So, new to the board; have been lurking for a while; so grateful to have run into TFP and all the information and knowledge I have gained; figured it was time to post my SWCG install in case it can help someone else, or simply just to share.

It all started (as for many here I'm sure) with hot summer days (south-TX) and a pervasive algae problem :grrrr:; this is my second pool, at the previous home/pool, I rarely had problems with algae while using standard 3" trichlor tablets, a weekly calcium-hypochlorite based granular shock, the occasional dose of algaecide in the summer and infrequent brushing.

Since we built our new home/pool 3-1/2 yrs ago; very quickly algae started emerging..., I suspect the vast amount of organic material from the huge red-oak covering part of the pool and the combination of high CH constantly plugging off my off-line Rainbow-300 chlorinator output elbow as well as the mechanical 'disadvantage' of having an equipment pad sitting below water level was just a perfect storm (not to mention high CYA and phosphates building over time, and me using a crappy test kit). After trying / dumping money on the usual pool store stuff with phosphate binders and algaecides to no avail for two seasons, I had finally had it, and worse, I was not proud of my pool. I was determined to get rid of the green stuff. And then came TFP to the rescue . I considered just going BBB or getting a liquidator set-up, but then I figured, why not go all the way and get it over with.

. I considered just going BBB or getting a liquidator set-up, but then I figured, why not go all the way and get it over with.

I finally decided the best route for me would be a SWCG. I was clearly getting tired of the weekly workout brushing sessions , the constant shocking (Ca-HC), and the almost bi-weekly backwashing as the filter kept working overtime trapping the green mess; the idea of jugging bleach gallons quickly became unattractive, and the thought of having some peace of mind while away on vacation plus the reduced carbon footprint of having the chlorine being generated "in-house" finally sold me in.

, the constant shocking (Ca-HC), and the almost bi-weekly backwashing as the filter kept working overtime trapping the green mess; the idea of jugging bleach gallons quickly became unattractive, and the thought of having some peace of mind while away on vacation plus the reduced carbon footprint of having the chlorine being generated "in-house" finally sold me in.

Being the fact that I am a cheap monkey , and after reading some reviews here on different SWCGs, I decided to give the compupool 40K generic "T-cell 15" a shot. I already had a hayward/goldline pro-logic automation unit in place, so going with a hayward or replacement cell was the way to go, since all I needed was plumbing the cell. I really liked the Compupool's see-thru design; with the 3 yr warranty and since pool.supply.world had the T-cell 15 challenge going on here, I figured what the heck; so I got the cell for $365 and the P-kit (fittings and flow sensor) off E-bay for $83; so under $450 in parts and about $25 bucks in solar salt ($3 bucks per bag at the local Lowe's), I was ready to go.

, and after reading some reviews here on different SWCGs, I decided to give the compupool 40K generic "T-cell 15" a shot. I already had a hayward/goldline pro-logic automation unit in place, so going with a hayward or replacement cell was the way to go, since all I needed was plumbing the cell. I really liked the Compupool's see-thru design; with the 3 yr warranty and since pool.supply.world had the T-cell 15 challenge going on here, I figured what the heck; so I got the cell for $365 and the P-kit (fittings and flow sensor) off E-bay for $83; so under $450 in parts and about $25 bucks in solar salt ($3 bucks per bag at the local Lowe's), I was ready to go.

I started off by draining 1/2 the pool since my CH was at over 1000 ppm and CYA was around 110. (Phosphates were at 2500, but who cares, right?). I went to HF and got me a cheap 1/2 HP sump pump for $65 minus a 25% coupon, which did a great job.

and CYA was around 110. (Phosphates were at 2500, but who cares, right?). I went to HF and got me a cheap 1/2 HP sump pump for $65 minus a 25% coupon, which did a great job.

I then used water from the garage sink (part of the softener / home circuit) for the fill since my standard "outside" fill water tested at about 600 CH. (I plan to hard plumb a line from the garage to the fill line soon so I can chose which water to fill with based on the pool's water balance). I then shocked (with some Ca-Hypochlorite that I had laying around) and tested / balanced (DPD kit from Leslie's while I get a K-2006); then tested for salt (K-1766) and to my surprise I was already at 1000 ppm; added 280 Lbs of solar crystals which brought me to 3300 ppm; I then shut off the tablet chlorinator and allowed my FC to fall to 0.5 while I waited for the cell and P-kit to arrive in the mail; and....... ready to cut and glue some PVC.

The original set-up:

Removing the Rainbow-300; I used two regulator valves to plug the 1/4" intake/output lines (I had a spare valve laying around, so that worked, at least for now; this way I can always get the Rainbow out again if need be for an emergency - hopefully never).

The retiring 300 on top of the now obsolete 3" tablet bucket; - she served me well! - not.

- she served me well! - not.

The return line to be operated on. (notice I used the three way valve to close off this section, as the ball-valve had to go to make space for the cell and the flow sensor's T).

