I have just finished hooking up my Liquidator, and before I start iy up, is there any thing I need to check for, any suggestions, any insight from anyone before I get it going?

Liquidator start-up, NO FLOW!!!!! help

- Thread starter Poolidiot

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: Liquidator start-up

Make sure you didnt put the suction fitting on the pool *pump* drain, that is the pump itself. I did this with mine and water came into the tank not go out. You have to put the fitting in the basket drain if you have one. Remove the basket drain pug and get a nylon 1/4" barb fitting, or of course just use the clamps and saddle that comes with it in the suction side.

Hope this helps

Brian

Make sure you didnt put the suction fitting on the pool *pump* drain, that is the pump itself. I did this with mine and water came into the tank not go out. You have to put the fitting in the basket drain if you have one. Remove the basket drain pug and get a nylon 1/4" barb fitting, or of course just use the clamps and saddle that comes with it in the suction side.

Hope this helps

Brian

Re: Liquidator start-up

Ok, i guess I am a dummy, I am not following you, and My LQ tank did fill but I can not get it to come out. :?

What I have is, from the LQ I come out to the flow adjustment valve, then from the flow adjustment valve I go to the flow indicator, from the flow indicator I go to the chack valve, from the check valve I connect to my pipe between my skimmer and the pump. Is this correct? But I do not get any flow out of the LQ

Ok, i guess I am a dummy, I am not following you, and My LQ tank did fill but I can not get it to come out. :?

What I have is, from the LQ I come out to the flow adjustment valve, then from the flow adjustment valve I go to the flow indicator, from the flow indicator I go to the chack valve, from the check valve I connect to my pipe between my skimmer and the pump. Is this correct? But I do not get any flow out of the LQ

Re: Liquidator start-up

You dont need the check valve on the output side, that maybe why you arent getting aything out of it. I didnt put mine in the output side only the input side has a check valve. Also make sure the check valve arrow is pointing towards the pipe, not the LQ.

The way I checked so see if I was going to get suction is, when the LQ was filling with water and wasnt full to the output float, I lifted up the float for the output side. When you do this if there isnt any water up to that output side it should suck air into the line.

Can you take a pciture of the ouptut side and post it, that may help.

Brian

You dont need the check valve on the output side, that maybe why you arent getting aything out of it. I didnt put mine in the output side only the input side has a check valve. Also make sure the check valve arrow is pointing towards the pipe, not the LQ.

The way I checked so see if I was going to get suction is, when the LQ was filling with water and wasnt full to the output float, I lifted up the float for the output side. When you do this if there isnt any water up to that output side it should suck air into the line.

Can you take a pciture of the ouptut side and post it, that may help.

