I need some help designing the most efficient pump configuration for the following new pool.

Inground gunite pool capacity 8,700 gallons

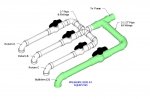

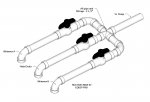

Main drain -32" Channel Drain in the floor: 236 GPM at 3.4 fps using a 2" Pvc dedicated pipe to the pump pad. (35')

2 Skimmers - Hayward SP1084 Auto Skim Series Skimmer 2-Inch Pvc dedicated pipe for each to the pump pad. (27' & 56')

Three 2" pvc returns with a dedicated pipe for each to the pump pad. (43', 35', & 60')

One dedicated vacuum line 2-Inch Pvc dedicated pipe for each to the pump pad. (45')

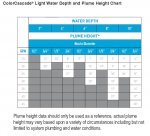

Three Pentair Colorcascade bubblers - 30 Gpm each - 1.5" Pvc to each bubbler. (55', 60', and 65')

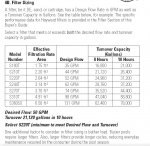

Sand Filter

Heat Pump heater

The use of the bubblers is intermittent not constant.

Using a 7 hour turnover rate I estimated 21 GPM for the pool.

It would seem either a two speed pump or a single pump with a booster might be indicated but the truth is I don' really know how to do the calcs, particularly the TDH.

Should the bubblers be plumbed individually back to the pad, or is some form of branch piping the best way?

Inground gunite pool capacity 8,700 gallons

Main drain -32" Channel Drain in the floor: 236 GPM at 3.4 fps using a 2" Pvc dedicated pipe to the pump pad. (35')

2 Skimmers - Hayward SP1084 Auto Skim Series Skimmer 2-Inch Pvc dedicated pipe for each to the pump pad. (27' & 56')

Three 2" pvc returns with a dedicated pipe for each to the pump pad. (43', 35', & 60')

One dedicated vacuum line 2-Inch Pvc dedicated pipe for each to the pump pad. (45')

Three Pentair Colorcascade bubblers - 30 Gpm each - 1.5" Pvc to each bubbler. (55', 60', and 65')

Sand Filter

Heat Pump heater

The use of the bubblers is intermittent not constant.

Using a 7 hour turnover rate I estimated 21 GPM for the pool.

It would seem either a two speed pump or a single pump with a booster might be indicated but the truth is I don' really know how to do the calcs, particularly the TDH.

Should the bubblers be plumbed individually back to the pad, or is some form of branch piping the best way?