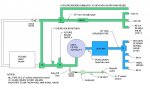

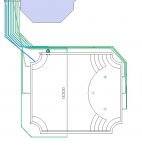

When the bubblers are on, it seems a three port actuator on the return side is in order to provide the 30 GPM each bubbler requires.

I suppose another three port actuator on the suction side to divert suction to the dedicated suction line.

Another possibility is an actuator for a bypass around the filter when the bubblers are on to relieve the pressure on the filter?

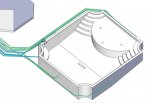

I'm trying to figure out what the TDH is for my design.

I'm looking for values for the following if anyone can provide.

Friction Losses for:

34" three port trench drain

Hayward skimmers

3/4" and 1" return eyeballs

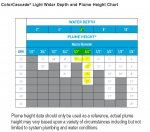

Colorcascade bubblers 15-30 GPM

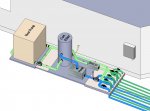

Pad plumbing assuming 2.5" pipe, check valves and other values like gauges.

Cartridge filter- still confused about the how to size because of the the divergent flows for bubbler on vs bubbler off, bypass maybe?

Salt water chlorine generator

Anything else ?

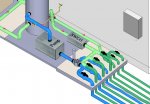

Also, I'm confused about suction side cleaners. I assume the suction is off when the cleaner is not being used. When it is in use, what kind of friction losses and flow are typical?

I suppose another three port actuator on the suction side to divert suction to the dedicated suction line.

Another possibility is an actuator for a bypass around the filter when the bubblers are on to relieve the pressure on the filter?

I'm trying to figure out what the TDH is for my design.

I'm looking for values for the following if anyone can provide.

Friction Losses for:

34" three port trench drain

Hayward skimmers

3/4" and 1" return eyeballs

Colorcascade bubblers 15-30 GPM

Pad plumbing assuming 2.5" pipe, check valves and other values like gauges.

Cartridge filter- still confused about the how to size because of the the divergent flows for bubbler on vs bubbler off, bypass maybe?

Salt water chlorine generator

Anything else ?

Also, I'm confused about suction side cleaners. I assume the suction is off when the cleaner is not being used. When it is in use, what kind of friction losses and flow are typical?