Brian

Re: Liquidator start-up

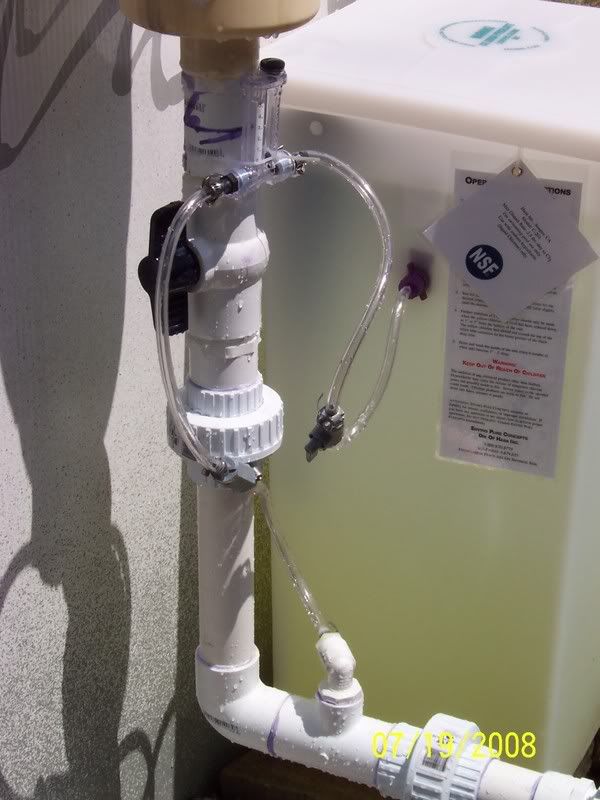

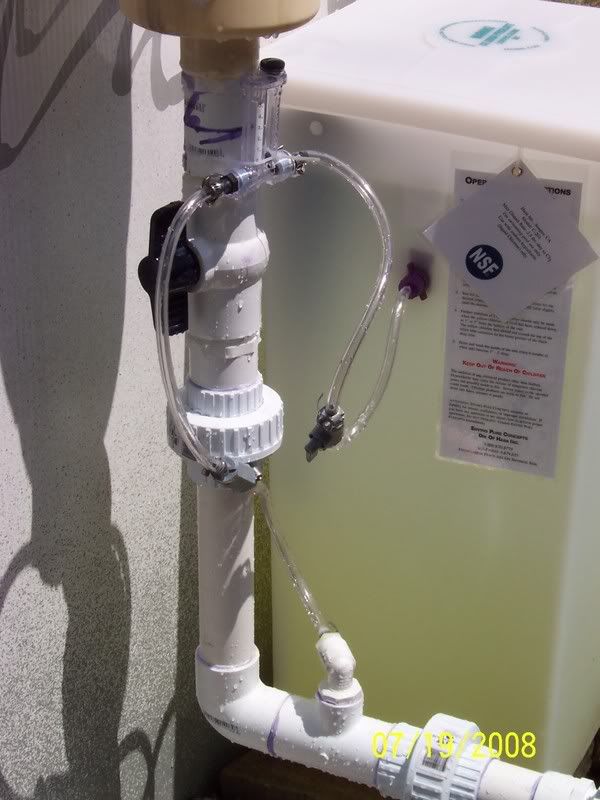

Maybe these pics will post, here is my set up for the outlet side, and I get NO flow.

Do not look at the trash Never clean up till the job is done!!!

Never clean up till the job is done!!!

Instructions says to make sure the arrow one the adjustable flow valve faces away from the Liquidator, Flow valve does not have an arrow on it.

Maybe these pics will post, here is my set up for the outlet side, and I get NO flow.

Do not look at the trash

Instructions says to make sure the arrow one the adjustable flow valve faces away from the Liquidator, Flow valve does not have an arrow on it.

Rabbit

0

- Jul 12, 2008

- 74

Try to swap your check valves, it may be that you have a bad one. It appears you have a nice setup. Love the way you connected the suction line. The direction of the control valve won't have any impact of any significance on the flow rates. The instruction on the side hanging off shows what direction the control valve should face however.

Well I removed the check valve on the output side and I now get flow. Duraliegh this may be a question you might could find an answer out for me/us. Why do they supply and tell you to install a check valve on the output side , when putting one in makes it NOT work and it works with out one?

Rabbit

0

- Jul 12, 2008

- 74

Poolidiot said:Well I removed the check valve on the output side and I now get flow. Duraliegh this may be a question you might could find an answer out for me/us. Why do they supply and tell you to install a check valve on the output side , when putting one in makes it NOT work and it works with out one?

I suspect you may have a defective one. It works with or without it, you just get a bit more flow without it. Based on all the other work you've done I doubt you installed it backwards

kmb997

0

Poolidiot, can you tell me the sizes of that tee and what kind of fittings you have coming out of it?

Thanks

Thanks

kmb997 said:Poolidiot, can you tell me the sizes of that tee and what kind of fittings you have coming out of it?

Thanks

The "T" is a 1 1/2" x 1 1/2" x 3/4"(could not find 1 1/2" x 1 1/2" x 1/2"), then I had to get a 3/4" slip reducer down to 1/2" threads. then I put a 1/2" 90 one end with male threads and the other has female threads. Then I screwed in a 1/2" thread x 1/4" barb fitting.Hope this helps.

The check valves that HASA puts in the LQ are dumb, IMO. They are set to resist forward flow up to about 1-2psi. This is so they can operate in any position and don't rely on gravity for their "checking" capability.

However, there is no need for them to have that much resistance and, in some cases, supply so much resistance the LQ cannot overcome them and operate.

I suggest the output side of the LQ not have a check valve installed although there is a circumstance where it is necessary and I can't, for the life of me, remember that circumstance. Mine is removed.

However, there is no need for them to have that much resistance and, in some cases, supply so much resistance the LQ cannot overcome them and operate.

I suggest the output side of the LQ not have a check valve installed although there is a circumstance where it is necessary and I can't, for the life of me, remember that circumstance. Mine is removed.

Rabbit

0

- Jul 12, 2008

- 74

If the water level of your pool is above the LQ, then in theory the water from the pool is going to drain down in to the outlet of the LQ and overflow the tank. The inlet side shuts off when the tank gets too full, the outlet side turns on when the tank is full enough. So in the case of an above ground pool the water might (and should) back flow in the LQ causing the tank to overflow.

I would suggest a better check valve from US Plastics.

One of these Check valves

and two of these

Fittings

Just get the fittings to match the NPT pipe size of the valves.

The check valves mentioned can be disassembled and the springs altered (or even removed) if needed to adjust the pressure setting.

I would suggest a better check valve from US Plastics.

One of these Check valves

and two of these

Fittings

Just get the fittings to match the NPT pipe size of the valves.

