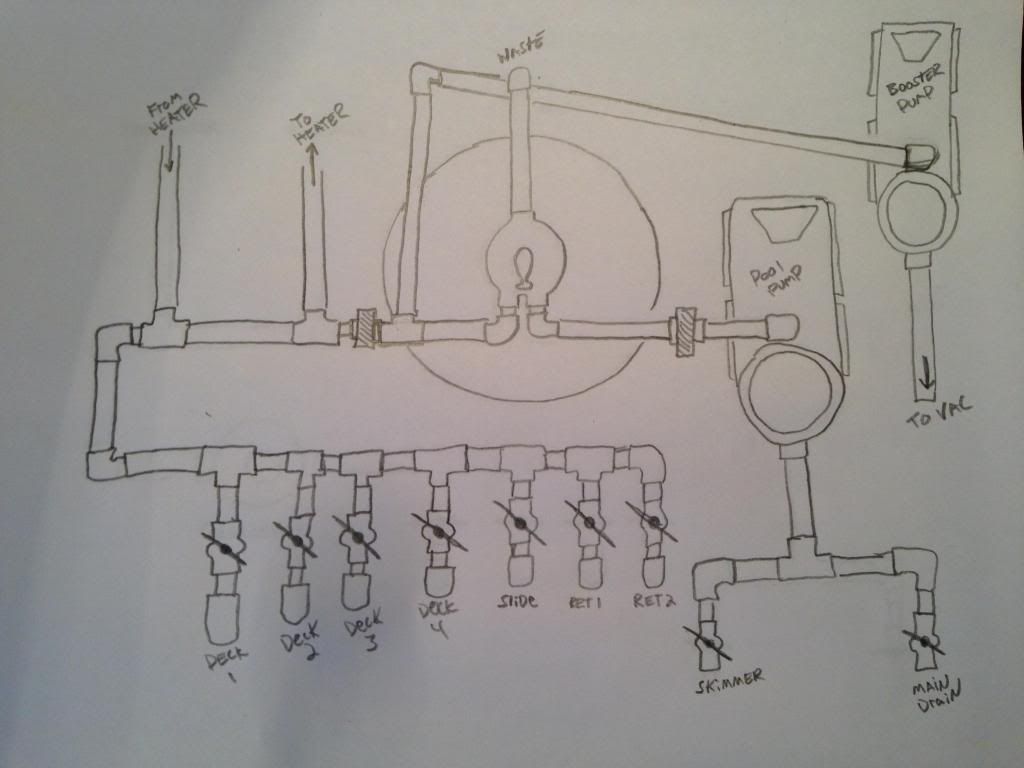

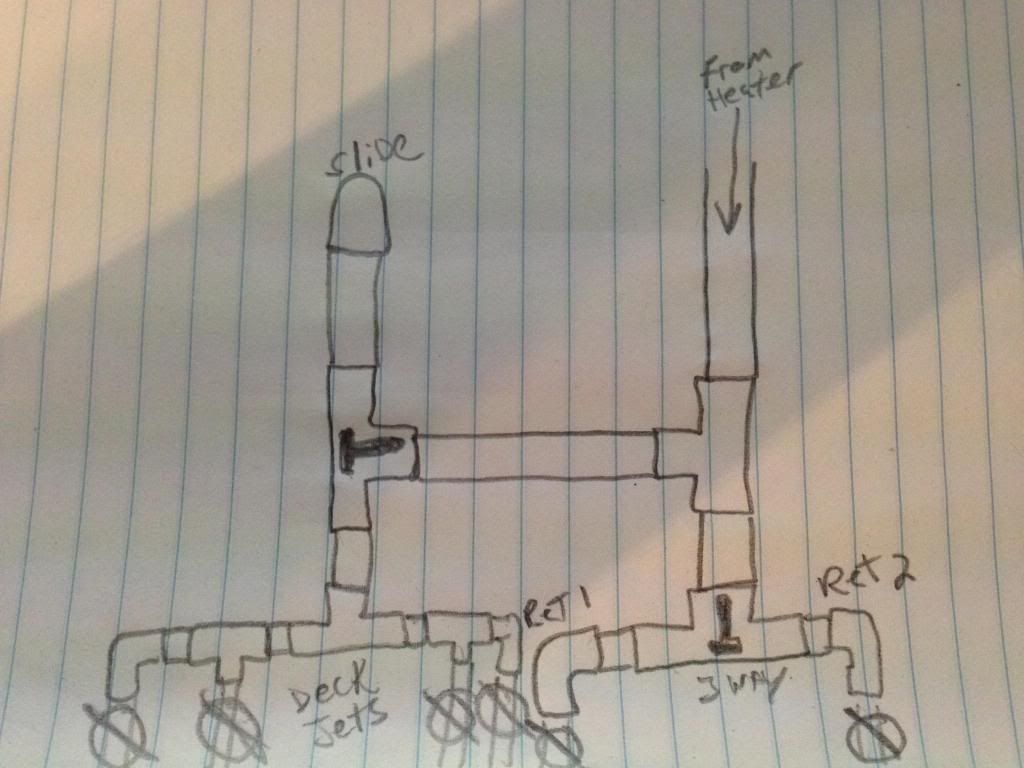

Hi folks... I am waiting on my valves and jets to show up this week, and as long as the cold stays away I want to start my install this weekend. I am going to replace all my ball valves, and remove the Chlorinator as well as add a valve to each return. I plan on running the deck jet manifold between the filter and heater (is this OK) this is where my sliding board is plumbed (will include it in the deck jet manifold for a cleaner appearance). Also I don't have any check valves, is this needed? I haven't had any since the pool was built, and don't know if its needed. I may add a flow meter (if not this time, I will this summer) if I do what is the best location for that.