Out with the hacksaw; of course, having an assistant at hand is always nice :-D . (btw, I did use a heat gun on that cut ball valve and salvaged it for later in case I ever need it).

My 3 y/o dtr:

And the other helper

Checking the flow sensor for clearance with the valve actuator. Check!.

A few minutes spent measuring / cutting / deburring and cleaning the pipes; some fresh glue and the line was ready for the cell:

The offset design of the cell worked out perfectly with my piping since the line in to the heater was slightly on the way:

While at Lowe's, I got me a $3 2" plug for when it's time to clean the cell; I still have not figured out how to build my own dummy cell in case I ever need one..... thanks to hayward and their proprietary thread sizes. I may give in and buy their dummy cell I guess.

I used some silicone for the O-rings on the cell fittings; 30 min of cure time for the glue; tested for leaks, check!; then plugged it to the pro-logic, and BAM!, I was generating :

:

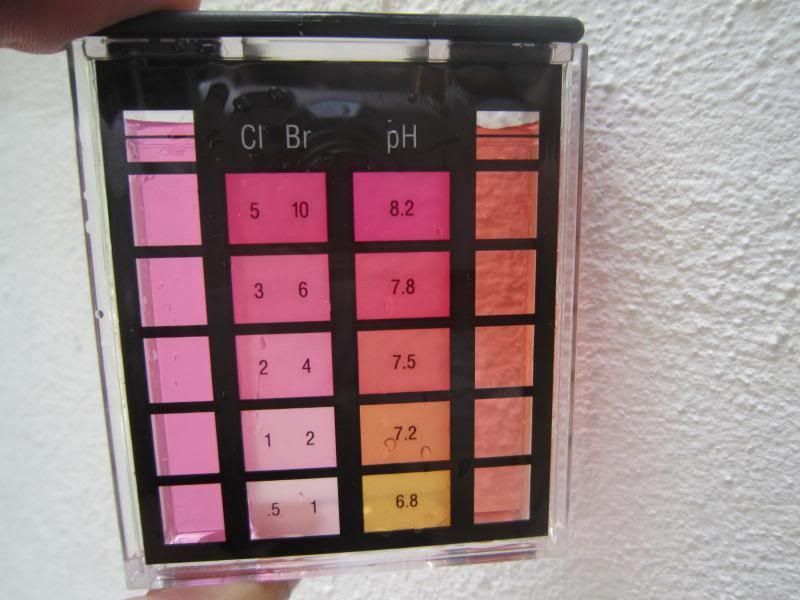

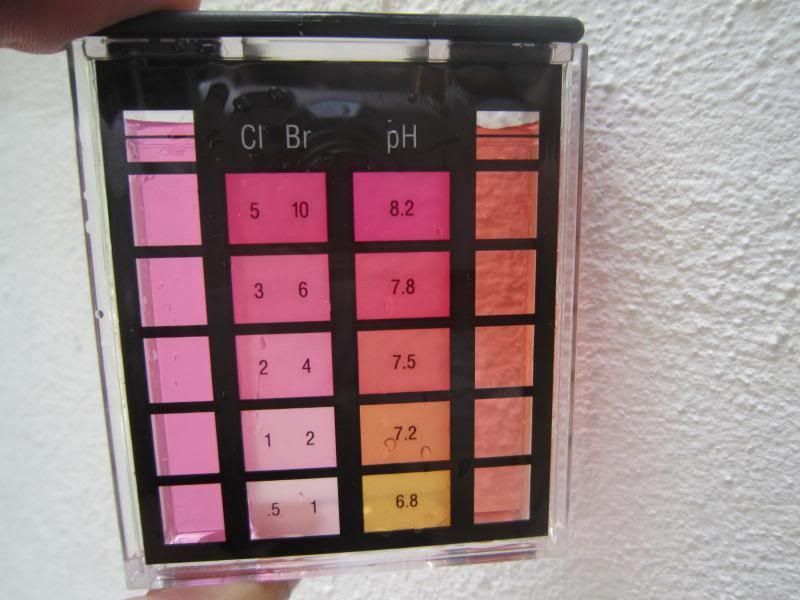

This was a sample off one of the pool returns virtually 2 minutes after firing up the cell (FC was at 0.5 right before):

Why I did it:

I couldn't be any happier; it's been nearly a week now of crystal clear water, FC is at 4 ppm (CYA-60) with an 8 hr pump time (4h AM, 4h evening) with three digit temps (August) here in south-TX, and the cell at 60%. No issues with the compupool 40K cell so far, but I plan on keeping this thread updated if issues arise and provide a long term review on the cell. The only thing I have noticed is the ProLogic enclosure / control panel running hotter than I would like (expected with the chlorinator now running), and having read about the circuit board issues / burn solder joints etc, I'm planning on fitting a 12v fan or heat sink of sorts at some point just to be on the safe side. Time will tell, but so far things look pretty good.

