This might be a little unorthodox and the post might be a little too long, so please bear with me

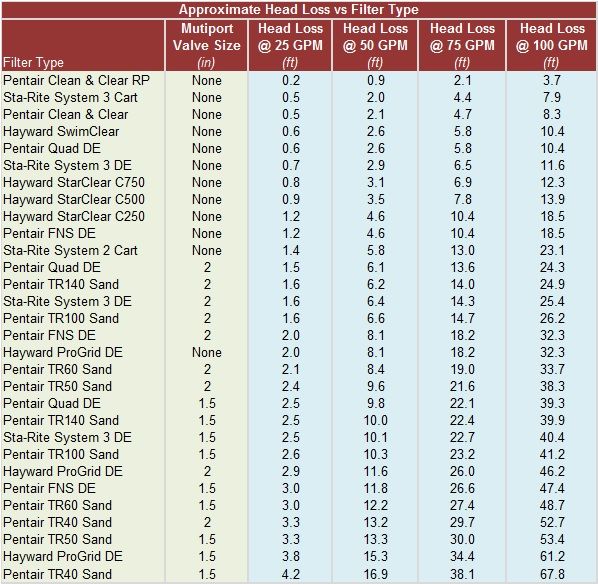

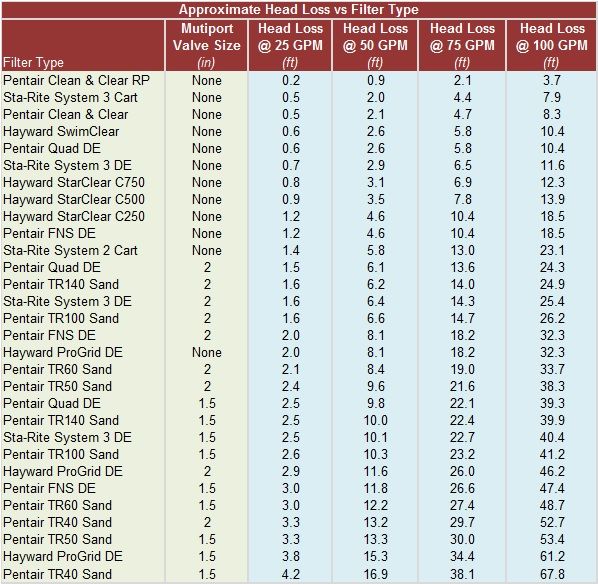

I have a Hayward Pro-Grid DE4820 filter with a 1.5” multiport valve, which is second most restrictive combo according to a table from mas985’s outstanding “Hydraulics 101” post:

Hydraulics 101 - Have you lost your head?

