I'm looking for a way to add antifreeze to my Polaris return line.

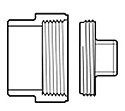

If I look at the terminating fitting on the return (see pic below) it looks like it might be threaded. I tried unthreading it to no avail, but not too hard as I didn't want to break anything.

If you look closely, you can see a cap that is definitely threaded into the end and it is cemented in ( I can see the purple primer) so no way that is unthreading. The connection I am asking about is the one I circled in red on the picture.

Can any of you PVC experts tell if that is a threaded fitting to the tee? If so I will try harder to unthread as that would be a perfect place to add the anti-freeze.

If I look at the terminating fitting on the return (see pic below) it looks like it might be threaded. I tried unthreading it to no avail, but not too hard as I didn't want to break anything.

If you look closely, you can see a cap that is definitely threaded into the end and it is cemented in ( I can see the purple primer) so no way that is unthreading. The connection I am asking about is the one I circled in red on the picture.

Can any of you PVC experts tell if that is a threaded fitting to the tee? If so I will try harder to unthread as that would be a perfect place to add the anti-freeze.