It all started (as for many here I'm sure) with hot summer days (south-TX) and a pervasive algae problem :grrrr:; this is my second pool, at the previous home/pool, I rarely had problems with algae while using standard 3" trichlor tablets, a weekly calcium-hypochlorite based granular shock, the occasional dose of algaecide in the summer and infrequent brushing.

Since we built our new home/pool 3-1/2 yrs ago; very quickly algae started emerging..., I suspect the vast amount of organic material from the huge red-oak covering part of the pool and the combination of high CH constantly plugging off my off-line Rainbow-300 chlorinator output elbow as well as the mechanical 'disadvantage' of having an equipment pad sitting below water level was just a perfect storm (not to mention high CYA and phosphates building over time, and me using a crappy test kit). After trying / dumping money on the usual pool store stuff with phosphate binders and algaecides to no avail for two seasons, I had finally had it, and worse, I was not proud of my pool. I was determined to get rid of the green stuff. And then came TFP to the rescue

. I considered just going BBB or getting a liquidator set-up, but then I figured, why not go all the way and get it over with.

. I considered just going BBB or getting a liquidator set-up, but then I figured, why not go all the way and get it over with.I finally decided the best route for me would be a SWCG. I was clearly getting tired of the weekly workout brushing sessions

, the constant shocking (Ca-HC), and the almost bi-weekly backwashing as the filter kept working overtime trapping the green mess; the idea of jugging bleach gallons quickly became unattractive, and the thought of having some peace of mind while away on vacation plus the reduced carbon footprint of having the chlorine being generated "in-house" finally sold me in.

, the constant shocking (Ca-HC), and the almost bi-weekly backwashing as the filter kept working overtime trapping the green mess; the idea of jugging bleach gallons quickly became unattractive, and the thought of having some peace of mind while away on vacation plus the reduced carbon footprint of having the chlorine being generated "in-house" finally sold me in.Being the fact that I am a cheap monkey

I started off by draining 1/2 the pool since my CH was at over 1000 ppm

I then used water from the garage sink (part of the softener / home circuit) for the fill since my standard "outside" fill water tested at about 600 CH. (I plan to hard plumb a line from the garage to the fill line soon so I can chose which water to fill with based on the pool's water balance). I then shocked (with some Ca-Hypochlorite that I had laying around) and tested / balanced (DPD kit from Leslie's while I get a K-2006); then tested for salt (K-1766) and to my surprise I was already at 1000 ppm; added 280 Lbs of solar crystals which brought me to 3300 ppm; I then shut off the tablet chlorinator and allowed my FC to fall to 0.5 while I waited for the cell and P-kit to arrive in the mail; and....... ready to cut and glue some PVC.

The original set-up:

Removing the Rainbow-300; I used two regulator valves to plug the 1/4" intake/output lines (I had a spare valve laying around, so that worked, at least for now; this way I can always get the Rainbow out again if need be for an emergency - hopefully never).

The retiring 300 on top of the now obsolete 3" tablet bucket;

- she served me well! - not.

- she served me well! - not.

The return line to be operated on. (notice I used the three way valve to close off this section, as the ball-valve had to go to make space for the cell and the flow sensor's T).

Out with the hacksaw; of course, having an assistant at hand is always nice :-D . (btw, I did use a heat gun on that cut ball valve and salvaged it for later in case I ever need it).

My 3 y/o dtr:

And the other helper

Checking the flow sensor for clearance with the valve actuator. Check!.

A few minutes spent measuring / cutting / deburring and cleaning the pipes; some fresh glue and the line was ready for the cell:

The offset design of the cell worked out perfectly with my piping since the line in to the heater was slightly on the way:

While at Lowe's, I got me a $3 2" plug for when it's time to clean the cell; I still have not figured out how to build my own dummy cell in case I ever need one..... thanks to hayward and their proprietary thread sizes. I may give in and buy their dummy cell I guess.

I used some silicone for the O-rings on the cell fittings; 30 min of cure time for the glue; tested for leaks, check!; then plugged it to the pro-logic, and BAM!, I was generating

:

:

This was a sample off one of the pool returns virtually 2 minutes after firing up the cell (FC was at 0.5 right before):

Why I did it:

I couldn't be any happier; it's been nearly a week now of crystal clear water, FC is at 4 ppm (CYA-60) with an 8 hr pump time (4h AM, 4h evening) with three digit temps (August) here in south-TX, and the cell at 60%. No issues with the compupool 40K cell so far, but I plan on keeping this thread updated if issues arise and provide a long term review on the cell. The only thing I have noticed is the ProLogic enclosure / control panel running hotter than I would like (expected with the chlorinator now running), and having read about the circuit board issues / burn solder joints etc, I'm planning on fitting a 12v fan or heat sink of sorts at some point just to be on the safe side. Time will tell, but so far things look pretty good.