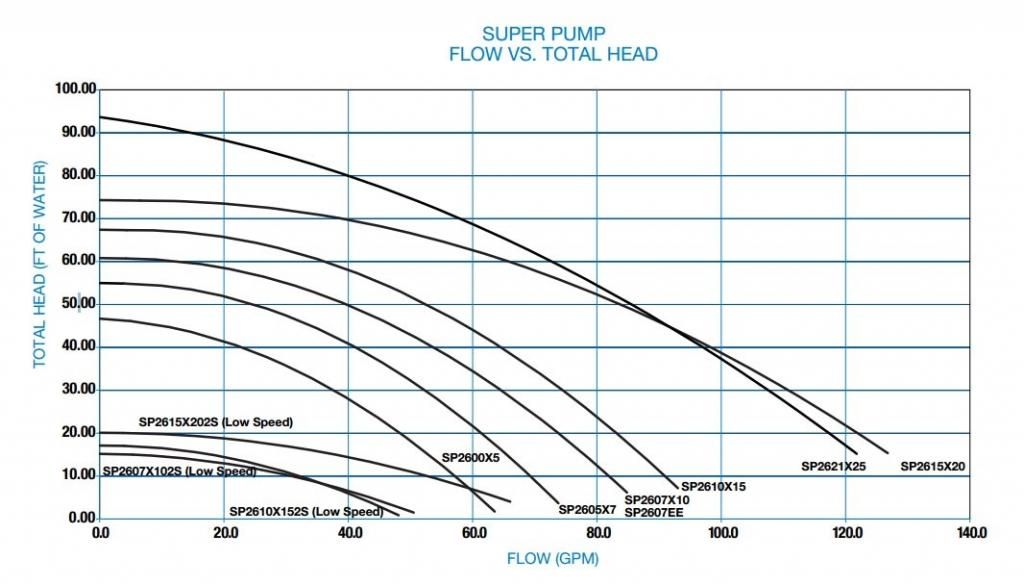

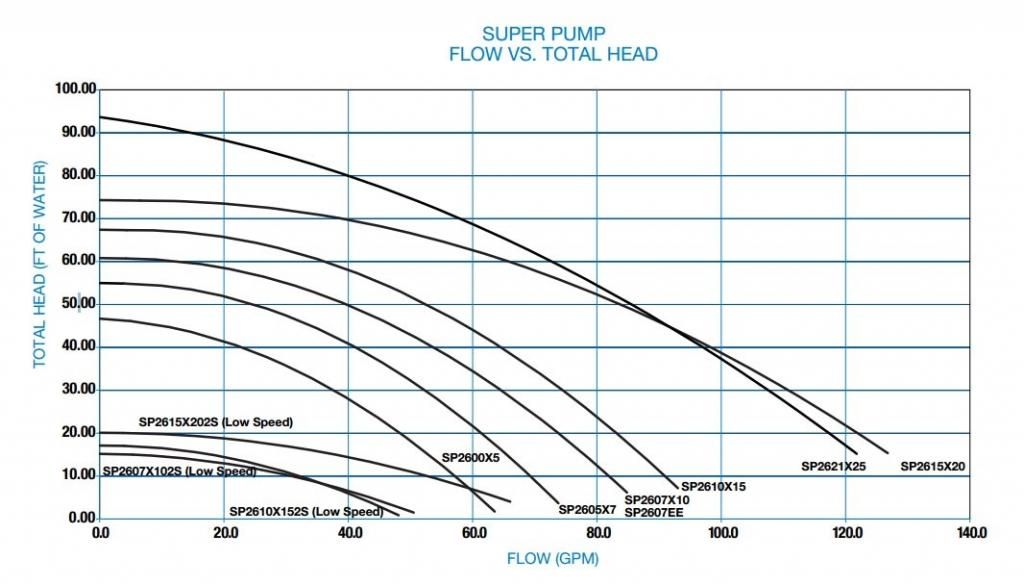

I also have a 2 speed SuperPump - I replaced the original motor to a similar 2 speed. Here is the flow vs. head chart for my pump on high speed (curve SP2607x10):

After a few weeks of filtering, my system numbers are like these (high speed):

Pressure gauge on the filter: 11psi

Vacuum gauge at the pump wet end: 6”Hg

Head (calculated): ~43’

Flow rate according to the chart above: ~50GPM

Assumed flow rate on low: 20-25GPM (?)

Flow rate from the flowmeter is about the same 50GPM, so it seems that the numbers I have are right.

I can get a maximum flow rate of about 60 GPM, but that’s freshly coated, with all return jet fittings removed, so it’s not realistic. Looking at the filter efficiency table, it seems that for 50 GPM the head loss for my filter/multiport combo is 15.3’ or about 35% of the overall system head. The head loss for filter without a multiport for 50GPM is about 8.1 or almost half of the loss of the combo! So the multiport is pretty much as restrictive as the filter itself.

What I can’t calculate is what my flow rate would with the numbers mentioned above if I remove the multiport out of the picture. I can’t simply deduct 7.2’ of the head loss for multiport at 50 GPM from the overall system head loss. Reducing the head loss will increase the flow rate which will in turn raise the head loss for the rest of the system. I would think I could see a jump in the flow rate to about 65GPM, but it’s a guess and if someone could help me with more intelligent number I would appreciate it!

Here is a little bit more info why I’m curious about it. I’m a 4th year pool owner. After reading pretty much the entire TFP site over the winter of 2010-2011 I was ready for the pool season and it was a breeze! But I like to tinker with things so I replaced an aging motor on the original superpump with a 2 speed. Since then I seem to have some problems with low speed filtering that manifest themselves as green algae spots here and there and occasional haziness. With adequate chlorine levels for given CYA none the less.

For a while I thought it was a solar cover that got waterlogged and that stays in the pool 5 days out of 7, but now more and more I believe it was lack of proper circulation/mixing. Especially since I made a mistake of short filter times and removal of all the return jet fittings. I thought I’d help the flow rate since the cover was constantly on and no skimming was taking place anyway. It did help with the flow rate , but it severely impeded the mixing.

The filter time is increased now, ½” fish eye fittings are on, but the green spots here and there still tell me that I could use better mixing. Even if for some reason that’s not the case, better flow rate is good any way.

Currently I’m hard-plumbing waste port of my multiport to a drain pipe so I could do backwashing without using flexible hose that is PIA. I’m also hard-plumbing drain port of my filter to the same drain pipe with a ball valve – this will allow me to rinse the DE grids in-place during maintenance and drain the water out of the filter at the end of the season.