My plumbing is all 1.5. I plan to make the manifold for the deck jets out of 1.5 and the runs will be 1.5 all the way to the wall and then 3/4 up to the surface to the jets.

My pump is a 3/4 HP pump

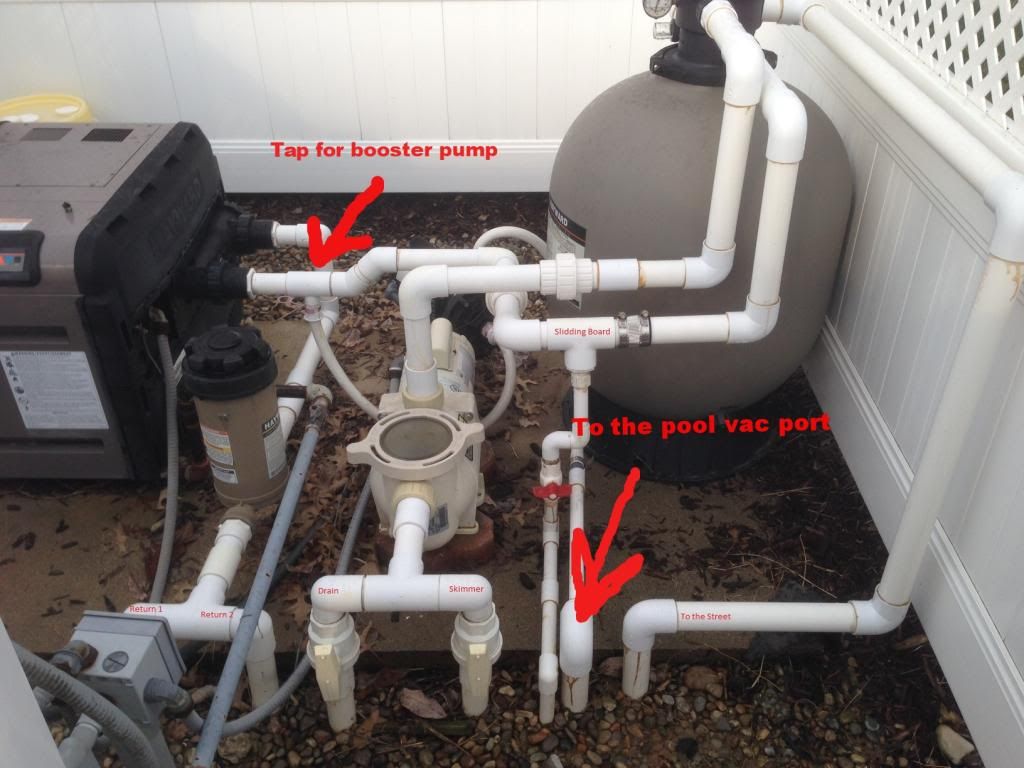

here are some pics... let me know if tapping into the line between the heater and filter will do...

My plumbing is all 1.5. I plan to make the manifold for the deck jets out of 1.5 and the runs will be 1.5 all the way to the wall and then 3/4 up to the surface to the jets.

My pump is a 3/4 HP pump

here are some pics... let me know if tapping into the line between the heater and filter will do...