The check valves mentioned can be disassembled and the springs altered (or even removed) if needed to adjust the pressure setting.

Rabbit said:So in the case of an above ground pool the water might (and should) back flow in the LQ causing the tank to overflow.

Mine is an ABG pool, so you are saying I am screwed with out one?

Rabbit said:The check valves mentioned can be disassembled and the springs altered (or even removed) if needed to adjust the pressure setting.

I leave for vacation Tuesday morning, thats all I need for my LQ to over flow while I am gone. You say I can take the valve apart that came with the LQ and remove the spring and it will work? Are they made where you can take them apart?

As long as your pump is running, (I usually keep mine running 24/7 until today) no you arent screwed.

If it shuts off yes, your screwed, it will backflow into the LQ. I just tested mine with the valve full open and in about 1 hr the level in the LQ went up about 2" . I have a 24 ft round above ground pool.

Looks like I will be adding my check valve in tomorrow and hopefully mine is ok.

Hope this helps

Brian

If it shuts off yes, your screwed, it will backflow into the LQ. I just tested mine with the valve full open and in about 1 hr the level in the LQ went up about 2" . I have a 24 ft round above ground pool.

Looks like I will be adding my check valve in tomorrow and hopefully mine is ok.

Hope this helps

Brian

Rabbit

0

- Jul 12, 2008

- 74

Poolidiot said:Rabbit said:So in the case of an above ground pool the water might (and should) back flow in the LQ causing the tank to overflow.

Mine is an ABG pool, so you are saying I am screwed with out one?

Well, logic tells me it should drain back. There are always exceptions however where the water pressures in various components might cause sort of a vapor (or in this case water) lock that prevents the reverse flow because of pressure differentials.

Bottom line, keep an eye on it. Your not screwed you may just need to get a different check valve. So far I'm loving my LQ and don't regret the purchase. Was it a bit trying at first, sure thing. Just remember, even the best of wines can give you a headache

Rabbit

0

- Jul 12, 2008

- 74

Poolidiot said:Rabbit said:The check valves mentioned can be disassembled and the springs altered (or even removed) if needed to adjust the pressure setting.

I leave for vacation Tuesday morning, thats all I need for my LQ to over flow while I am gone. You say I can take the valve apart that came with the LQ and remove the spring and it will work? Are they made where you can take them apart?

The one I suggest to replace the LQ one you can take apart. The one that came with it...no such luck. I tried

Well I just went out and installed my check valve in the output side and it dropped the flowmeter down to about 2-21/2 is all I can get out of it now.

I am going to still try it at the low level and just have the 3/8" barbs and, other things to up the flow, on hand, just in case it doesnt give me enough chlorine.

It seems that when the LQ ran without the check valve in the output side, and with the flow at 3 me going from 6.5ppm CL in my pool amd running overnight, and then in the morining the CL level was up to 13 ppm even at a low flow rate I should still be ok.

Maybe the LQ needs the larger dia. hose and fittings for some above ground pools, and most in ground pools dont have a problem because of no gravity and no back pressure on the output line. Just my opinion though.

Brian

I am going to still try it at the low level and just have the 3/8" barbs and, other things to up the flow, on hand, just in case it doesnt give me enough chlorine.

It seems that when the LQ ran without the check valve in the output side, and with the flow at 3 me going from 6.5ppm CL in my pool amd running overnight, and then in the morining the CL level was up to 13 ppm even at a low flow rate I should still be ok.

Maybe the LQ needs the larger dia. hose and fittings for some above ground pools, and most in ground pools dont have a problem because of no gravity and no back pressure on the output line. Just my opinion though.

Brian

keithw

0

Your problem is that you don't have a long enough suction supply line. This issue is common with the LQ and above ground pools. It is addressed in a different post somewhere on this site. Most inground pools have 10-20ft supply lines and that allows the line to build up adequate suction near the pump inlet. You have two easy solutions: increase the length of the supply line or restrict flow through the skimmer line to build up more head. I see that you have a shut off valve on the supply line closer to the skimmer that the LQ connection. Try closing that valve off partially until you build up enough flow. Doing this might even benefit your pump because they are optimized to deal with a specific amount of water resistance. Haas also recommend that the LQ connection be right next to the pump. As a test, you might try to connect the LQ into the pump drain plug as well.

You need the check valves if the float holes on on your LQ are below water level. If they are above water level then you can eliminate them for increased flow.

You need the check valves if the float holes on on your LQ are below water level. If they are above water level then you can eliminate them for increased flow.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.

Similar threads

- Replies

- 12

- Views

- 108

- Replies

- 189

- Views

- 3K

- Replies

- 3

- Views

- 92

- Replies

- 8

- Views

- 74