While I was planning this work I start to realize that waste port on my multiport might not as important anymore .With this plumbing in place and with some additional full port ball valves in front of the filter I can get rid of the multiport and still perform all the basic operations required for DE filter with some small exceptions:

- The waste function would send the water into the filter, bypassing the grids and to the drain port. Should be ok, I think.

- Rinse operation would not work w/o additional T at the filter output. But looking thru posts on the forum, lack of this operation doesn't seem to be a big deal.

I have a inline 3” tablet feeder (Rainbow 320) that was working very well for my on high speed. My starting CYA is low and my swimming season is short, so I could use some tables for quite a while without dramatic CYA raise. But on the low speed there is not enough flow thru the feeder even with top feeding position, dosing valve removed completely and tubing swapped for a large diameter. I’d like to use the feeder so maybe with increased flow I would be able to do it again.

Thanks for reading!

I have a Hayward Pro-Grid DE4820 filter with a 1.5” multiport valve, which is second most restrictive combo according to a table from mas985’s outstanding “Hydraulics 101” post:

Hydraulics 101 - Have you lost your head?

I also have a 2 speed SuperPump - I replaced the original motor to a similar 2 speed. Here is the flow vs. head chart for my pump on high speed (curve SP2607x10):

After a few weeks of filtering, my system numbers are like these (high speed):

Pressure gauge on the filter: 11psi

Vacuum gauge at the pump wet end: 6”Hg

Head (calculated): ~43’

Flow rate according to the chart above: ~50GPM

Assumed flow rate on low: 20-25GPM (?)

Flow rate from the flowmeter is about the same 50GPM, so it seems that the numbers I have are right.

I can get a maximum flow rate of about 60 GPM, but that’s freshly coated, with all return jet fittings removed, so it’s not realistic. Looking at the filter efficiency table, it seems that for 50 GPM the head loss for my filter/multiport combo is 15.3’ or about 35% of the overall system head. The head loss for filter without a multiport for 50GPM is about 8.1 or almost half of the loss of the combo! So the multiport is pretty much as restrictive as the filter itself.

What I can’t calculate is what my flow rate would with the numbers mentioned above if I remove the multiport out of the picture. I can’t simply deduct 7.2’ of the head loss for multiport at 50 GPM from the overall system head loss. Reducing the head loss will increase the flow rate which will in turn raise the head loss for the rest of the system. I would think I could see a jump in the flow rate to about 65GPM, but it’s a guess and if someone could help me with more intelligent number I would appreciate it!

Here is a little bit more info why I’m curious about it. I’m a 4th year pool owner. After reading pretty much the entire TFP site over the winter of 2010-2011 I was ready for the pool season and it was a breeze! But I like to tinker with things so I replaced an aging motor on the original superpump with a 2 speed. Since then I seem to have some problems with low speed filtering that manifest themselves as green algae spots here and there and occasional haziness. With adequate chlorine levels for given CYA none the less.

For a while I thought it was a solar cover that got waterlogged and that stays in the pool 5 days out of 7, but now more and more I believe it was lack of proper circulation/mixing. Especially since I made a mistake of short filter times and removal of all the return jet fittings. I thought I’d help the flow rate since the cover was constantly on and no skimming was taking place anyway. It did help with the flow rate , but it severely impeded the mixing.

The filter time is increased now, ½” fish eye fittings are on, but the green spots here and there still tell me that I could use better mixing. Even if for some reason that’s not the case, better flow rate is good any way.

Currently I’m hard-plumbing waste port of my multiport to a drain pipe so I could do backwashing without using flexible hose that is PIA. I’m also hard-plumbing drain port of my filter to the same drain pipe with a ball valve – this will allow me to rinse the DE grids in-place during maintenance and drain the water out of the filter at the end of the season.

While I was planning this work I start to realize that waste port on my multiport might not as important anymore .With this plumbing in place and with some additional full port ball valves in front of the filter I can get rid of the multiport and still perform all the basic operations required for DE filter with some small exceptions:

- The waste function would send the water into the filter, bypassing the grids and to the drain port. Should be ok, I think.

- Rinse operation would not work w/o additional T at the filter output. But looking thru posts on the forum, lack of this operation doesn't seem to be a big deal.

I have a inline 3” tablet feeder (Rainbow 320) that was working very well for my on high speed. My starting CYA is low and my swimming season is short, so I could use some tables for quite a while without dramatic CYA raise. But on the low speed there is not enough flow thru the feeder even with top feeding position, dosing valve removed completely and tubing swapped for a large diameter. I’d like to use the feeder so maybe with increased flow I would be able to do it again.

Thanks for reading!

Last edited: