank arrangements seem to be common. Is anyone doing anything interesting with different pumps?

I see this one from McMaster-Carr http://www.mcmaster.com/#43045k51/=tdlzjx for about $150 does almost 20 gallons a day (80 gallon a day version available for about the same price)

Then I was poking around e-bay and tripped on these: http://www.ebay.com/itm/Peristaltic.../291109659872?pt=BI_Pumps&hash=item43c77ce4e0 Rated 100mL a minute. If I did the conversion right, that's about 38 gallons a day. Best part is they're available for less than $10 shipped.

No word on chemical compatibility, but I'm thinking at that price I could probably afford to change the tubing out for something bleach-compatible.

Any thoughts?

Maybe I'll just stop by walmart for a couple more bottles of bleach.

Maybe I'll just stop by walmart for a couple more bottles of bleach.