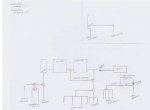

We are building a 40x20 pool + 8' dia spa with spillway into pool.

3 bubblers + 4 laminars.

2 skimmers.

We'll have 2 pumps: Main & Spa Jets

Main Pump will serve 3 purposes:

- Filtration during normal operations [(A) and (B) equally open; (C) 100% to Pool side; (D) bypassing heater; (F) closed; (G) 100% to Pool side; (H) open to circulate spa]

- Heating the spa (or pool) [(C) on Spa side; (D) open to heater; (E) and (F) closed, (G) open to Spa]

- Running water features [(A) and (B) equally on; (C) 100% to Pool side; (D) bypassing heater; (E) Diverting to the features, (F) equally open to both features]

The main pump will be in Mode 1 most of the time. When we want to use the spa, we'll kick it into Mode 2 for a short period of time. When we want to enjoy water features, which will likely only be for short periods of time, we can turn it into Mode 3.

We will only have a 50A circuit available at the pad. It looks like each pump is 16A Max Load, so that only leaves a little bit for the EasyTouch, LED Lights, and SWG.

Does this diagram look correct? What should we change on it?