Not sure if this is the correct forum to post this question…

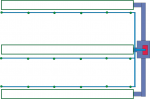

I am constructing 3 tanks, that will be used for hydroponics, that are 16 feet long, 1 foot wide and 2 feet deep. I will be installing 6 jets in each tank, 1 at each end and 4 distributed evenly along the long axis of the tank. I will have a separate "reservoir" tank, approx. 2 foot square by 3 feet high at one end of the middle tank, centered between the 3 tanks, so this reservoir tank will be inline with the center tank and about 1 foot away. The pump will draw water from this reservoir tank. Also, all three main tanks and the reservoir tank are connected together. Pump head will only be 1 foot or so. The 3 tanks will sit side by side, about 4 feet apart. I want to use 1 pump to power all 18 jets and use venturis to provide air to the water.

I plan on having one main manifold running perpendicular to the tank ends, three, sixteen foot branches coming off the main manifold and six jets coming off of each sixteen foot sub branch.

I am trying to determine what size pump would work for this configuration and what the pipe diameters should be for the manifolds.

Thanks

I am constructing 3 tanks, that will be used for hydroponics, that are 16 feet long, 1 foot wide and 2 feet deep. I will be installing 6 jets in each tank, 1 at each end and 4 distributed evenly along the long axis of the tank. I will have a separate "reservoir" tank, approx. 2 foot square by 3 feet high at one end of the middle tank, centered between the 3 tanks, so this reservoir tank will be inline with the center tank and about 1 foot away. The pump will draw water from this reservoir tank. Also, all three main tanks and the reservoir tank are connected together. Pump head will only be 1 foot or so. The 3 tanks will sit side by side, about 4 feet apart. I want to use 1 pump to power all 18 jets and use venturis to provide air to the water.

I plan on having one main manifold running perpendicular to the tank ends, three, sixteen foot branches coming off the main manifold and six jets coming off of each sixteen foot sub branch.

I am trying to determine what size pump would work for this configuration and what the pipe diameters should be for the manifolds.

Thanks